Micro-nano graded porous copper and preparation method thereof

A graded porous, micro-nano technology, applied in the preparation of micro-nano graded porous copper, the field of micro-nano graded porous copper, can solve the problems of uneven pore structure, high cost, complicated operation, etc., to improve gas-liquid flow and ion exchange. The effect of speed, large specific surface area and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

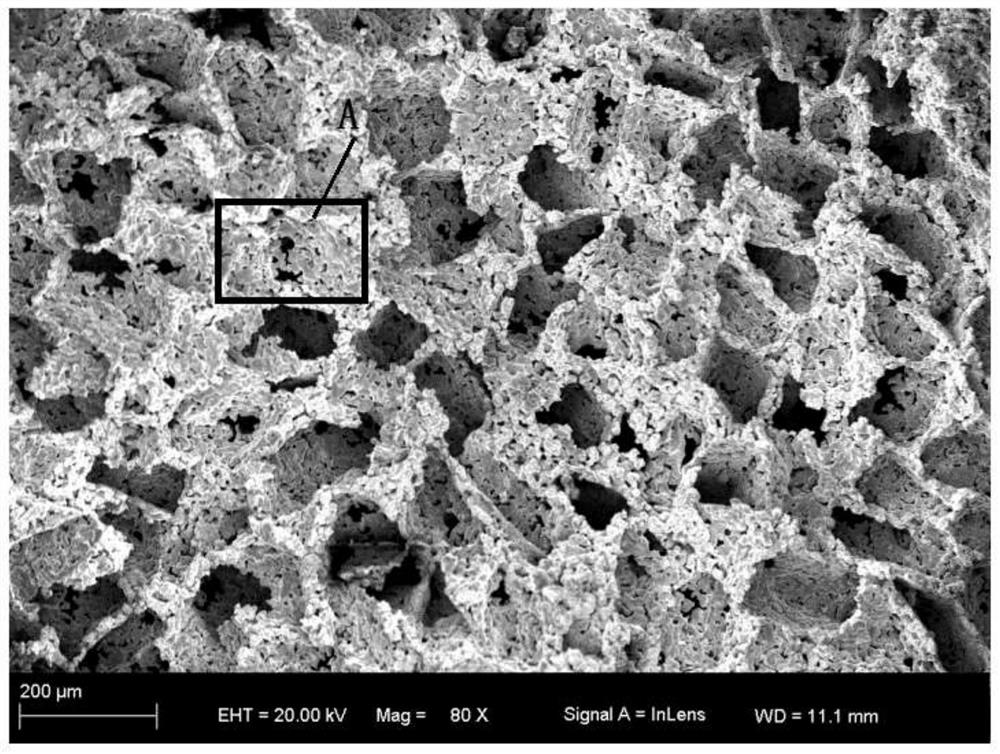

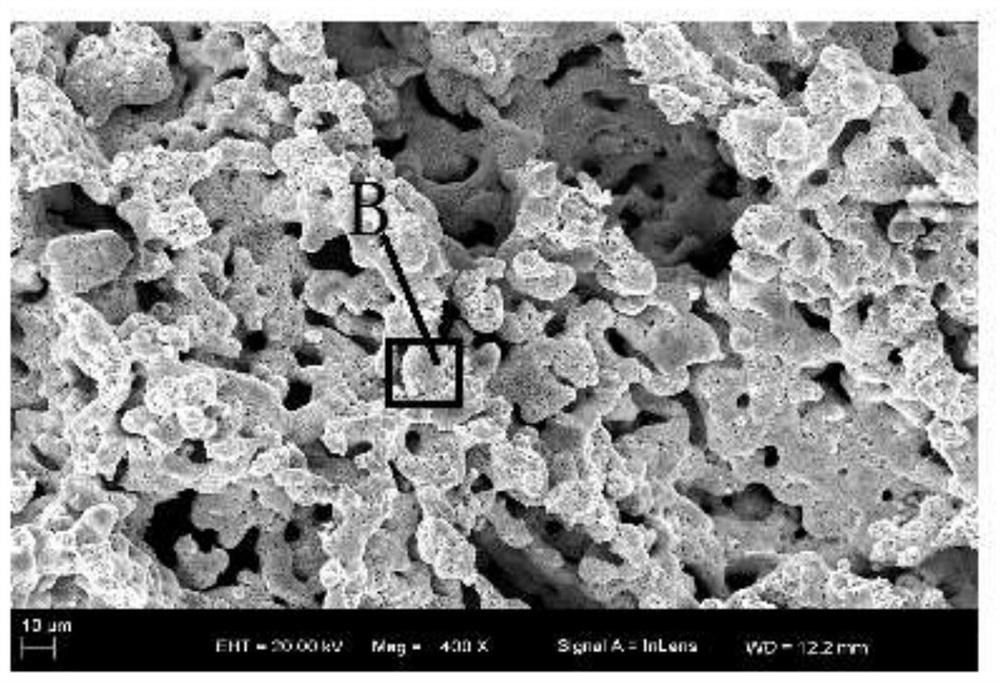

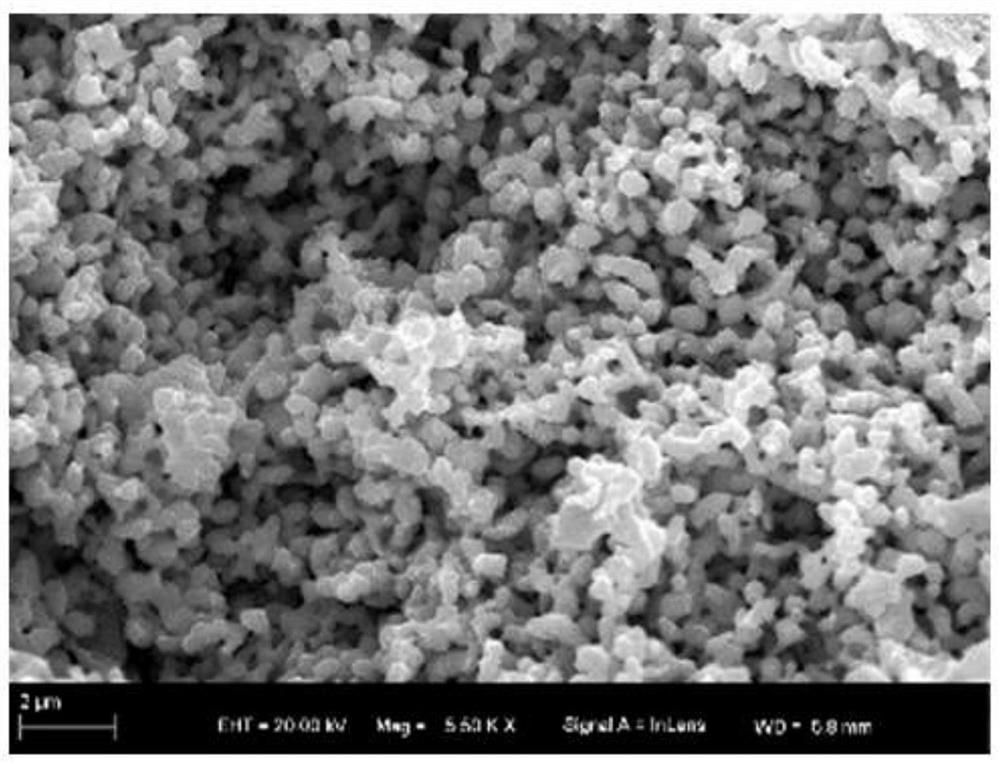

[0028] The invention discloses a method for preparing micro-nano graded porous copper. The preparation method is a combination of adding a pore-forming agent method and a dealloying method, and is specifically implemented according to the following steps:

[0029] Step 1. Weigh copper powder, manganese powder and sodium chloride particles in a certain proportion, and mix the powder evenly;

[0030] In step 1, the molar ratio of copper powder to manganese powder is 4:6-5:5.

[0031] In step 1, the amount of NaCl particles accounts for 60-80vol% of the total volume of the three raw materials of copper powder, manganese powder and sodium chloride particles.

[0032] In step 1, the powder mixing time is 4-8h.

[0033] Step 2. Fill the uniformly mixed powder in step 1 into the mold, press with a certain pressure, and hold the pressure for a certain period of time;

[0034] In step 2, the molding pressure is 2-20MPa, and the holding time is 1min;

[0035] Step 3. Place the sample...

Embodiment 1

[0044] Step 1: Weigh copper powder and manganese powder with a molar ratio of 5:5, and weigh 60 vol% of the total volume ratio of sodium chloride particles, and mix the powder for 8 hours.

[0045] Step 2: Weigh the uniformly mixed powder and fill it into a mold, press at a pressure of 10 MPa, and hold the pressure for 1 min.

[0046] Step 3: Place the pressed sample in a high-temperature tube furnace for sintering at a heating rate of 10°C / min. The sintering temperature is 870°C, keep it warm for 4 hours, and take out the sample after cooling with the furnace. The whole process is protected by argon gas.

[0047] Step 4, polish the surface of the sintered sample on sandpaper, and place it in a water bath with a constant temperature of 60° C. for immersion.

[0048] Step 5, take out the sample after water immersion, and then place it in 0.1mol / L HCl solution for dealloying. The dealloying process is carried out in a water bath at a constant temperature of 70°C. No obvious bub...

Embodiment 2

[0051] Step 1: Weigh copper powder and manganese powder with a molar ratio of 5:5, and weigh 70 vol% of the total volume ratio of sodium chloride particles, and mix the powder for 4 hours.

[0052] Step 2: Weigh the uniformly mixed powder and fill it into a mold, press with a pressure of 2MPa, and hold the pressure for 1min.

[0053] Step 3: Place the pressed sample in a high-temperature tube furnace for sintering at a heating rate of 10°C / min, the sintering temperature is 820°C, keep it warm for 4 hours, and take out the sample after cooling with the furnace. The whole process is protected by argon gas.

[0054] Step 4: Polish the surface of the sintered sample on sandpaper to make it bright, and place it in a water bath with a constant temperature of 60° C. for water immersion.

[0055] Step 5, take out the sample after water immersion, and then place it in 0.1mol / L HCl solution for dealloying. The dealloying process is carried out at a constant temperature of 70°C in a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com