Environment-friendly plastic and preparation method thereof

A technology of environmentally friendly plastics and raw materials, applied in the field of polymer materials, can solve problems such as oxidation resistance, weak impact resistance, difficulty in large-scale production, and large consumption of agricultural products, achieving good oxidation resistance, low environmental pollution, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

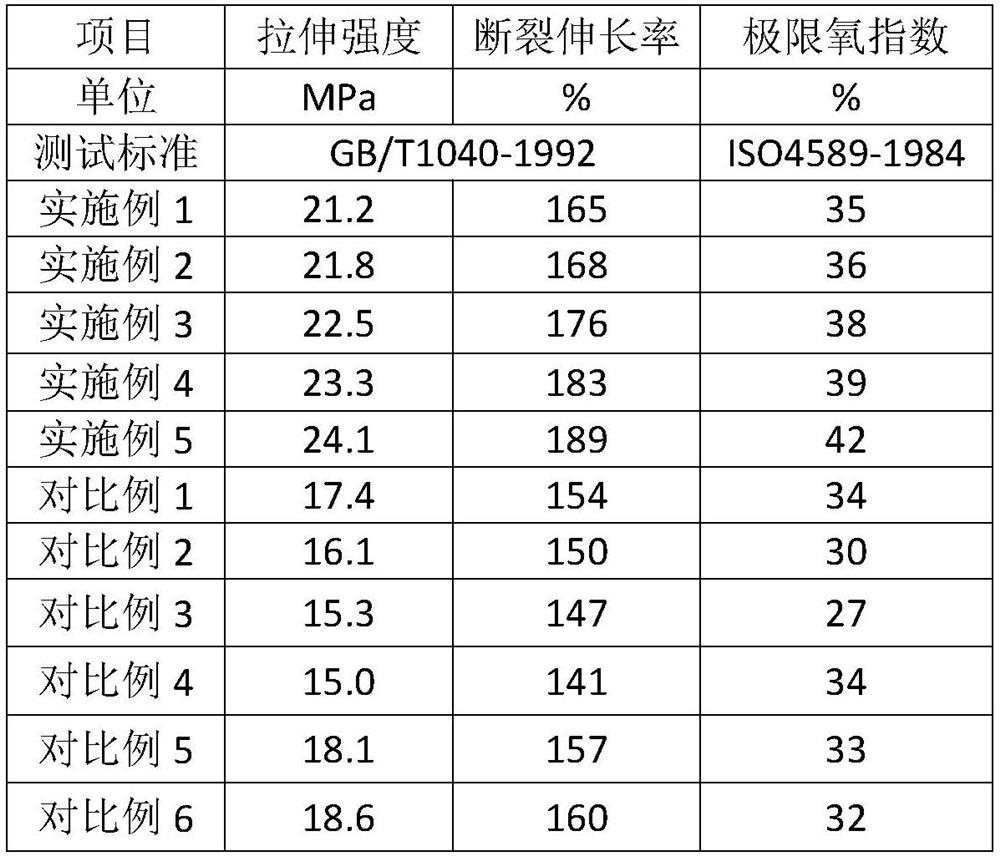

Examples

Embodiment 1

[0027] An environmentally friendly plastic, characterized in that it is made from the following raw materials in parts by weight: 15 parts of cinnamic acid modified plant fibers, 30 parts of vinyl β-cyclodextrin quaternary ammonium salt, 2-vinylpyrazine / Methyl vinyl silfluorene / 1,3-adamantane diol monoacrylate copolymer 45 parts, azobisisobutyronitrile 1 part, epoxy succinic acid 4 parts, epoxy-terminated hyperbranched polyphosphate 5 share.

[0028] The preparation method of the cinnamic acid modified plant fiber comprises the following steps: adding plant fiber and cinnamic acid to N,N-dimethylformamide, and then adding 4-dimethylaminopyridine, 1-ethyl -(3-Dimethylaminopropyl) carbodiimide hydrochloride, stirred and reacted at 50°C for 6 hours, then precipitated in water, and then dried the precipitated polymer in a vacuum oven at 80°C To constant weight, obtain cinnamic acid modified plant fiber; said plant fiber, cinnamic acid, N,N-dimethylformamide, 4-dimethylaminopyrid...

Embodiment 2

[0032] An environmentally friendly plastic, characterized in that it is made from the following raw materials in parts by weight: 17 parts of cinnamic acid modified plant fibers, 32 parts of vinyl β-cyclodextrin quaternary ammonium salts, 2-vinylpyrazine / Methyl vinyl silfluorene / 1,3-adamantane diol monoacrylate copolymer 48 parts, azobisisoheptanonitrile 1.2 parts, epoxy succinic acid 4.5 parts, epoxy-terminated hyperbranched polyphosphate 6 share.

[0033] The preparation method of the cinnamic acid modified plant fiber comprises the following steps: adding plant fiber and cinnamic acid to tetrahydrofuran, then adding 4-dimethylaminopyridine, 1-ethyl-(3-dimethylamino Propyl) carbodiimide hydrochloride, stirred and reacted at 53°C for 7 hours, then precipitated in water, and then dried the precipitated polymer to constant weight in a vacuum oven at 83°C to obtain modified cinnamic acid Plant fiber; the mass ratio of the plant fiber, cinnamic acid, THF, 4-dimethylaminopyridin...

Embodiment 3

[0037] An environmentally friendly plastic, characterized in that it is made from the following raw materials in parts by weight: 20 parts of cinnamic acid modified plant fibers, 35 parts of vinyl β-cyclodextrin quaternary ammonium salts, 2-vinylpyrazine / Methyl vinyl silfluorene / 1,3-adamantane diol monoacrylate copolymer 50 parts, azobisisobutyronitrile 1.5 parts, epoxy succinic acid 5 parts, epoxy-terminated hyperbranched polyphosphate 6.5 parts share.

[0038] The preparation method of the cinnamic acid modified plant fiber comprises the following steps: adding plant fiber and cinnamic acid to N-methylpyrrolidone, then adding 4-dimethylaminopyridine, 1-ethyl-(3- Dimethylaminopropyl) carbodiimide hydrochloride, stirred and reacted at 55°C for 8 hours, then precipitated in water, then dried the precipitated polymer to constant weight at 85°C in a vacuum oven, Obtain cinnamic acid modified plant fiber; said plant fiber, cinnamic acid, N-methylpyrrolidone, 4-dimethylaminopyrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com