Entrained-flow bed coal gasification black water advanced treatment process

A treatment process and black water technology, applied in the field of coal chemical industry, can solve the problems of fouling and clogging, reducing emission reduction effect, corrosion of gasification system pipelines and equipment, etc., to avoid easy fouling of electrodes, reduce chemical consumption, reduce effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

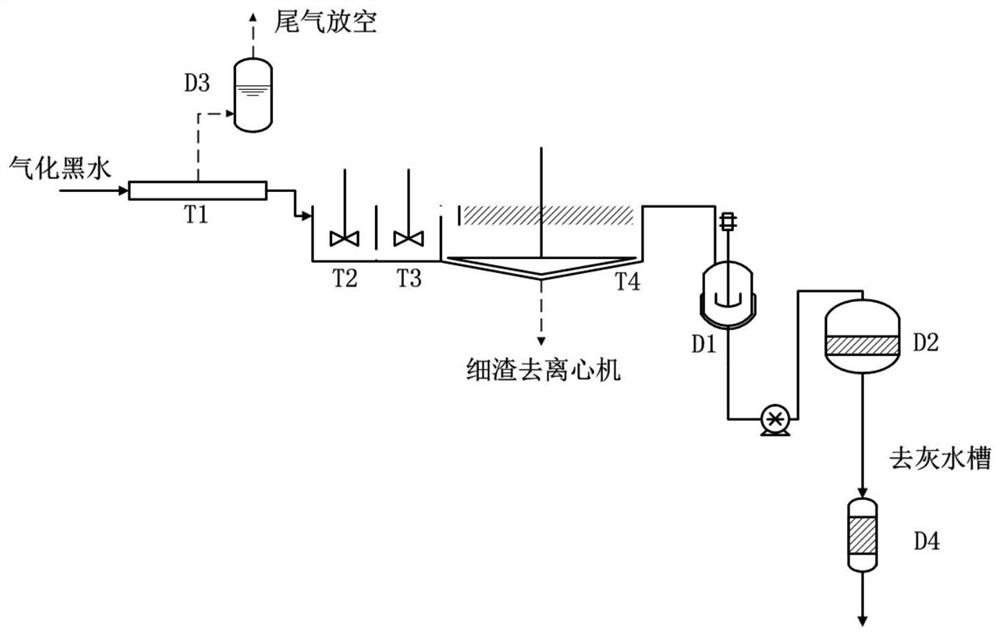

[0045] like figure 1 As shown, the gasified black water is drawn from the flash evaporation system, pressurized to 0.3MPa by the pump, and then enters the electromagnetic reaction tank T1, with a flow rate of 450m 3 / h, the black water velocity in the pool is 5.5m / s. The total length of the electromagnetic reaction pool is 30m, the section is rectangular, the width is 0.15m, and the height is 0.2m. The reaction pool is made of carbon steel, and the bottom and top are lined with epoxy resin coating. The magnetic field strength in the reaction cell is 1.5T. The gas produced in the reaction process is drawn from the air duct at the top of the electromagnetic reaction pool, and enters the absorption tank D3 to remove chlorine gas, and the absorption tank is equipped with 30% sodium hydroxide solution.

[0046] After the gasified black water exits the electromagnetic reaction tank, it enters the T2 coagulation tank through the angle valve and enters the T2 coagulation tank. The s...

Embodiment 2

[0055] The main difference between this embodiment and Embodiment 1 is that the flow velocity of the black water entering the electromagnetic reaction pool is adjusted to 3.5m / s, and the magnetic field strength in the reaction pool is 2.5T.

[0056] The addition amount of magnesium oxide slurry in the coagulation tank is 40 mg / L on a dry basis;

[0057] The dry base dosage of polysilicate aluminum iron and aluminum coagulant is 300mg / L, the average residence time of black water in the T2 coagulation tank is 30min, and the stirring intensity in the tank is 150s -1 . The black water in T2 enters the T3 flocculation tank through the channel at the bottom of the partition, and the flocculant cationic polyacrylamide (molecular weight 6 million) is added to the flocculation tank, and the addition amount is 8mg / L. The average residence time of the black water in the T3 flocculation tank is 20min, and the tank is stirred The shear strength is 50s -1 , The average residence time in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com