Apatite microcarrier and preparation method and application thereof

An apatite and microcarrier technology, which can be applied in general culture methods, biochemical equipment and methods, chemical instruments and methods, etc. The effect of good stability and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

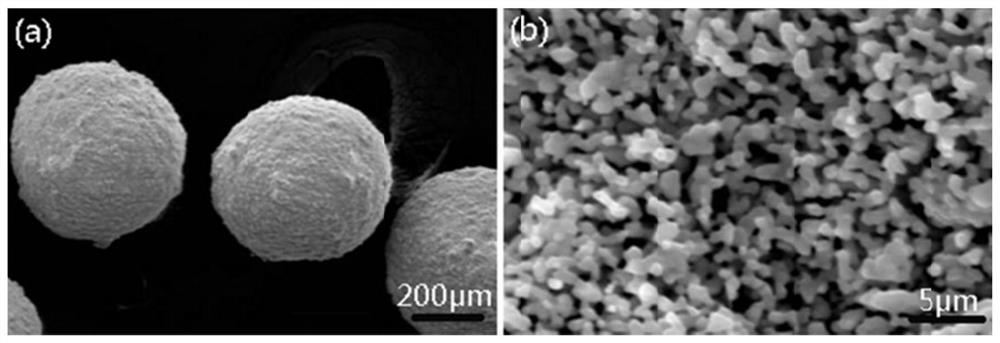

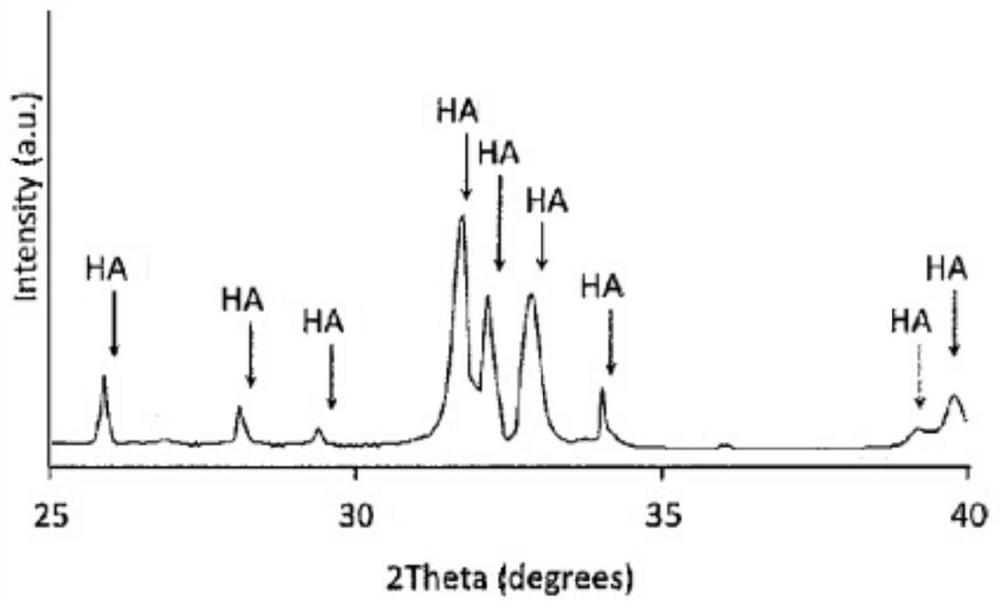

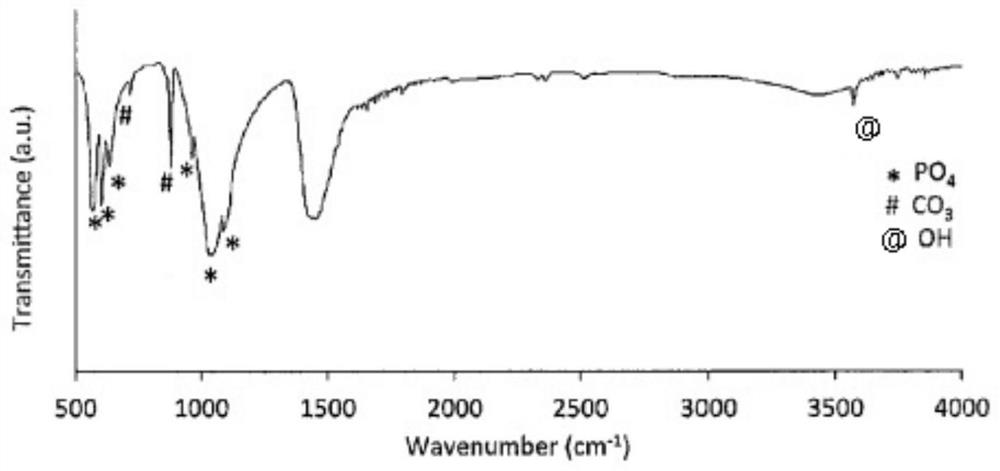

[0047] Embodiment 1: the preparation of apatite microcarrier

[0048] A preparation method of apatite microcarrier, comprising the following steps:

[0049] (1) Add hydroxyapatite powder (synthesized by wet precipitation method) to solution A (solution A is mannuronic acid and guluronic acid dissolved in deionized water at a mass ratio of 1.56:1) , the concentration is 0.035g / mL), the mass of hydroxyapatite powder is 45% of the mass of solution A, then starch is added, the mass of starch is 40% of the mass of solution A, and stirred for 10min to obtain suspension B ;

[0050] (2) Extrude the suspension B prepared in step (1) dropwise through a droplet device (a droplet device controlled by an air-assisted electric valve) (the valve is opened at 6ms and closed at 90ms for extrusion) and added dropwise Concentration is in the calcium chloride solution of 0.5mol / L, forms pearl a, washes pearl a twice with deionized water then, then pearl a is placed in the isopropanol solution ...

Embodiment 2

[0054] Embodiment 2: the preparation of apatite microcarrier

[0055] A preparation method of apatite microcarrier, comprising the following steps:

[0056] (1) Add silicon ion-substituted hydroxyapatite powder (silicon ion-substituted hydroxyapatite powder synthesized by wet precipitation method) into solution A (solution A is calcium alginate dissolved in deionized water, the concentration is 0.03g / mL), the mass of hydroxyapatite powder replaced by silicon ions is 45% of the mass of solution A, then starch is added, the mass of starch is 40% of the mass of solution A, and stirred for 10min to obtain suspension B;

[0057] (2) Extrude the suspension B prepared in step (1) dropwise through a droplet device (a droplet device controlled by an air-assisted electric valve) (the valve is opened at 6ms and closed at 90ms for extrusion) and added dropwise Concentration is in the calcium chloride solution of 0.5mol / L, forms pearl a, washes pearl a twice with deionized water then, th...

Embodiment 3

[0058] Embodiment 3: the preparation of apatite microcarrier

[0059] A preparation method of apatite microcarrier, comprising the following steps:

[0060] (1) Add tricalcium phosphate powder (tricalcium phosphate powder synthesized by wet precipitation method) into solution A (solution A is calcium alginate dissolved in deionized water, concentration is 0.03g / mL) to disperse, the tricalcium phosphate powder The mass is 45% of the mass of solution A, then add amphene, the mass of camphene is 40% of the mass of solution A, stir for 10min, obtain suspension B;

[0061] (2) Extrude the suspension B prepared in step (1) dropwise through a droplet device (a droplet device controlled by an air-assisted electric valve) (the valve is opened at 6ms and closed at 90ms for extrusion) and added dropwise Concentration is in the calcium chloride solution of 0.5mol / L, forms pearl a, washes pearl a twice with deionized water then, then pearl a is placed in the isopropanol solution containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com