Centrifugal atomization rotating disc, centrifugal atomization device and centrifugal atomization method

A technology of centrifugal atomization and rotating disk, which is applied in the field of metal powder making equipment, can solve the problems of centrifugal atomization that cannot be carried out continuously and stably, pitting and staining, and achieve uniform size, reduce pitting, and stable preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

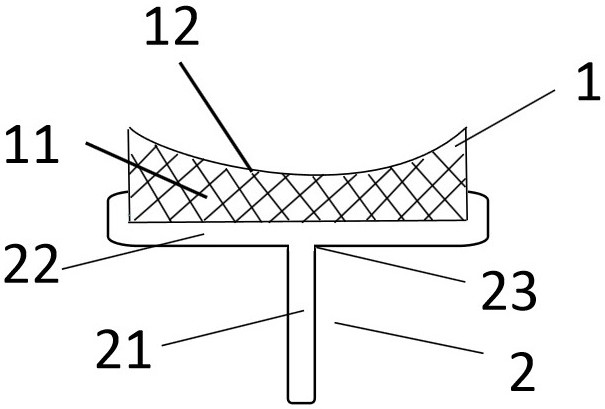

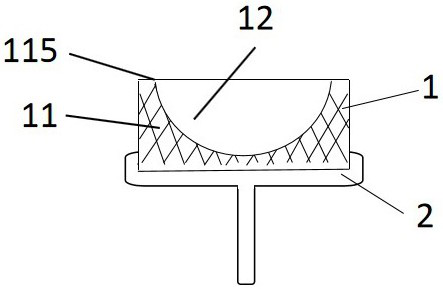

[0055] Example 1: The disc core is made of high-strength graphite (Shanghai Toyo TTK-4), and the disc core is as follows figure 1 As shown, the disc core is a butterfly-shaped accommodation space with arc edges, the bracket is made of TC4 titanium alloy, the metal liquid is tin-based solder metal Sn5Pb92.5Ag2.5, and the fluid atomization temperature is 520 0 C (Celsius). The diameter of the disc core is 50mm, the rotational speed of the disc core is 45000rpm (revolution per minute), the linear velocity is 118m / s (meter per second), the continuous atomization is 8h (hour), and the flow rate is 200kg / h (kilogram per hour) , The obtained powder is measured by the European and American laser particle size analyzer LS-6, and the powder D1O=15μm (micron), D50=30μm, D90=50μm.

Embodiment 2

[0057] Embodiment 2: Apply the high-temperature metal atomization disk core in this application, the disk core is made of zirconia ceramics, the disk core is as figure 1 As shown, the disk core is a butterfly-shaped storage space with arc edges, the bracket is made of TC4 titanium alloy, the metal liquid is copper liquid, and the atomization temperature is 1200 0 C, the diameter of the turntable is 40mm, the rotation speed of the disk core is 50000rpm, the edge line speed of the disk core is 105m / s, the continuous atomization is 8h, the flow rate is 150kg / h, and the obtained powder is measured by the European and American laser particle size analyzer LS-6. D50=32μm, D90=51μm.

Embodiment 3

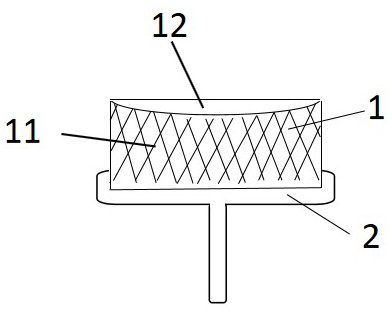

[0059] Embodiment 3: Using the high-temperature metal atomization disk core of the present application, the disk core is made of zirconia ceramics, the bracket is made of TC10 titanium alloy, the diameter of the disk core is 35mm, and the disk core is as follows Figure 5 As shown, the disc core is a conical bucket-shaped arc side disc, the angle of the cone bucket top angle is 120°, the rotational speed of the disc core is 55000rpm, and the linear velocity of the arc edge of the disc core is 100m / s. The atomized high-speed metal It is stainless steel 304, the atomization temperature is 1600 0 C, the flow rate is 150kg / h, continuous atomization for 4h, the obtained powder is measured as D1O=9μm, D50=30μm, D90=60μm. After sieving, the required 3D printing powder with a size distribution of 25 μm to 45 μm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com