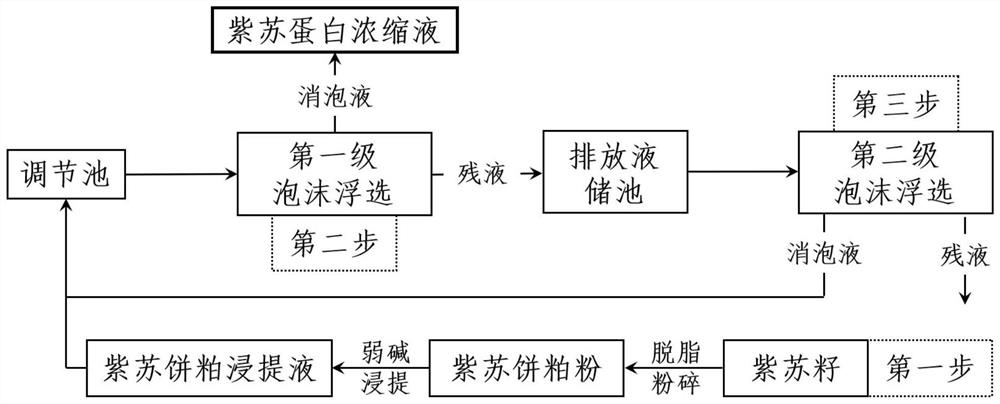

Two-stage froth flotation method for concentrating and separating protein in purple perilla cakes

A technology of froth flotation and perilla cake, which is applied in the fields of peptide preparation, chemical instruments and methods, organic chemistry, etc., can solve the problems of easily polluted environment, complicated process, poor concentration effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

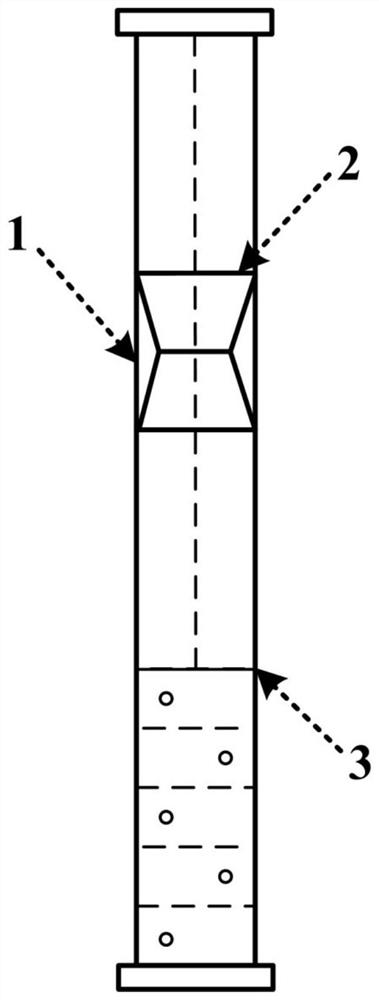

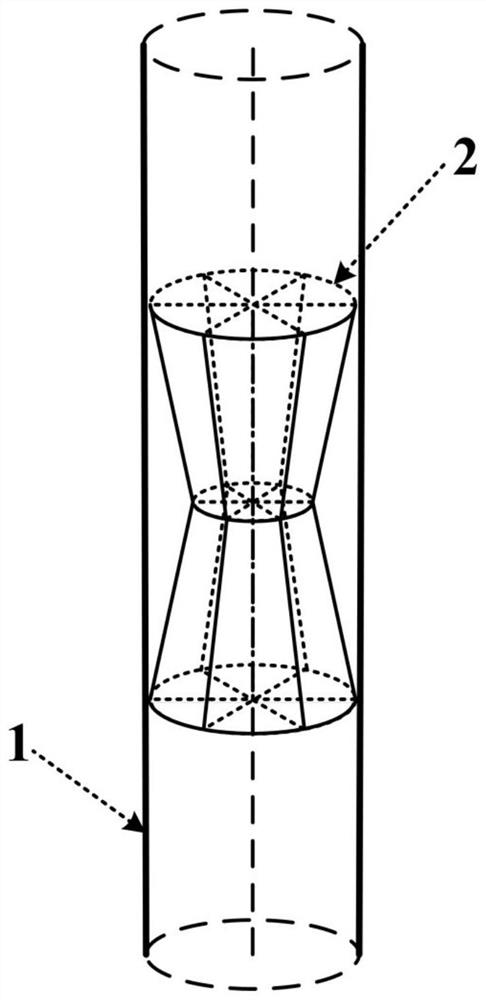

[0066] Embodiment 1: the first stage froth flotation tower

[0067] A froth flotation tower (such as figure 2 , 3 As shown), it comprises a hollow cylindrical foam flotation column 1 with a diameter of 50mm and a height of 1.3m, and an hourglass-shaped member 2 is installed in the foam flotation column 1, and the hourglass-shaped member 2 consists of two equivalent Hollow, bottomless round platform top edge butt joint structure, bottom edge seamlessly connected with the inner wall of the foam flotation column 11, the top diameter of the round platform is 1 / 2 of the bottom surface diameter, the bottom surface diameter is 50mm, and the hourglass-shaped member 2 The vertical height is 225mm, and the junction of the two circular frustums is located in the middle of the foam phase.

[0068] Among them, the material of the hourglass-shaped component is a plastic sheet with a thickness of 1mm. The sheet is made into a hollow round platform through a conventional thermoplastic proc...

Embodiment 2

[0069] Embodiment 2: the first stage froth flotation tower

[0070] A froth flotation tower (such as figure 2 , 3 As shown), it comprises a hollow cylindrical foam flotation column 1 with a diameter of 50mm and a height of 1.3m, and an hourglass-shaped member 2 is installed in the foam flotation column 1, and the hourglass-shaped member 2 consists of two equivalent Hollow, bottomless round platform top edge butt joint structure, bottom edge seamlessly connected with the inner wall of the foam flotation column 11, the top diameter of the round platform is 1 / 2 of the bottom surface diameter, the bottom surface diameter is 50mm, and the hourglass-shaped member 2 The vertical height is 200mm, and the junction of the two circular frustums is located in the middle of the foam phase.

[0071] Among them, the material of the hourglass-shaped component is a plastic sheet with a thickness of 1mm. The sheet is made into a hollow round platform through a conventional thermoplastic proc...

Embodiment 3

[0072] Embodiment 3: the first stage froth flotation tower

[0073] A froth flotation tower (such as figure 2 , 3 As shown), it comprises a hollow cylindrical foam flotation column 1 with a diameter of 50mm and a height of 1.3m, and an hourglass-shaped member 2 is installed in the foam flotation column 1, and the hourglass-shaped member 2 consists of two equivalent Hollow, bottomless round platform top edge butt joint structure, bottom edge seamlessly connected with the inner wall of the foam flotation column 11, the top diameter of the round platform is 1 / 2 of the bottom surface diameter, the bottom surface diameter is 50mm, and the hourglass-shaped member 2 The vertical height is 250mm, and the junction of the two circular frustums is located in the middle of the foam phase.

[0074] Among them, the material of the hourglass-shaped component is a plastic sheet with a thickness of 1mm. The sheet is made into a hollow round platform through a conventional thermoplastic proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com