In-situ EBSD observation method for microscopic orientation evolution of recrystallized grains of magnesium alloy

A technology for recrystallization and magnesium alloys, which is applied in the field of in-situ EBSD observation of the evolution of recrystallized grains of magnesium alloys. The effect of low performance, low sample preparation technical requirements, and high experimental success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In-situ EBSD observation method was used to study the grain micro-orientation evolution of cold-rolled Mg-2.0Zn-0.62GD (wt.%) alloy during recrystallization. Samples with the size of 12mm (rolling direction, RD)×8mm (transverse direction, TD)×2mm (normal direction, ND) were cut from the cold-rolled sheet, and the following steps were followed:

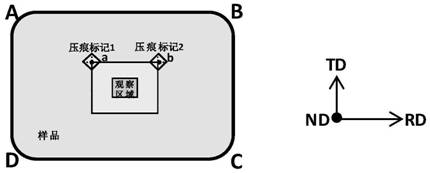

[0030] Step (1): sequentially using 240#, 400#, 1000#, 2000#, 3000# and 5000# sandpaper to pre-grind the rolling surface of the above samples, and mechanically polishing with a diamond polishing paste with a particle size of 1.5μm; Put the sample on the sample table of micro Vickers hardness tester, and set the load of 1000g and the loading time of 15s, such as Figure 1 Two indentation mark points A and B with a distance of 1500μm are prepared at the position where the rolled surface of the sample is slightly deviated from the edge ab, so that the central connecting line AB is parallel to the edge AB of the sample;

[0031] Step (2)...

Embodiment 2

[0041] In-situ EBSD observation method was used to study the grain micro-orientation evolution during the recrystallization grain growth of cold-rolled Mg-1.73Zn-0.78GD (wt.%) alloy. A sample of 12mm (rolling direction, RD)×8mm (transverse direction, TD)×2mm (normal direction, ND) was cut from the cold-rolled sheet, heat-treated at 350℃ for 75min and air-cooled.

[0042] Step (1): sequentially using 240#, 400#, 1000#, 2000#, 3000# and 5000# sandpaper to pre-grind the rolling surface of the above samples, and mechanically polishing with diamond polishing paste with particle size of 1.5μm; Put the sample on the micro Vickers hardness tester sample table, and set the load of 500g for 20s, as shown in Figure 1 Two indentation points A and B with a distance of 1200μm are punched on the rolled surface of the sample near the edge ab as marking points, and the center connecting line AB of the indentation points is parallel to the edge AB;

[0043] (2) to remove the surface stress layer, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com