Thermal barrier coating spraying quality evaluation and control method

A thermal barrier coating, quality technology, applied in the direction of coating, electrical program control, metal material coating process, etc., can solve the problem of inability to comprehensively and directly evaluate coating quality characteristics and process consistency, parameter hardware structure or coordination Relationship changes, no online real-time negative feedback closed-loop control, etc., to avoid the installation and debugging process of online equipment and instruments, the process layout has no effect, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

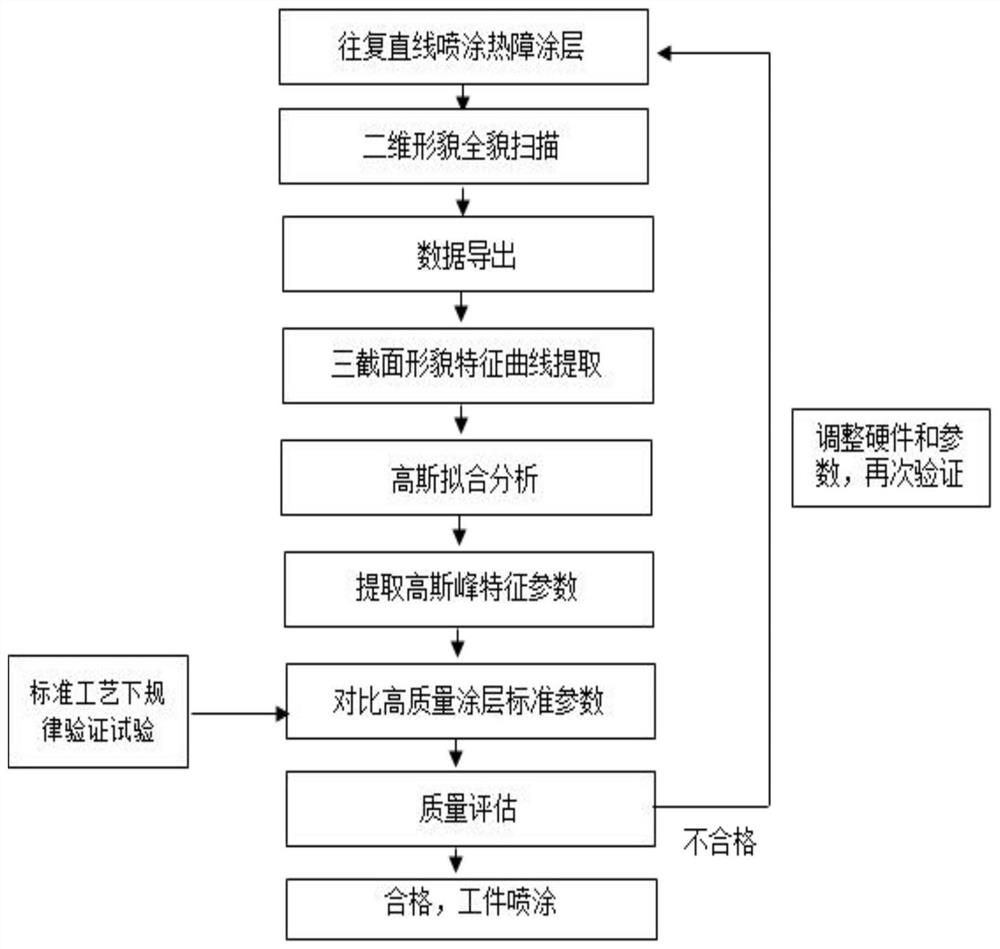

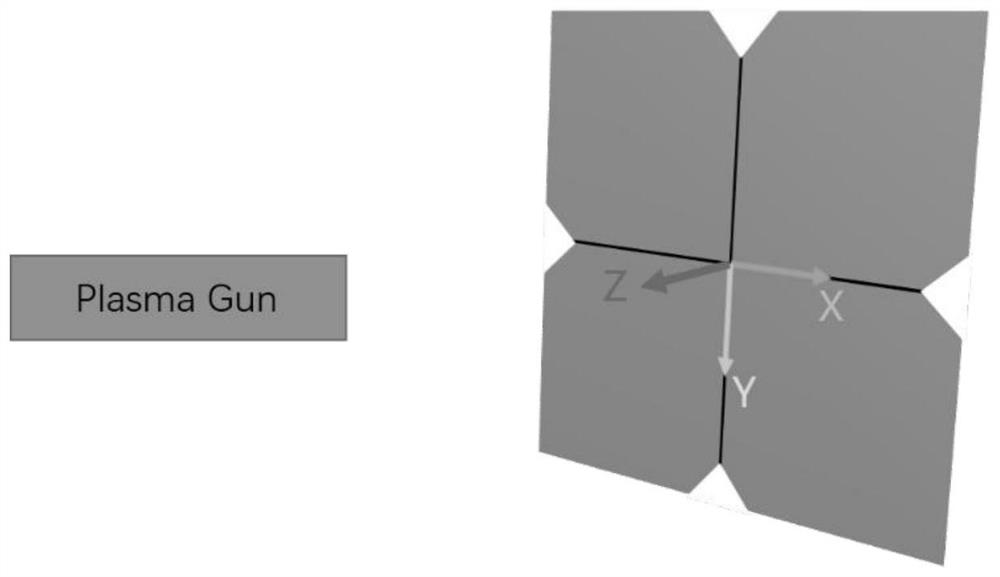

[0067] Embodiment 1: Use acetone to clean the matrix alloy, use the XP-5 suction sandblasting machine to carry out sandblasting treatment on the matrix, the abrasive is 24 mesh white corundum sand, the sandblasting pressure is 0.4MPa, and the sandblasting distance is 50-100mm, The sandblasting angle is 50-90°, and the DZ-HL5000 supersonic spraying system is used to prepare the bonding layer with a thickness of 10-30 μm. The material of the bonding layer is NiCoCrAlY powder, and the process parameters are oxygen flow rate of 20-60m 3 / h, the kerosene flow rate is 10-50L / h, the powder feeding rate is 40-80g / min, and the spraying distance is 300-400mm. After the bonding layer is prepared, use the DH-80 plasma spraying system to prepare the ceramic layer. It is 7YSZ, the process parameters are current 60-80A, voltage 550-650V, powder feeding rate 20-60g / min, spraying distance 50-100mm, spraying trajectory such as figure 2 As shown, reciprocating spraying is carried out 40 times a...

Embodiment 2

[0071] Embodiment 2: Use acetone to clean the matrix alloy, use the XP-5 suction sandblasting machine to carry out sandblasting treatment on the matrix, the abrasive is 24 mesh white corundum sand, the sandblasting pressure is 0.4MPa, and the sandblasting distance is 50-100mm, The sandblasting angle is 50-90°, use the DZ-HL5000 supersonic spraying system to prepare the bonding layer, the thickness is 10-30μm, the bonding layer material is NiCoCrAlY powder, use the DH-80 plasma spraying system to prepare the ceramic layer, the ceramic layer powder For 7YSZ, the HVOF and plasma spraying process parameters are the same as those in Implementation 1. Spray trajectory such as figure 2 As shown, reciprocating spraying is carried out 40 times along the X direction, and the moving distance of the spray gun is X 0 ±30mm, the center of the spray gun must coincide with the center line during the process, and the temperature of the spraying process should be lower than 400°C.

[0072] U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com