Process for preparing inorganic nanometer silicon-based calcium silicate heat insulation product

An inorganic nano-silicon and calcium-based calcium silicate technology, applied in ceramic products, chemical instruments and methods, mixers, etc., can solve the problem of accelerating the preparation efficiency of calcium silicate thermal insulation products, low density of calcium silicate thermal insulation products, and nano-silicon density. Low problems, to achieve the effect of stable high temperature resistance, large surface area and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

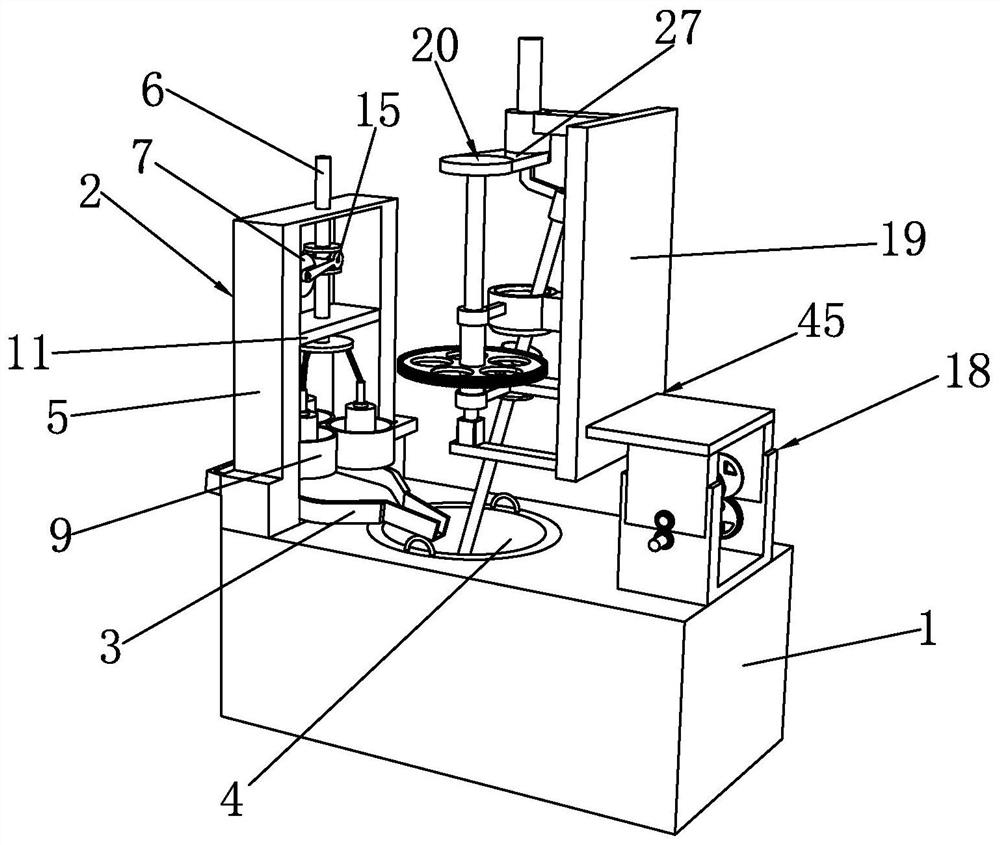

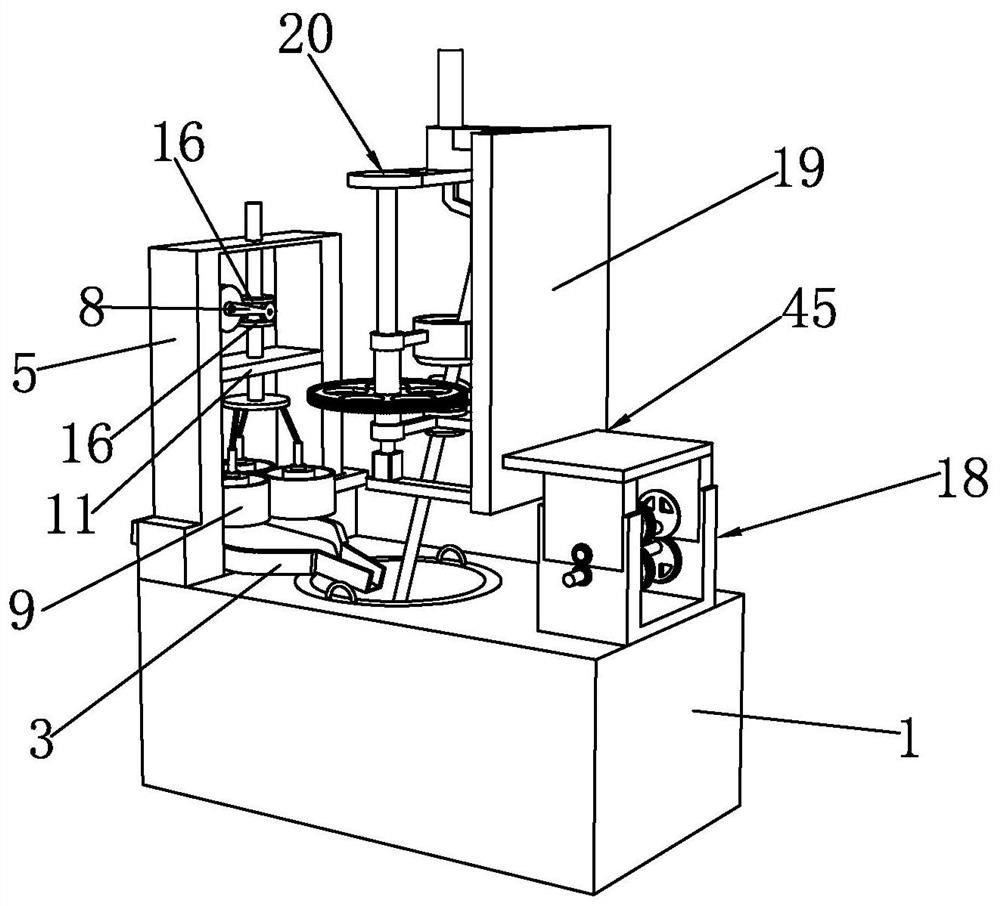

[0039] Such as Figure 1 to Figure 7 As shown, it is a process method of an inorganic nano silicon-based calcium silicate thermal insulation product of the present invention, comprising the following steps:

[0040] a. Preparation before manufacture

[0041] Firstly, nano-silicon as a nano-scale inorganic silicon material used as a reaction substrate is prepared, quicklime is used as a calcium raw material, and airgel is used as an additive.

[0042] b. Grinding and mixing

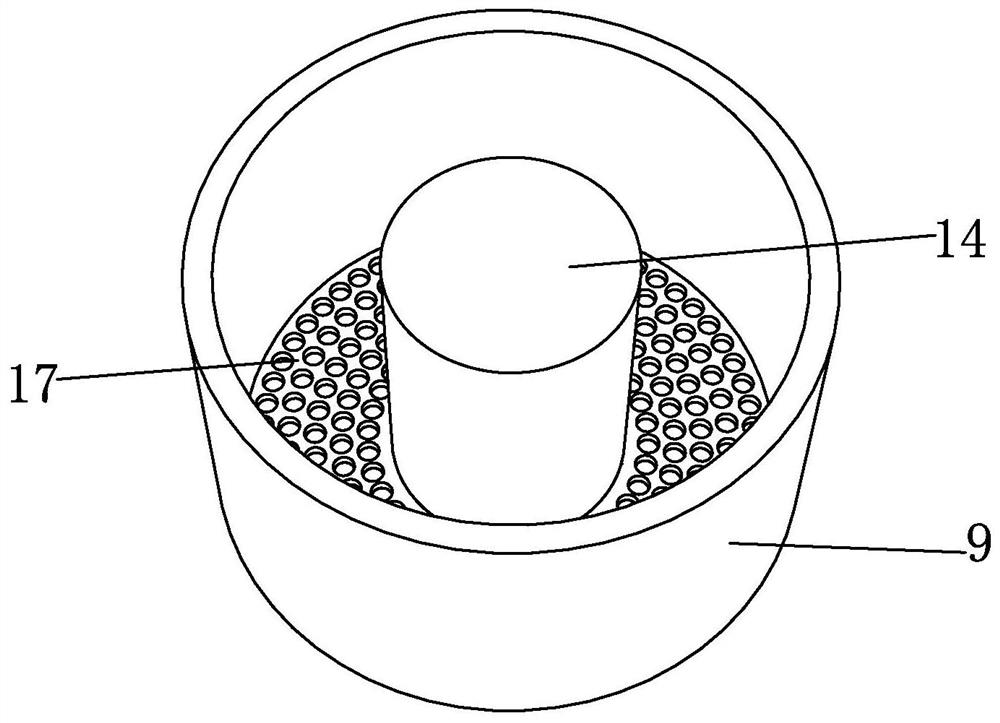

[0043] 1) Grinding: Weigh the nano-silicon, quicklime and aerogel according to the calculated mass, then put the nano-silicon, quicklime and aerogel into the grinding device located on the upper side of the processing table 1 at the same time, and the grinding device is simultaneously Nano-silicon, quicklime and airgel are ground and pulverized to produce nano-silicon powder, quicklime powder and airgel powder.

[0044] 2) Mixing: Nano-silicon powder, quicklime powder and airgel powder automatically fal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com