BiFe1-xCuxO3 perovskite material and preparation method

A perovskite material, a certain amount of technology, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve the poor mobility of photogenerated carriers , slow circulation rate and other problems, to achieve the effect of ensuring water quality safety, efficient activation, uniform particle size and morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

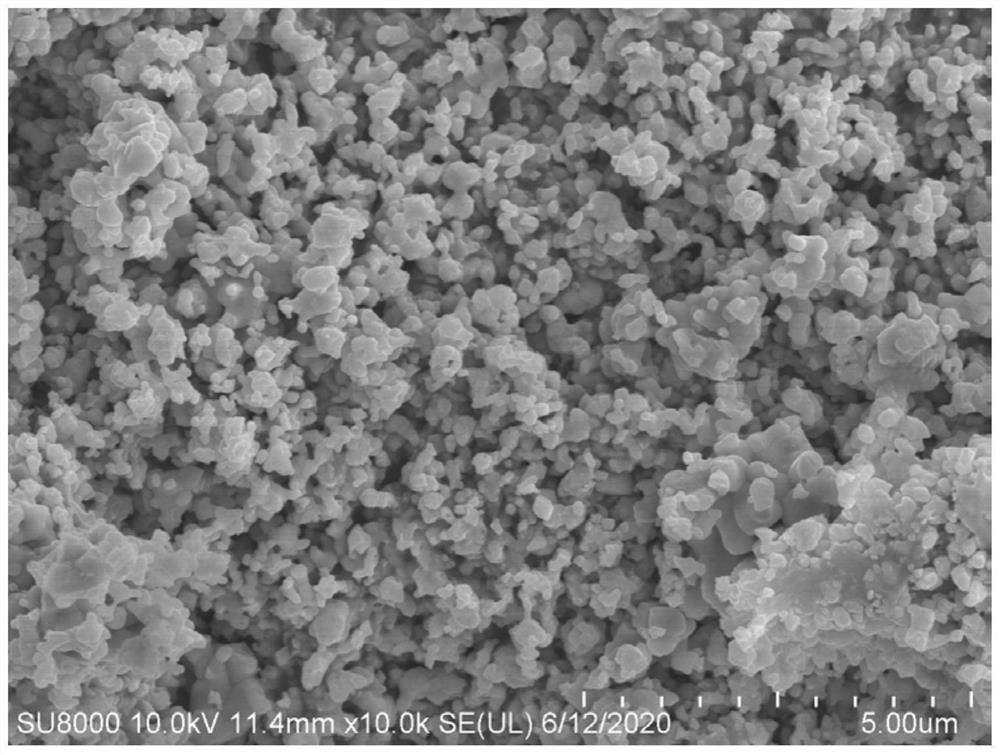

[0040] Step 1, according to the molar concentration ratio is 1:0.95:0.05, weigh Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O and Cu(NO 3 ) 2 ·3H 2 O, dissolved in ethylene glycol so that the total concentration of metal ions is 0.02mol / L, and stirred in a water bath at 30°C for 2 hours to obtain a reddish-brown sol;

[0041] Step 2, place it in an oven for 24 hours to dry it, and the drying temperature is 70°C;

[0042] Step 3: Place the material in a muffle furnace for pre-calcination at 300°C for 1 hour, and then calcinate at 550°C for 1 hour to obtain catalyst powder. The heating rate of the muffle furnace is 4°C / min;

[0043] Step 4, grinding the calcined material to uniform fine particles for later use.

Embodiment 2

[0045] Step 1, according to the molar concentration ratio is 1:0.92:0.08, weigh Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O and Cu(NO 3 ) 2 ·3H 2 O, dissolved in ethylene glycol so that the total concentration of metal ions is 0.02mol / L, and stirred in a water bath at 30°C for 2 hours to obtain a reddish-brown sol;

[0046] Step 2, place it in an oven for 24 hours to dry it, and the drying temperature is 70°C;

[0047] Step 3: Place the material in a muffle furnace for pre-calcination at 300°C for 1 hour, and then calcinate at 550°C for 1 hour to obtain catalyst powder. The heating rate of the muffle furnace is 4°C / min;

[0048] Step 4, grinding the calcined material to uniform fine particles for later use.

Embodiment 3

[0050] Step 1, according to the molar concentration ratio of 1:0.9:0.1, weigh Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O and Cu(NO 3 ) 2 ·3H 2 O, dissolved in ethylene glycol so that the total concentration of metal ions is 0.02mol / L, and stirred in a water bath at 30°C for 2 hours to obtain a reddish-brown sol;

[0051] Step 2, place it in an oven for 24 hours to dry it, and the drying temperature is 70°C;

[0052] Step 3: Place the material in a muffle furnace for pre-calcination at 300°C for 1 hour, and then calcinate at 550°C for 1 hour to obtain catalyst powder. The heating rate of the muffle furnace is 4°C / min;

[0053] Step 4, grinding the calcined material to uniform fine particles for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com