Copper metaaluminate memristor based on flexible substrate and preparation method

A flexible substrate and memristor technology, applied in the direction of electrical components, etc., to achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

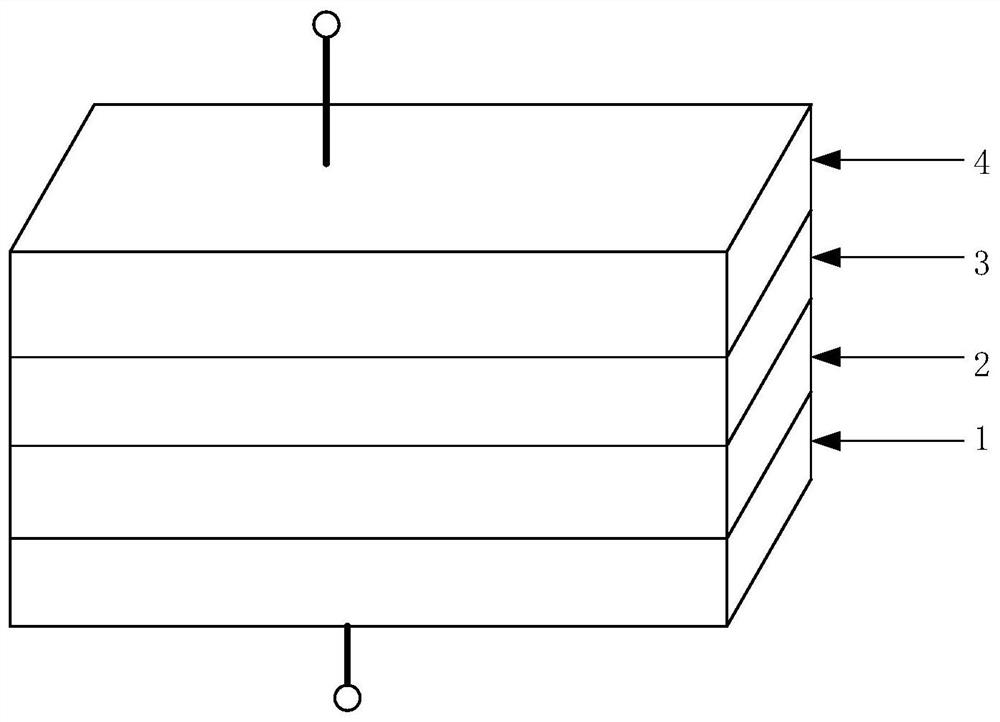

[0031] This embodiment provides a copper metaaluminate memristor based on a flexible substrate, the memristor has a vertical four-layer structure of an upper electrode 4, a resistive layer 3, a lower electrode 2, and a flexible substrate 1 from top to bottom. The upper electrode 4 of the memristor is a copper film; the resistive layer 3 of the memristor device is a copper metaaluminate film; the lower electrode 2 is a transparent conductive film of indium tin oxide; the flexible substrate of the memristor 1 is polyethylene naphthalate.

[0032] The resistive layer 3 of the memristor is obtained by radio frequency sputtering, and has a thickness of 50nm-300nm.

[0033] The bottom electrode 2 is an indium tin oxide bottom electrode with a thickness of 100-200 nm.

[0034] This embodiment also provides a method for preparing a copper metaaluminate memristor based on a flexible substrate, including the following process steps:

[0035] (1) Prepare polyethylene naphthalate as a f...

Embodiment 2

[0049] This embodiment provides a copper metaaluminate memristor based on a flexible substrate, the memristor has a vertical four-layer structure of an upper electrode 4, a resistive layer 3, a lower electrode 2, and a flexible substrate 1 from top to bottom. The upper electrode 4 of the memristor is a copper film or a silver film; the resistive layer 3 of the memristor is a copper metaaluminate film; the lower electrode 2 is a transparent conductive film of indium tin oxide; the memristor The flexible substrate 1 is polyethylene terephthalate material.

[0050] The resistive layer 3 of the memristor is obtained by radio frequency sputtering, and has a thickness of 50nm-300nm.

[0051] The upper electrode 4 of the memristor is a copper film.

[0052] The bottom electrode 2 is an indium tin oxide bottom electrode with a thickness of 100-200 nm.

[0053] This embodiment also provides a method for preparing a copper metaaluminate memristor based on a flexible substrate, including...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com