A magnesium-based alloy wire with controllable degradation and its preparation method

A magnesium-based alloy and magnesium alloy technology are applied in the field of magnesium-based alloy wire and its preparation, which can solve the problems of outer layer shedding, stress concentration, and reduce the mechanical properties of magnesium alloy wire, and achieve high strength and good deformation coordination. , the effect of broadening the scope of industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

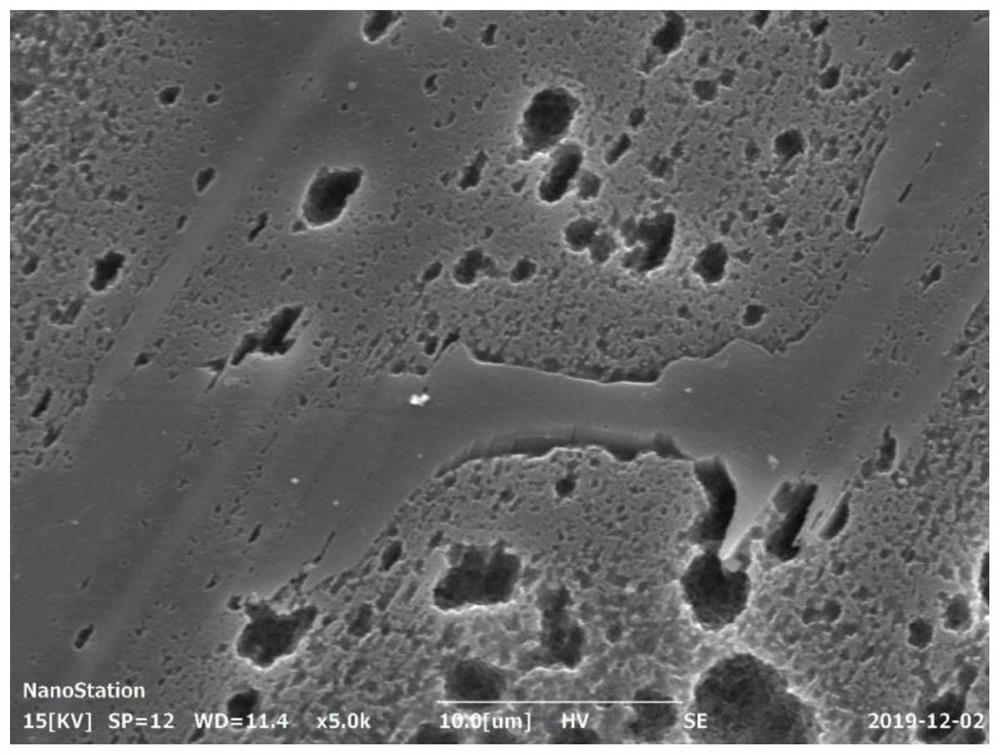

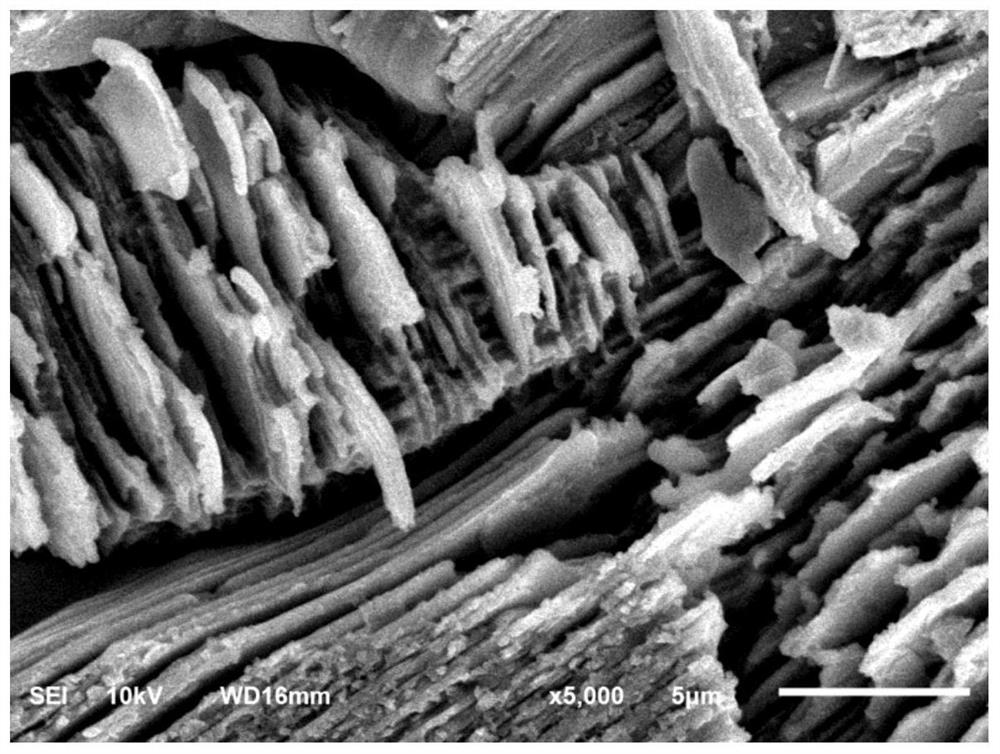

Image

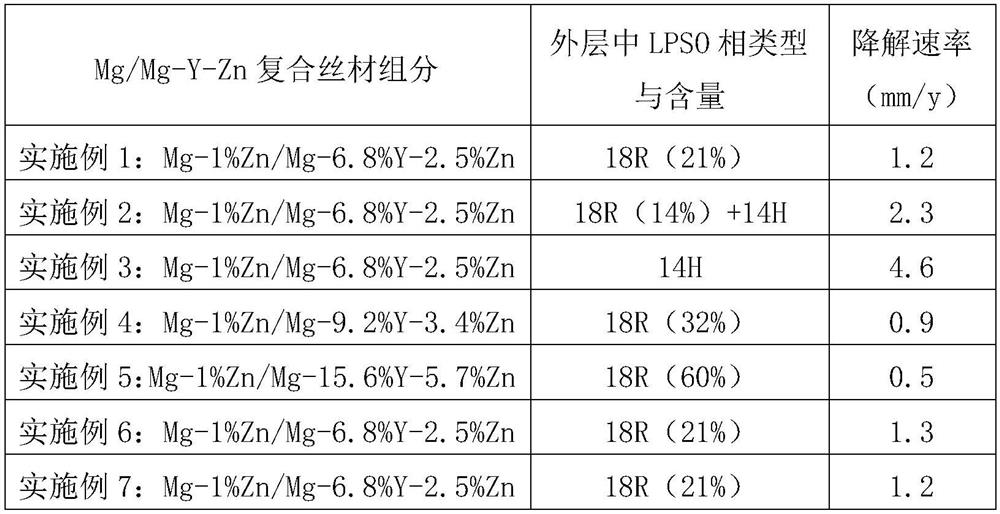

Examples

Embodiment 1

[0024] Prepare Mg-1%Zn / Mg-6.8%Y-2.5%Zn composite material filament (mass percentage), its preparation method is as follows:

[0025] (1) Ingredients: weighing according to the ingredients of the above components;

[0026] (2) Mold making: Cut out a Mg-1%Zn alloy rod with a diameter of 4.5mm. The alloy rod is an alloy rod purchased on the market. After surface grinding and polishing, it is placed in the center of a cylindrical mold with an inner diameter of 5mm. ;

[0027] (3) Composite casting: pure zinc ingot, pure magnesium ingot and magnesium yttrium master alloy ingot in CO 2 and SF 6 Smelting under the protection of a mixed atmosphere to prepare Mg-Y-Zn molten alloy liquid, and then cast it in a cylindrical mold with Mg-1%Zn alloy rods; after casting, control the cylindrical mold to keep warm at 300 ° C for 30 minutes, and then cool naturally Remove the film at room temperature to obtain a magnesium alloy composite rod;

[0028] (4) Heat treatment: keep the magnesium ...

Embodiment 2

[0032] Prepare Mg-1%Zn / Mg-6.8%Y-2.5%Zn composite material filament (mass percentage), its preparation method is as follows:

[0033] (1) Ingredients: weighing according to the ingredients of the above components;

[0034] (2) mold making: cut out the Mg-1%Zn alloy rod that diameter is 4.5mm, be placed in the center of the cylinder mold that mold cavity inner diameter is 5mm after surface grinding and polishing;

[0035] (3) Composite casting: Melting pure zinc ingots, pure magnesium ingots and magnesium-yttrium intermediate alloy ingots under vacuum to prepare Mg-Y-Zn molten alloy liquid, and then casting it on a cylinder with Mg-1%Zn alloy rods placed In the body mold; after casting, the cylinder mold is controlled to keep warm at 300°C for 30min, and then naturally cooled to room temperature to release the film to obtain a magnesium alloy composite rod;

[0036] (4) Heat treatment: keep the magnesium alloy composite bar after stripping at 350°C for 1 hour, and then cool it ...

Embodiment 3

[0040] Prepare Mg-1%Zn / Mg-6.8%Y-2.5%Zn composite material filament (mass percentage), its preparation method is as follows:

[0041] (1) Ingredients: weighing according to the ingredients of the above components;

[0042] (2) mold making: cut out the Mg-1%Zn alloy rod that diameter is 4.5mm, be placed in the center of the cylinder mold that mold cavity inner diameter is 5mm after surface grinding and polishing;

[0043] (3) Composite casting: Melting pure zinc ingots, pure magnesium ingots and magnesium-yttrium intermediate alloy ingots under vacuum to prepare Mg-Y-Zn molten alloy liquid, and then casting it on a cylinder with Mg-1%Zn alloy rods placed In the body mold; after casting, the cylinder mold is controlled to keep warm at 300°C for 30min, and then naturally cooled to room temperature to release the film to obtain a magnesium alloy composite rod;

[0044] (4) Heat treatment: keep the magnesium alloy composite bar after stripping at 350°C for 4 hours, and then cool it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com