Enhanced calcium phosphate bone repair material and preparation method thereof

A repair material, calcium phosphate technology, applied in the field of medical biomaterials, can solve the problems of slow degradation, poor mechanical properties, low strength, etc., and achieve the effect of improved mechanical properties, significant mechanical properties, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

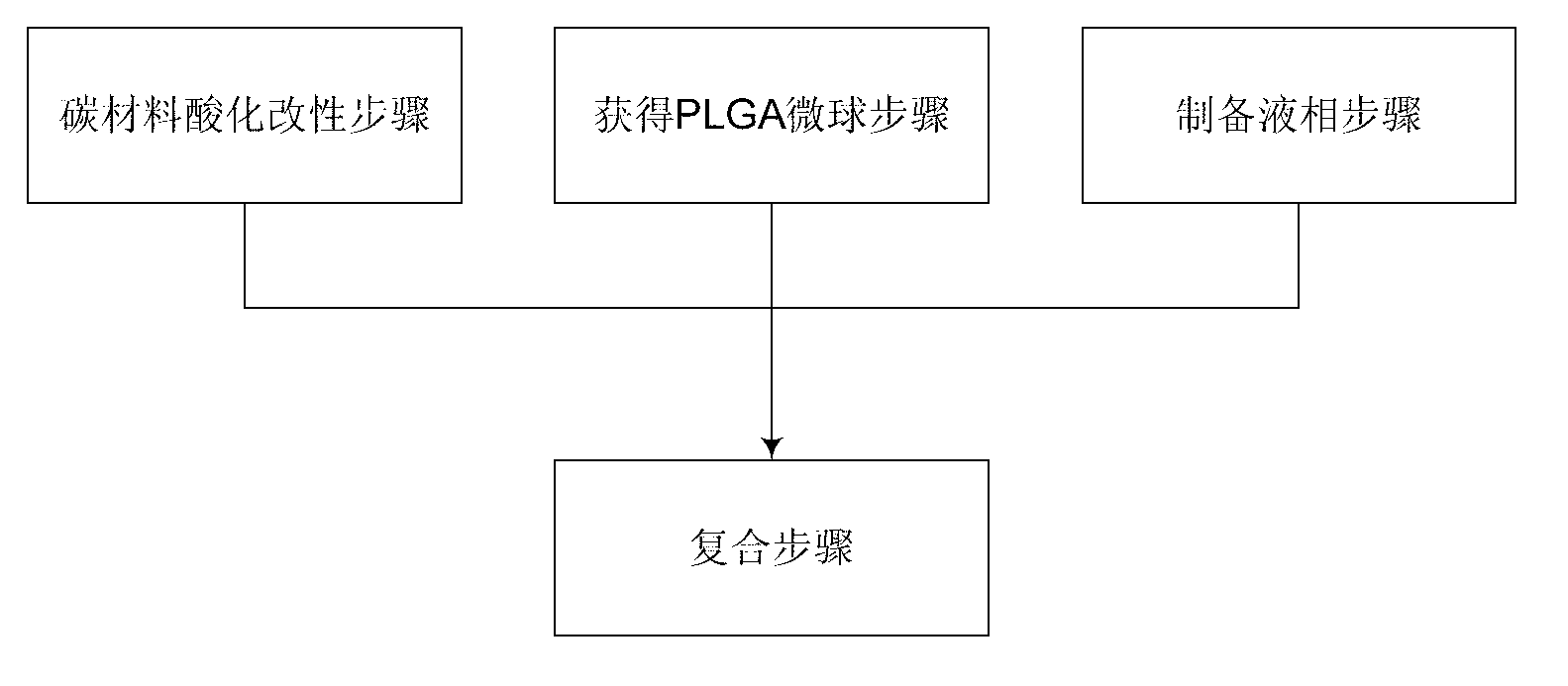

[0033] On the other hand, the present invention also provides a method for preparing the above-mentioned enhanced calcium phosphate bone repair material, comprising the following steps:

[0034] 1. Acidification modification steps of carbon materials

[0035] Put the selected carbon material (carbon nanotube or graphene) into the container, and pour the mixed acid mixed by nitric acid and sulfuric acid, the mixed acid is preferably made of nitric acid and sulfuric acid according to the ratio of nitric acid: sulfuric acid = 1:3 The volume ratio is mixed, and then ultrasonic treatment is performed for 0.5-1.5h, and then the reflux reaction is carried out at a temperature of 50-100°C and magnetic stirring, and the heating rate is controlled at 10-25°C / min, and the reaction is about 8 hours later. After the reaction is complete, rinse the product with deionized water until the pH is 7, and after standing for 24 hours, centrifuge at 5000-10000 rpm to separate the acid-treated carbo...

Embodiment 1

[0050] 1. Acidification modification of carbon nanotubes

[0051] According to the volume ratio of nitric acid: sulfuric acid = 1:3, mix nitric acid and sulfuric acid to prepare mixed acid, put 100mg of carbon nanotubes into a 250ml three-neck bottle and then pour the mixed acid, and then place the mixture of carbon nanotubes and mixed acid solution in an ultrasonic Sonicate in the machine for 0.8h, then start the reflux reaction at a temperature of 100°C and magnetic stirring, control the heating rate at 10°C / min, and the reaction time is 8 hours. After the reaction is completed, wash the product with deionized water until the pH is 7, let it stand for 24 hours, and then centrifuge at 5000rpm to separate the acid-treated carbon nanotubes, and place them in a vacuum oven for drying at 60°C. The resulting product is carboxylated carbon nanotubes. Tube.

[0052] 2. Preparation of PLGA microspheres

[0053] Take 0.2g of PLGA solid and add it to 2ml of DCM solution, emulsify wit...

Embodiment 2

[0060] 1. Acidification modification of carbon nanotubes

[0061] The specific implementation process is the same as the carbon nanotube acidification modification process in Example 1.

[0062] 2. Preparation of PLGA microspheres

[0063] The specific implementation process is the same as the preparation process of the PLGA microspheres in Example 1.

[0064] 3. Preparation of liquid phase solution

[0065] Physiological saline with a concentration of 0.15mol / ml was prepared as a liquid phase solution.

[0066] 4. Composite

[0067] (1) Add 6 mg of acidified modified carbon nanotubes to 5 mL of normal saline, ultrasonicate for 15 minutes, and then mix polybasic calcium phosphate and PLGA microspheres in a mass ratio of 4:0.5 to obtain a solid-phase mixture; the polybasic phosphoric acid The calcium salt is composed of DCPA, TTCP, HA, β-TCP, OCP and ACP, and the mass percentage ranges of each component are: 5-15%, 35-50%, 5-20%, 32%-40%, 5-10% and 1-8%;

[0068] (2) Mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com