Novel nano-modified high-strength concrete

A nano-modification and concrete technology, applied in the field of concrete, can solve the problems of affecting the range of use of concrete, affecting the performance of concrete, and reducing the remaining properties of concrete, so as to improve particle gradation and compactness, increase mechanical properties, and resist salt and frost. Effect of performance and high temperature resistance retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

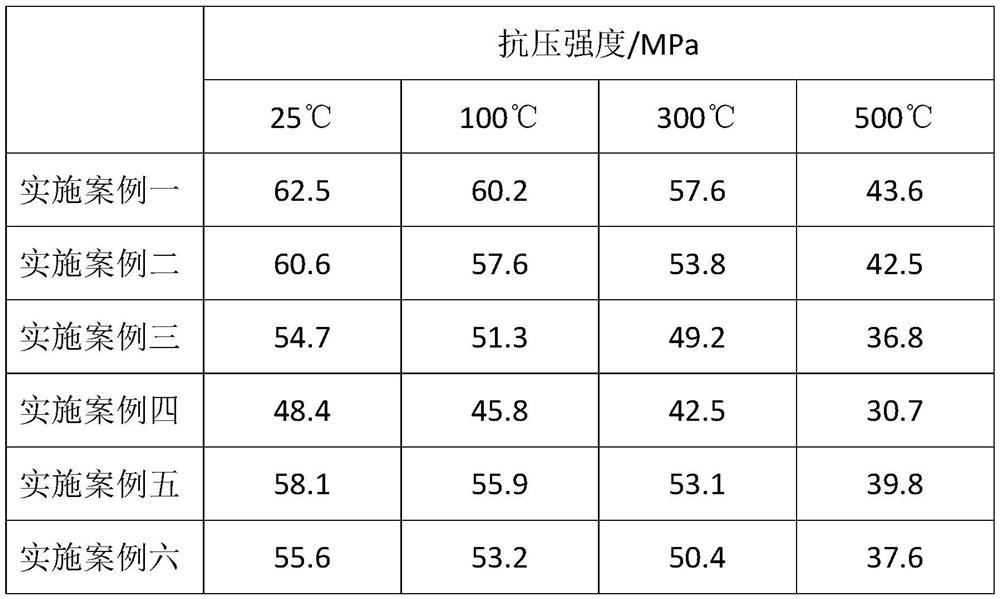

Examples

Embodiment example 1

[0036] A novel nano-modified high-strength concrete, comprising the following components by mass fraction: The nano-modified high-strength concrete comprises the following components by mass fraction: 180 parts of water, 340 parts of Portland cement, aggregate 650 parts, 19 parts of nano silicon oxide, 230 parts of nano carbon fiber, 56 parts of silica fume, 72 parts of mineral powder, 3 parts of sodium lignosulfonate, 22 parts of quartz powder.

[0037] Including the following preparation methods:

[0038] 1) Weigh each raw material component according to the stated ratio;

[0039] 2) Add Portland cement, aggregate, silica fume and mineral powder into the mixer according to the weight ratio, and stir the mixer for 5 minutes;

[0040] 3) Dissolving sodium lignosulfonate into water, ultrasonically dispersing the nano-silicon oxide and nano-carbon fiber for 30 minutes respectively, and then adding into the water dissolved with sodium lignosulfonate;

[0041] 4) Add the water c...

Embodiment example 2

[0045] A novel nano-modified high-strength concrete, comprising the following components by mass fraction: The nano-modified high-strength concrete comprises the following components by mass fraction: 170 parts of water, 340 parts of Portland cement, aggregate 620 parts, 19 parts of nano-iron oxide, 230 parts of nano-carbon fiber, 52 parts of silica fume, 67 parts of mineral powder, 3 parts of sodium sulfite, and 22 parts of silicon nitride.

[0046] Including the following preparation methods:

[0047] 1) Weigh each raw material component according to the stated ratio;

[0048] 2) Add Portland cement, aggregate, silica fume and mineral powder into the mixer according to the weight ratio, and stir the mixer for 5 minutes;

[0049] 3) Dissolve sodium sulfite into water, ultrasonically disperse nano-iron oxide and nano-carbon fiber for 30 minutes respectively, and then add into water dissolved with sodium sulfite;

[0050] 4) Add water containing sodium sulfite, nano-iron oxid...

Embodiment example 3

[0054] A novel nano-modified high-strength concrete, comprising the following components by mass fraction: The nano-modified high-strength concrete comprises the following components by mass fraction: 200 parts of water, 400 parts of Portland cement, aggregate 650 parts, 13 parts of nano silicon oxide, 230 parts of nano carbon fiber, 60 parts of silica fume, 75 parts of mineral powder, 4 parts of sodium lignosulfonate, 25 parts of quartz powder.

[0055] Including the following preparation methods:

[0056] 1) Weigh each raw material component according to the stated ratio;

[0057] 2) Add Portland cement, aggregate, silica fume and mineral powder into the mixer according to the weight ratio, and stir the mixer for 5 minutes;

[0058] 3) Dissolving sodium lignosulfonate into water, ultrasonically dispersing the nano-silicon oxide and nano-carbon fiber for 30 minutes respectively, and then adding into the water dissolved with sodium lignosulfonate;

[0059] 4) Add the water c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com