CPVC pipe and preparation method thereof

A technology of CPVC resin and PVC resin, applied in the field of CPVC pipe and its preparation, can solve the problems of poor thermal stability, decreased impact performance of materials, limited expansion of application fields, etc., and achieves low cost, simple processing, and regular shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1, a kind of preparation method of PVC resin comprises the following steps:

[0044] Test equipment and raw materials: 4m 3 Polymerization kettle, two layers of three-blade back-swept stirring, two baffles. Vinyl chloride monomer, purity≧99.98%, initiator 1 is 75% (m / m) diethylhexyl peroxydicarbonate organic solution, purchased from Tianjin Aksu Chemical Company, initiator 2 is 75% (m / m) m) organic solution of cumyl peroxide neodecanoate, purchased from Tianjin Aksu Chemical Company, dispersant 1 is 6.0% (m / m) polyvinyl alcohol KH-20 aqueous solution, purchased from Japan Synthetic Chemical Company, dispersing Agent 2 is 15% (m / m) dioctyl adipate methanol solution, purchased from Nantong Runfeng Petrochemical Co., Ltd. The terminator is 40% (m / m) acetone thiosemicarbazone aqueous solution, purchased from Hubei Ferry Chemical Co., Ltd.

[0045] Add 1700L of deionized water, 680g of initiator 1, 195g of initiator 2, 5.1kg of dispersant 1, and 1.02kg of dispersant 2 int...

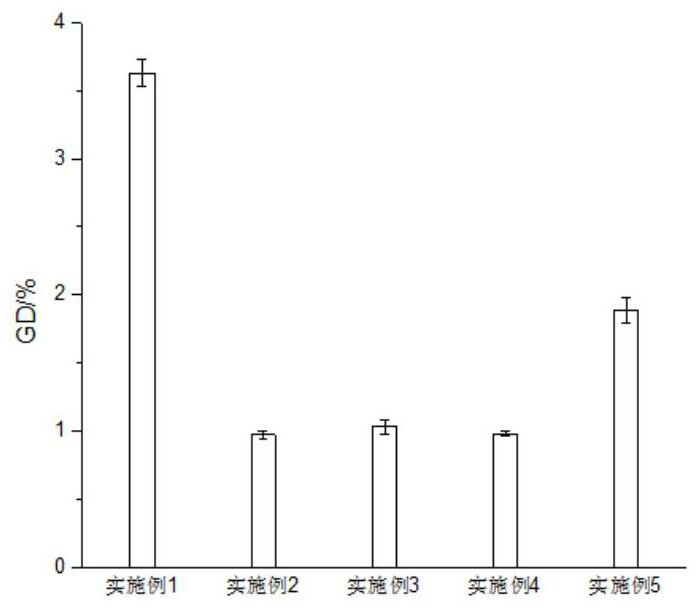

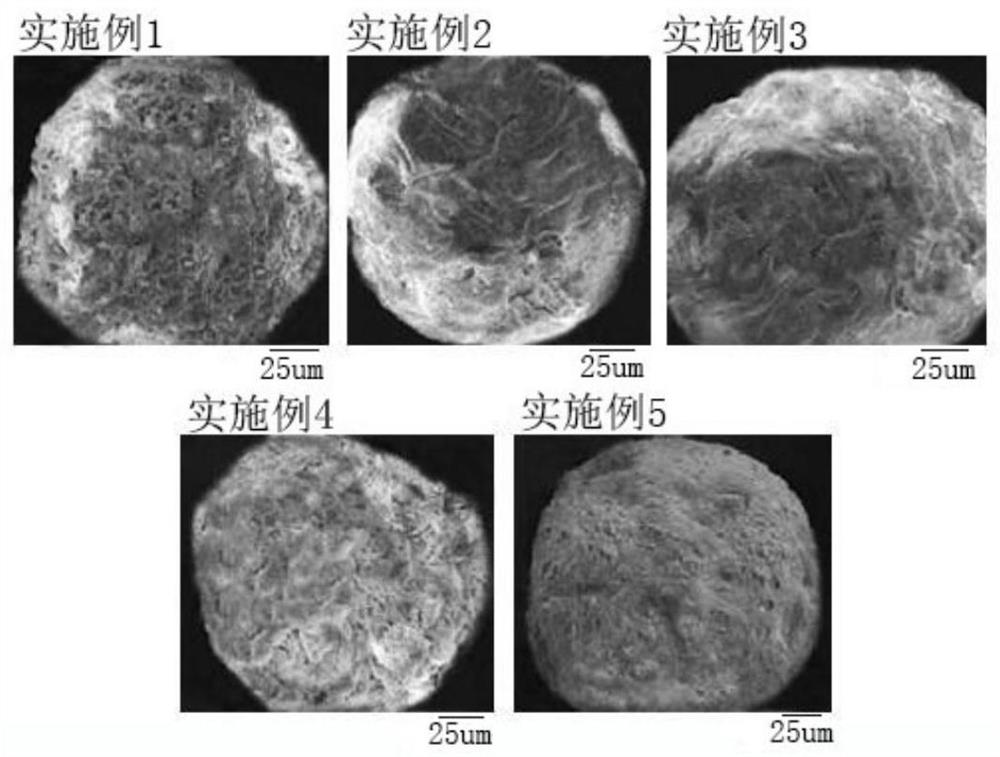

Embodiment 2

[0055] The addition amount of dispersant 1 is 6.12kg, and the addition amount of dispersant 2 is 0.613kg. All the other parts are completely consistent with Example 1.

Embodiment 3

[0057] The addition amount of dispersant 1 is 2.55kg, and the addition amount of dispersant 2 is 2.04kg. All the other parts are completely consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com