PHC tubular pile non-autoclaved concrete active powder and preparation method thereof

A PHC pipe pile and concrete technology, applied in the field of pipe pile concrete, can solve problems such as unreasonable formula, poor concrete fluidity, and impact resistance, achieving significant economic and social benefits, reducing CO2 emissions, and promoting cement water. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

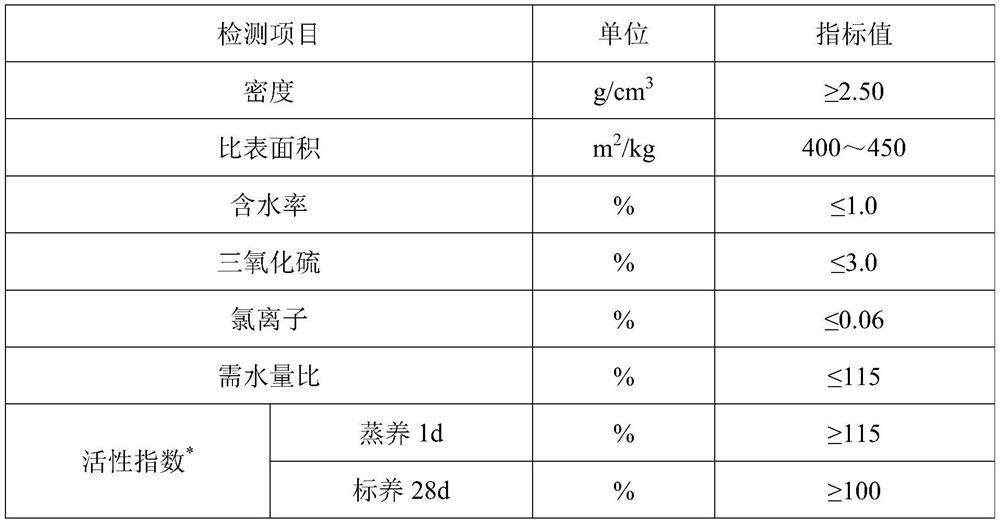

[0024] A kind of PHC pipe pile non-autoclaved concrete active powder, containing 35% granulated blast furnace slag powder, 20% fly ash, 5% silica fume, 10% microbeads, 5% gypsum powder, 20% nickel slag powder, early strength agent 5%.

[0025] Among them, the specific surface area of nickel slag powder is not less than 400m 2 / kg, by mass, the amorphous content is not less than 35%, SiO 2 、Al 2 o 3 And CaO content is not less than 50%, MgO content is less than 25%, SiO 2 / MgO is greater than 1.8; gypsum powder includes anhydrous gypsum and dihydrate gypsum, according to the mass ratio, anhydrous gypsum:dihydrate gypsum is 8:2, and gypsum powder is β-CaSO 4 and α-CaSO 4 0.5H 2 O; early strength agent is CSH crystal nucleus.

[0026] The preparation method of the above-mentioned PHC pipe pile non-autoclaved concrete active powder is:

[0027] Step 1: Measure 35% of granulated blast furnace slag powder, 20% of fly ash, and 10% of nickel slag powder respectively and put ...

Embodiment 2

[0050] A kind of PHC pipe pile non-autoclaved concrete active powder, including granulated blast furnace slag powder 49%, fly ash 20%, silica fume 5%, microbeads 8.9%, gypsum powder 7%, nickel slag powder 10%, early strength Agent 0.1%.

[0051] Among them, the specific surface area of nickel slag powder is not less than 400m 2 / kg, by mass, the amorphous content is not less than 35%, SiO 2 、Al 2 o 3 And CaO content is not less than 50%, MgO content is less than 25%, SiO 2 / MgO is greater than 1.8; gypsum powder includes anhydrous gypsum and dihydrate gypsum, according to the mass ratio, anhydrous gypsum:dihydrate gypsum is 8:2, and gypsum powder is β-CaSO 4 and α-CaSO 4 0.5H 2 O; the early strengthening agent is calcium formate.

[0052] The preparation method of the above-mentioned PHC pipe pile non-autoclaved concrete active powder comprises the following steps:

[0053] Step 1: Measure 49% of granulated blast furnace slag powder, 20% of fly ash, and 10% of nickel...

Embodiment 3

[0064] A kind of PHC pipe pile non-autoclaved concrete active powder, containing 40% of granulated blast furnace slag powder, 20% of fly ash, 5% of silica fume, 15% of microbeads, 8% of gypsum powder, 10% of nickel slag powder, and early strength agent 2%.

[0065] Among them, the specific surface area of nickel slag powder is not less than 400m 2 / kg, by mass, the amorphous content is not less than 35%, SiO 2 、Al 2 o 3 And CaO content is not less than 50%, MgO content is less than 25%, SiO 2 / MgO is greater than 1.8; gypsum powder includes anhydrous gypsum and dihydrate gypsum, according to the mass ratio, anhydrous gypsum:dihydrate gypsum is 8:2, and gypsum powder is β-CaSO 4 and α-CaSO 4 0.5H 2 O; the early strength agent is made of Fe 2 SO 4 , calcium formate, and CSH crystal nucleus, and its mass ratio is Fe 2 SO 4 : Calcium formate: CSH crystal nucleus = 1:2:7.

[0066] A preparation method of PHC pipe pile non-autoclaved concrete active powder, comprising t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com