A controllable preparation method of high-density single-walled carbon nanotube horizontal arrays

A single-walled carbon nanotube, high-density technology, applied in the field of nanomaterials, can solve the problems of low horizontal array density of single-walled carbon nanotubes, uneven quality of finished products, no controllable preparation method, etc. The effect of good quality and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A controllable preparation method of a high-density single-walled carbon nanotube horizontal array of the present invention comprises the following steps:

[0053] Step 1, processing the growth substrate, and loading a catalyst on the processed growth substrate;

[0054] Processing the growth substrate includes the following steps:

[0055] S1, in order to clean the ST-cut quartz substrate and repair the lattice defects generated during the production and processing of the growth substrate, the growth substrate was ultrasonically cleaned in ultrapure water, acetone, ethanol, and ultrapure water in sequence, and the cleaning time was controlled 10min in each cleaning solution;

[0056] Wherein, the growth substrate is one of ST-cut quartz, r-cut quartz, a-plane α-alumina, r-plane α-alumina and magnesium oxide. ST-cut quartz substrates are preferred. The type of catalyst precursor is Fe or Co or Ni or Ru or Rh or Pd, and the particle size of the catalyst is 1 nm-3 nm. ...

Embodiment 2

[0074] Embodiment 2, a controllable preparation method of a high-density single-walled carbon nanotube horizontal array, is the same as Embodiment 1, except that:

[0075] Fe(OH) used 3 / EtOH solution was replaced by NiCl 2 NiCl at a concentration of 0.05 mmol / L 2 / EtOH solution, it was drawn on the ST-cut quartz substrate, that is, the Ni-containing catalyst was loaded on the surface of the ST-cut quartz substrate.

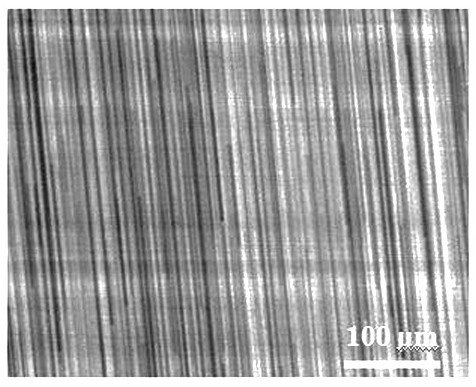

[0076] The growth result of the horizontal array of high-density single-walled carbon nanotubes obtained in Example 2 is as follows Figure 2d shown. It can be seen from the figure that the SEM picture clearly shows that the density of the horizontal array of single-walled carbon nanotubes obtained in this embodiment exceeds 50 / micron.

[0077] The invention also provides a field effect transistor device containing a horizontal array of high-density single-walled carbon nanotubes.

[0078] The invention also provides the application of the horizontal array ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com