Method for preventing rare earth steel continuous casting nozzle from being blocked

A continuous casting nozzle and rare earth technology, which is applied in casting equipment, casting melt containers, manufacturing tools, etc., to reduce labor pressure and cost, ensure high purity, and solve the effect of nozzle blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

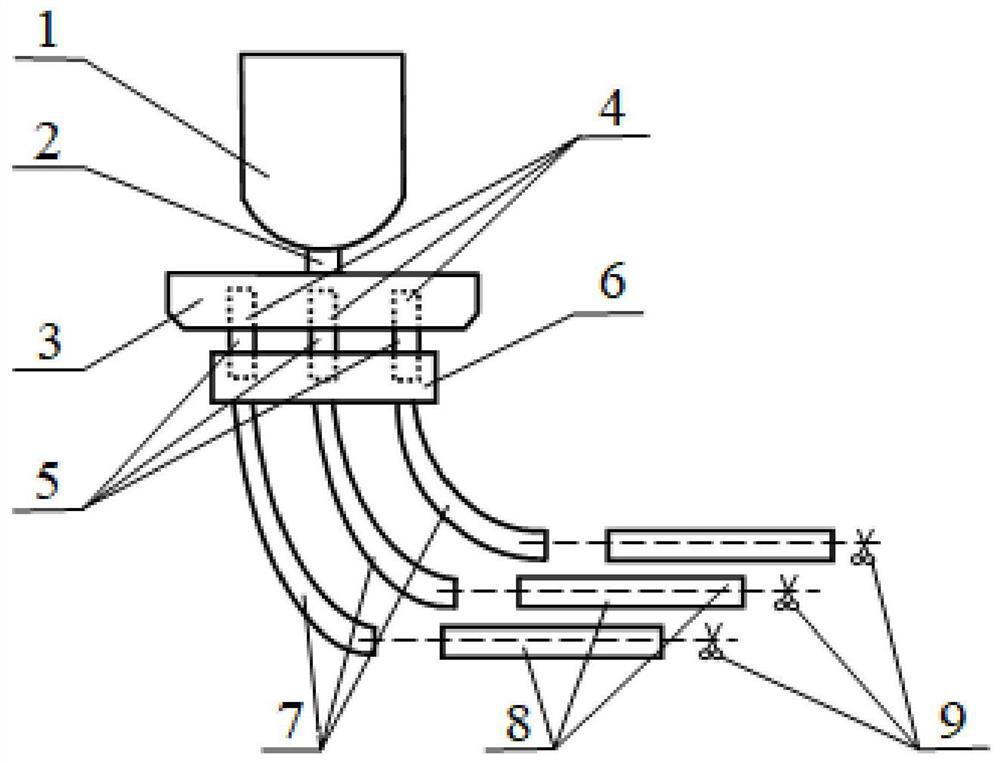

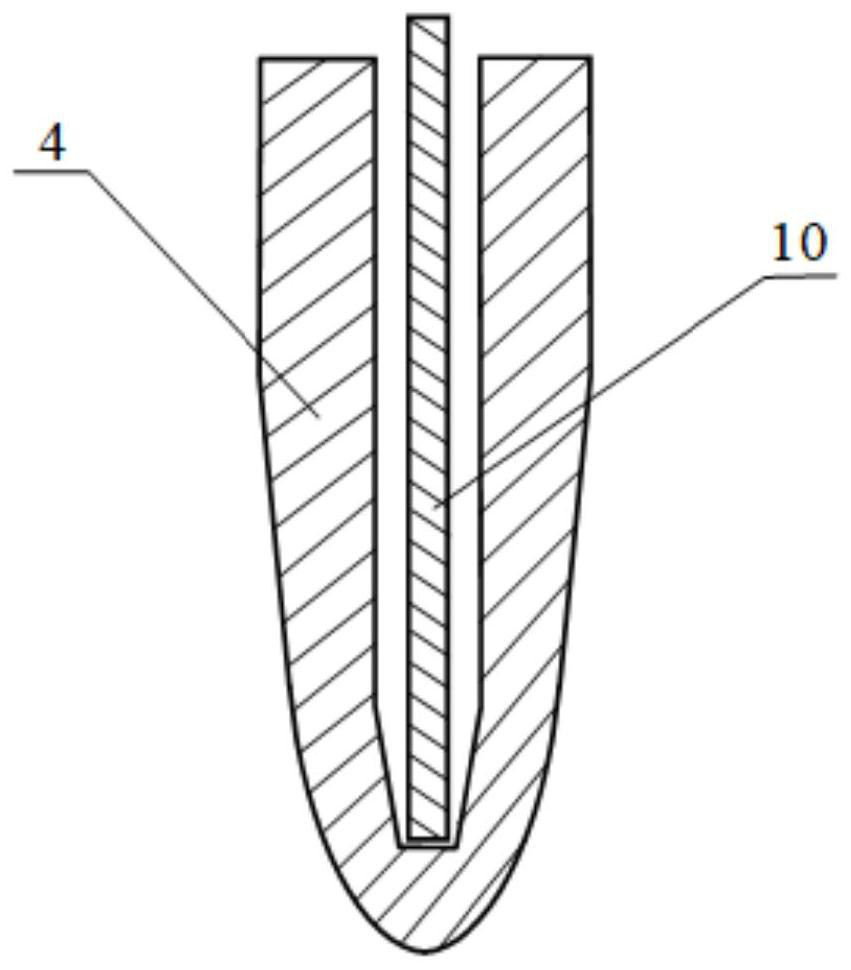

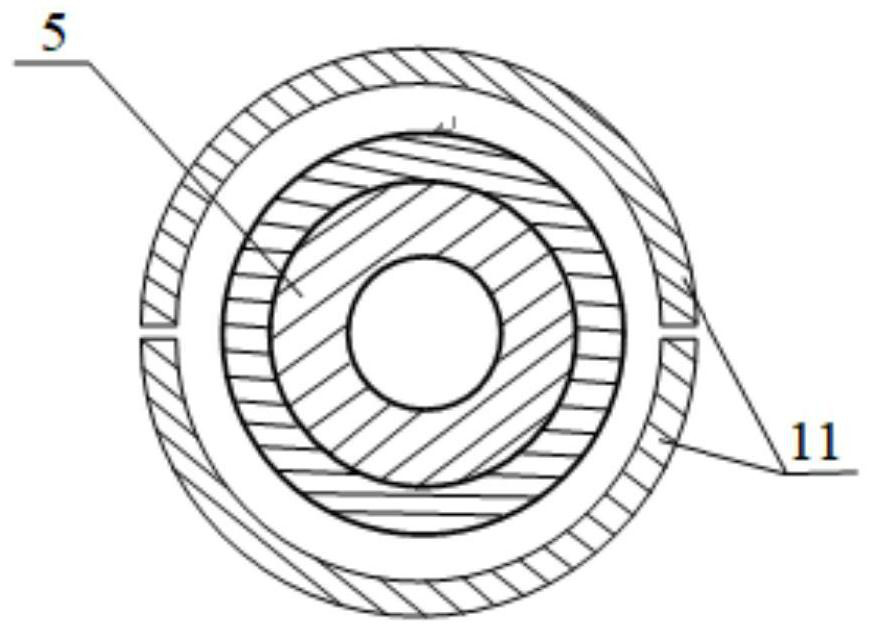

[0030] Such as Figure 1-3 As shown, the device used in the embodiment of the present invention to prevent the clogging of the rare earth steel continuous casting nozzle includes a heating rod 10 and a heating cylinder 11; the heating rod 10 is placed at the center of the stopper rod 4, and the stopper rod 4 is placed in the tundish 3, the tundish 3 is connected to the crystallizer 6 through the submerged nozzle 5, and the outside of the submerged nozzle 5 is covered by the heating cylinder 11, which is composed of two semicircular heating cylinders spliced together. The diameter of the heating rod 10 is 30-60 mm, and both the heating rod 10 and the heating cylinder 11 are electric heating elements of molybdenum disilicide.

[0031] A method for preventing the clogging of the rare earth steel continuous casting nozzle described in the embodiment of the present invention is smelted in a 50 t electric furnace to produce the rare earth bearing steel GCr15Re as an example. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com