Preparation method of cosmetic raw material peony flower extracting solution with high oxidation resistance

A peony flower, oxidative technology, applied in the field of preparation of peony flower extract, which is a raw material for cosmetics, can solve the problems of unsuitable long-distance transportation and storage, high energy consumption of the process method, low antioxidant activity, etc., and achieve long storage time and anti-freeze Strong base capacity and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

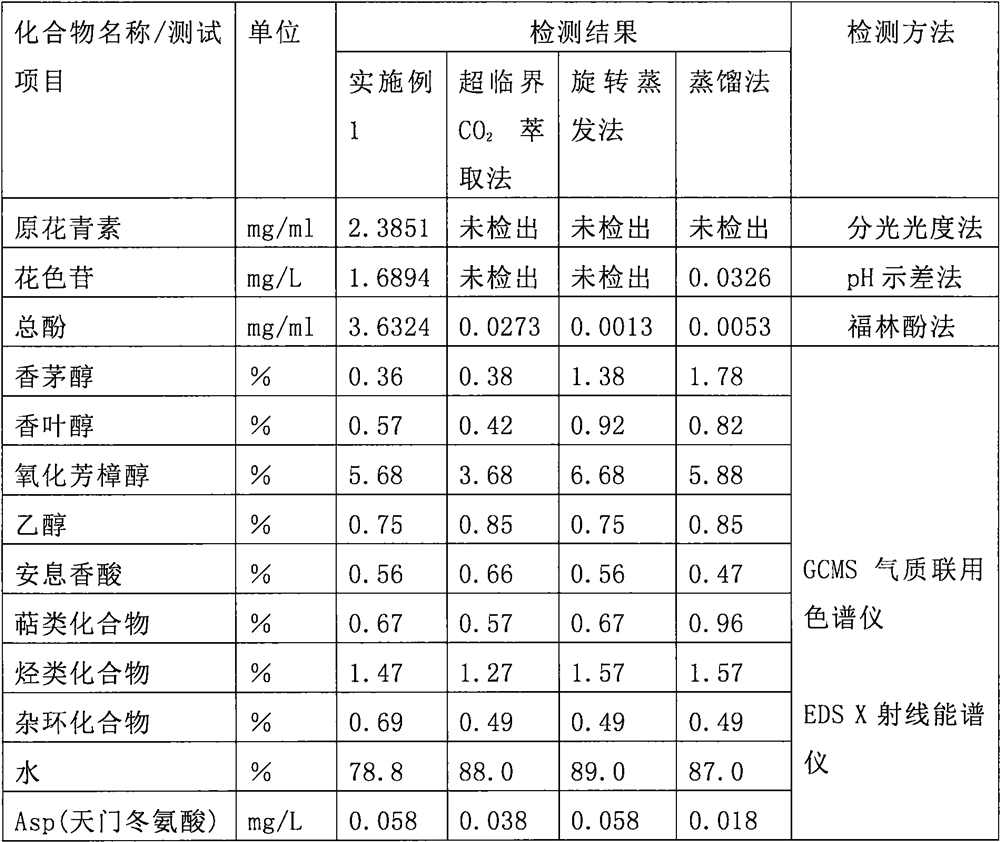

Examples

preparation example Construction

[0033] A kind of preparation method of the cosmetic raw material peony flower extract of the present invention, its specific preparation steps are as follows:

[0034] (1) Harvest the petals of Danfeng peony in the early flowering period, the harvest time is April-May, preferably April 10-30, choose between 6 am and 10 am, the petals of Danfeng peony harvested are the first blooming Petals of 1-10 days, preferably 1-3 days;

[0035] (2) The petals are cryopreserved; the freezing temperature is -5 to -18°C, preferably -10°C;

[0036] (3) Utilize the microwave combined ultrasonic equipment to heat the petals after freezing to inactivate enzymes on the peony flower petals; at the same time play the role of physical sterilization; the ultrasonic frequency is 10~100kHz, preferably 20-50kHz, most preferably 30kHz; microwave The condition is that the temperature of the material is heated to 40-80°C, preferably 58-60°C; the time from feeding to discharging is controlled within 5 minu...

Embodiment 1

[0043] The specific steps of peony flower extract are as follows:

[0044] (1) Harvest 500Kg of Danfeng peony petals that have bloomed for 1-3 days at 6-10 am on April 15;

[0045] (2) Freezing the harvested peony petals at -10°C for 5 days;

[0046] (3) Put the frozen petals into the microwave combined ultrasonic equipment, set the ultrasonic frequency to 30kHz, heat the material temperature to 58-60°C, and control the time from feeding to discharging within 5 minutes; heat peony flower petals to kill enzymes, Simultaneously play the role of physical sterilization;

[0047] (4) Add the peony flower petals that have undergone the enzyme-inactivating and sterilizing treatment in step (3) into a screw press with a screw diameter of Φ300 mm to obtain a peony petal squeeze liquid;

[0048] (5) Put the peony petal squeeze liquid obtained in step (4) to stand for 10 hours, and take the upper liquid to obtain the peony petal feed liquid;

[0049](6) Add 3% activated clay to the up...

Embodiment 2

[0057] (1) Harvest 500Kg of Danfeng peony petals that have bloomed for 5-8 days at 6-10 am on April 18;

[0058] (2) Freezing the harvested peony petals at -10°C for 5 days;

[0059] (3) Put the frozen petals into the microwave combined ultrasonic equipment, set the ultrasonic frequency to 50kHz, heat the material temperature to 55-60°C, and control the time from feeding to discharging within 5 minutes; heat peony flower petals to kill enzymes, Simultaneously play the role of physical sterilization;

[0060] (4) adding the peony flower petals that have been sterilized in step (3) into a screw press machine, the diameter of the screw is Φ300mm, and obtaining the peony petal squeeze liquid;

[0061] (5) Put the peony petal squeeze liquid obtained in step (4) to stand for 15 hours, and take the upper liquid to obtain the peony petal liquid material;

[0062] (6) Add 3% activated carbon to the upper peony petal feed liquid barrel in step (5), stir and heat to 75-80°C in a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com