Random laser manufacturing method based on coupling of silver nanorod metamaterial and luminous body

A technology of random lasers and silver nanorods, which is applied in lasers, laser components, phonon exciters, etc., can solve the problems of laser threshold and insufficient regulation efficiency, and achieve rich research fields and research directions, high output power, low The effect of the threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

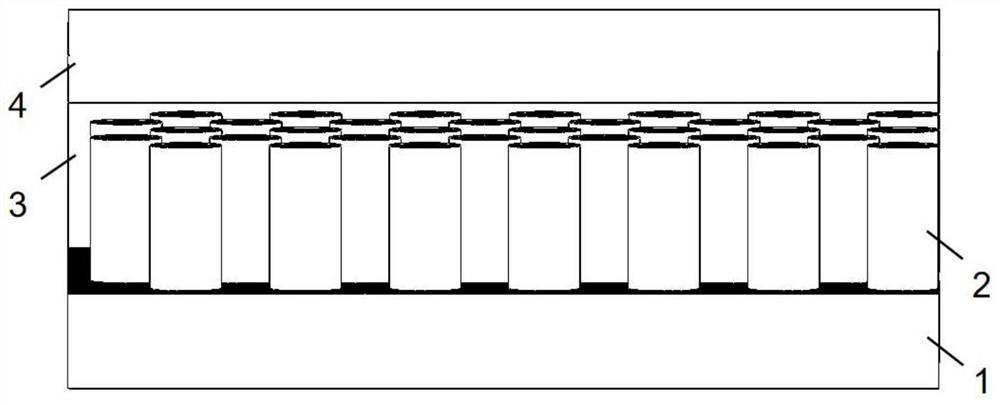

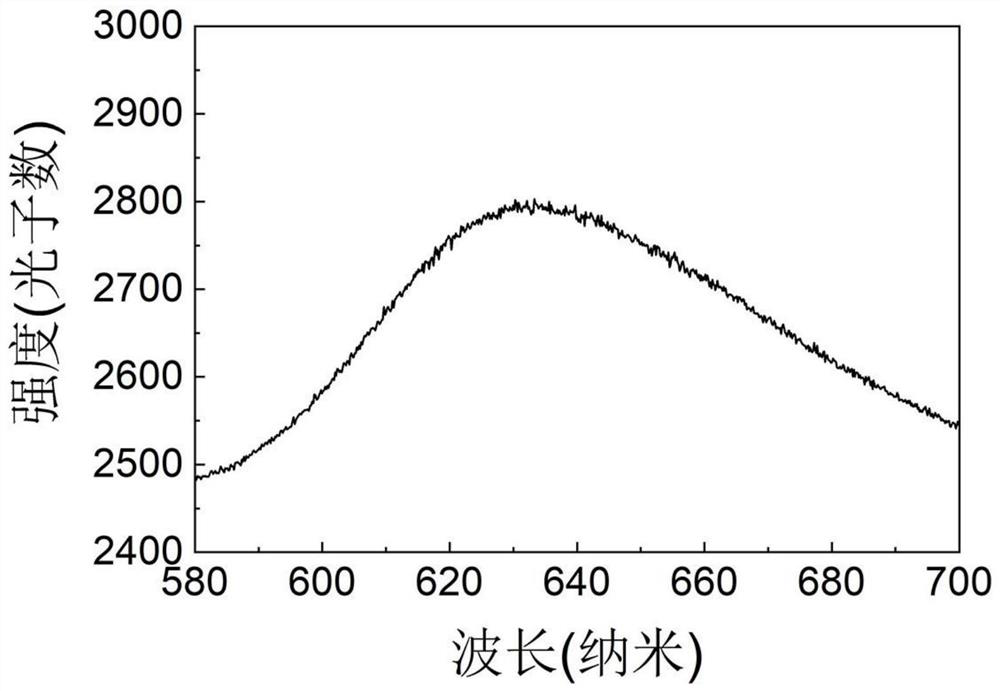

[0030] like figure 2 As shown, the random laser fabrication method based on the coupling of silver nanorod metamaterials and light emitters specifically includes the following steps:

[0031] (1), at 500°C, 10 -2 Under the experimental conditions of Pa, the high-purity aluminum sheet was annealed for 5 hours to obtain an aluminum sheet that is conducive to anodic oxidation;

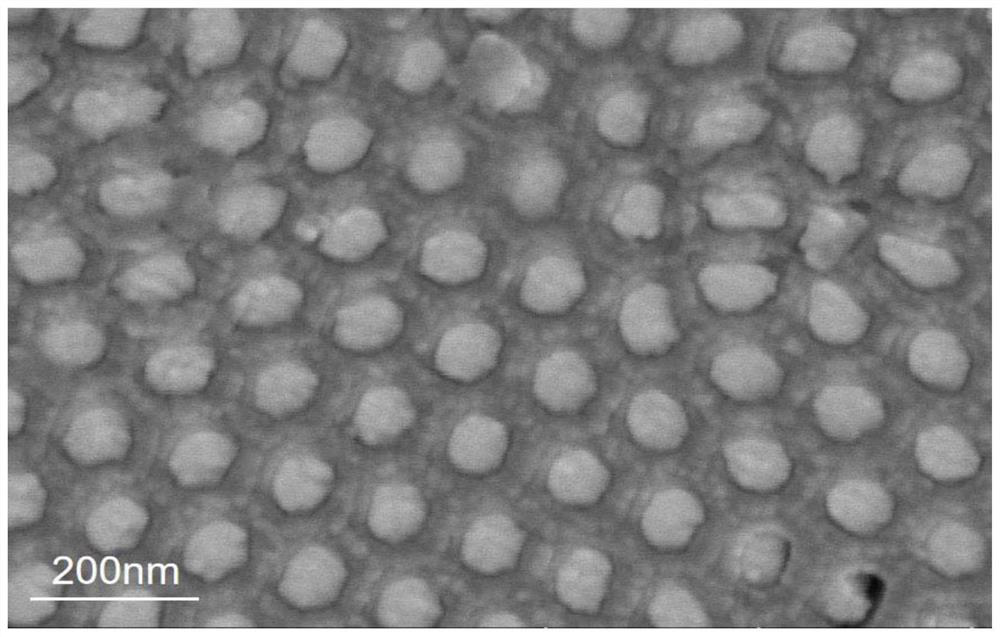

[0032] (2) Orderly and hexagonal close-packed anodized aluminum sheets were prepared by secondary anodic oxidation, wherein they were rinsed and dried, and the unoxidized aluminum on the back of the aluminum oxide sheets was removed with copper chloride solution to obtain Alumina template;

[0033] (3) Float the alumina template in step (2) on the surface of the phosphoric acid solution at 30°C to remove the barrier layer, and then place it again at the bottom of the same phosphoric acid solution to ream the holes for 20 minutes to obtain a full-hole alumina template , at this time, rinse it with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com