N, S co-doped metal-free CNS oxygen reduction catalyst and preparation method thereof

A catalyst and metal-free technology, applied in the direction of fuel cell half-cells and primary battery half-cells, electrical components, battery electrodes, etc., can solve the problems of complex preparation process and environmental pollution, and achieve simple preparation process and low cost. Inexpensive, good for large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

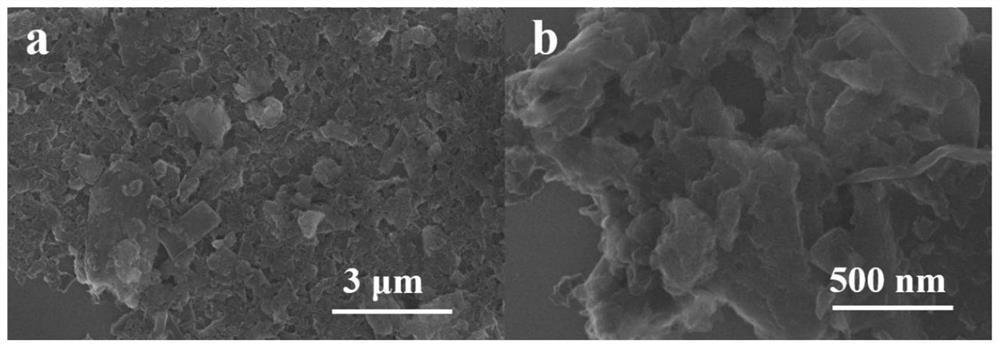

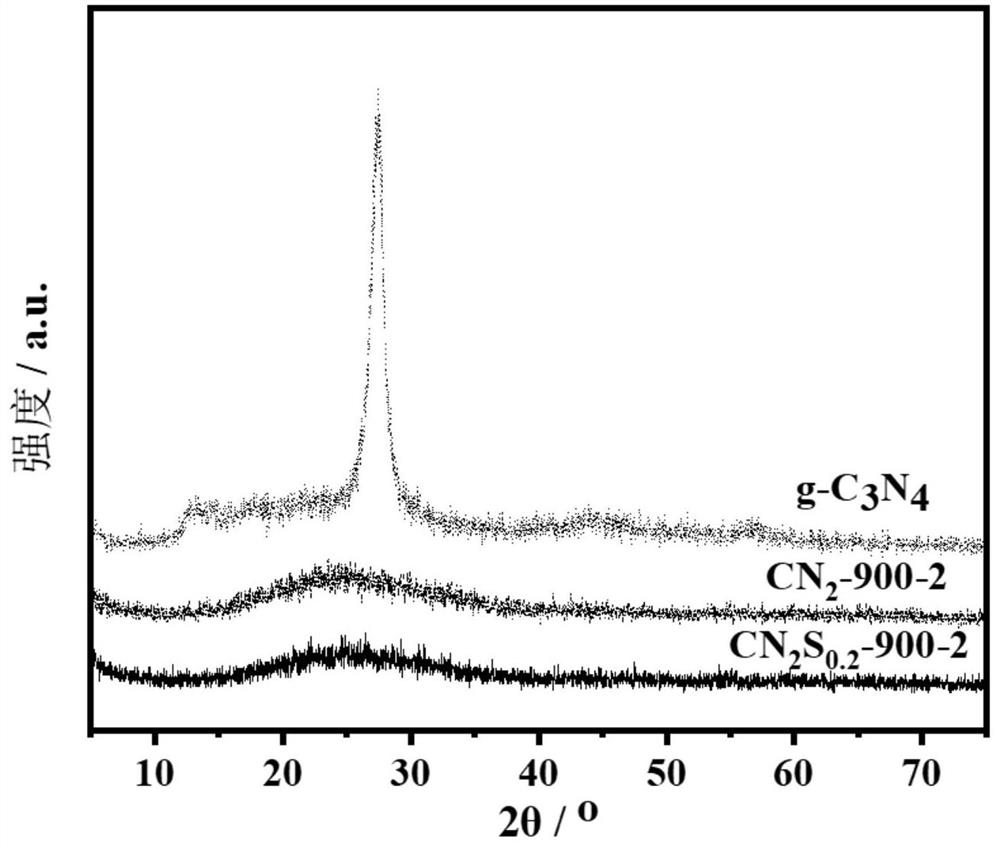

[0034] Example 1: CN 1 S 0.2 -900-2(CN 1 S 0.2 1 in -900-2 means g-C in the raw material 3 N 4 The mass is 1g, 0.2 means the mass ratio of sulfur powder to sodium sulfide is 0.2, 900 means the calcination temperature is 900°C, 2 means the calcination time is 2h)

[0035] 1gg-C 3 N 4 Add to 40mL deionized water, then add 64mg sulfur powder, 280mg sodium sulfide and 200mg glucose, stir for 30min to form a uniform mixed solution A. The mixed solution A was charged into an autoclave, and reacted at 180° C. for 10 h. Then cool to room temperature naturally. Suction filtration, washing, drying in an air oven for 10 hours at 80°C, and then grinding to obtain the CNS catalyst precursor g-C 3 N 4 / CS.

[0036] will g-C 3 N 4 / CS precursor was put into the tube furnace, under N 2 It was calcined under atmosphere for 2 hours, the calcining temperature was 900°C, and the heating rate was 10°C / min. Finally got CN 1 S 0.2 -900-2 Catalyst.

Embodiment 2

[0037] Example 2: CN 2 S 0.2 -900-2(CN 2 S 0.2 2 in -900-2 means g-C in the raw material 3 N 4 The mass is 2g, 0.2 means the mass ratio of sulfur powder to sodium sulfide is 0.2, 900 means the calcination temperature is 900°C, 2 means the calcination time is 2h)

[0038] 2gg-C 3 N 4 Add to 40mL deionized water, then add 64mg sulfur powder, 280mg sodium sulfide and 200mg glucose, stir for 30min to form a uniform mixed solution A. The mixed solution A was charged into an autoclave, and reacted at 180° C. for 10 h. Then cool to room temperature naturally. Suction filtration, washing, drying in an air oven for 10 hours at 80°C, and then grinding to obtain the CNS catalyst precursor g-C 3 N 4 / CS.

[0039] will g-C 3 N 4 / CS precursor was put into the tube furnace, under N 2 It was calcined under atmosphere for 2 hours, the calcining temperature was 900°C, and the heating rate was 10°C / min. Finally got CN 2 S 0.2 -900-2 Catalyst.

Embodiment 3

[0040] Example 3: CN 3 S 0.2 -900-2(CN 3 S 0.2 3 in -900-2 means g-C in the raw material 3 N 4 The mass is 3g, 0.2 means the mass ratio of sulfur powder to sodium sulfide is 0.2, 900 means the calcination temperature is 900°C, 2 means the calcination time is 2h)

[0041] 3gg-C 3 N 4 Add to 40mL deionized water, then add 64mg sulfur powder, 280mg sodium sulfide and 200mg glucose, stir for 30min to form a uniform mixed solution A. The mixed solution A was charged into an autoclave, and reacted at 180° C. for 10 h. Then cool to room temperature naturally. Suction filtration, washing, drying in an air oven for 10 hours at 80°C, and then grinding to obtain the CNS catalyst precursor g-C 3 N 4 / CS.

[0042] will g-C 3 N 4 / CS precursor was put into the tube furnace, under N 2 It was calcined under atmosphere for 2 hours, the calcining temperature was 900°C, and the heating rate was 10°C / min. Finally got CN 3 S 0.2 -900-2 Catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com