Method for producing tablet, and tablet

A technology for tablets and production methods, which is applied in the field of carbonic acid gas foaming composition tablets, can solve problems such as discomfort, achieve the effects of reducing the amount of addition, improving skin absorption, and improving health care and beauty effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

[0123] The present invention will be described in detail through examples below, but the performance of the present invention is not limited thereto.

[0124] Granulation of raw materials for comparison

[0125] operation-1

[0126] The following operations were performed using a fluidized bed granulator GPCG-300CT produced by Powrex.

[0127] In the granulation room where the environment is adjusted to 23°C and 60%RH by air conditioning, 460kg of sodium bicarbonate is added to the fluidized bed granulator GPCG-300CT produced by Powrex and heated until the powder temperature reaches 68°C Put 80kg of PEG#6000 at the same time, and granulate after heating to 72°C. After the end, set the flowing air to 20°C to cool the powder. When the temperature of the powder reached about 35°C, the granules were taken out and put into an external airtight container, and the operation was terminated to obtain granule A01.

[0128] Similarly, the fluidized bed granulator GPCG-300CT produced b...

Embodiment -2

[0212] Operation - 9

[0213] In order to show the effective range of the present invention, the addition amount of the tablet components and the granulation conditions were changed by the following operations, and then the same following operations as in Example-1 were carried out, and the same operations as in the above-mentioned Operation-8 were carried out. The evaluation results are as follows.

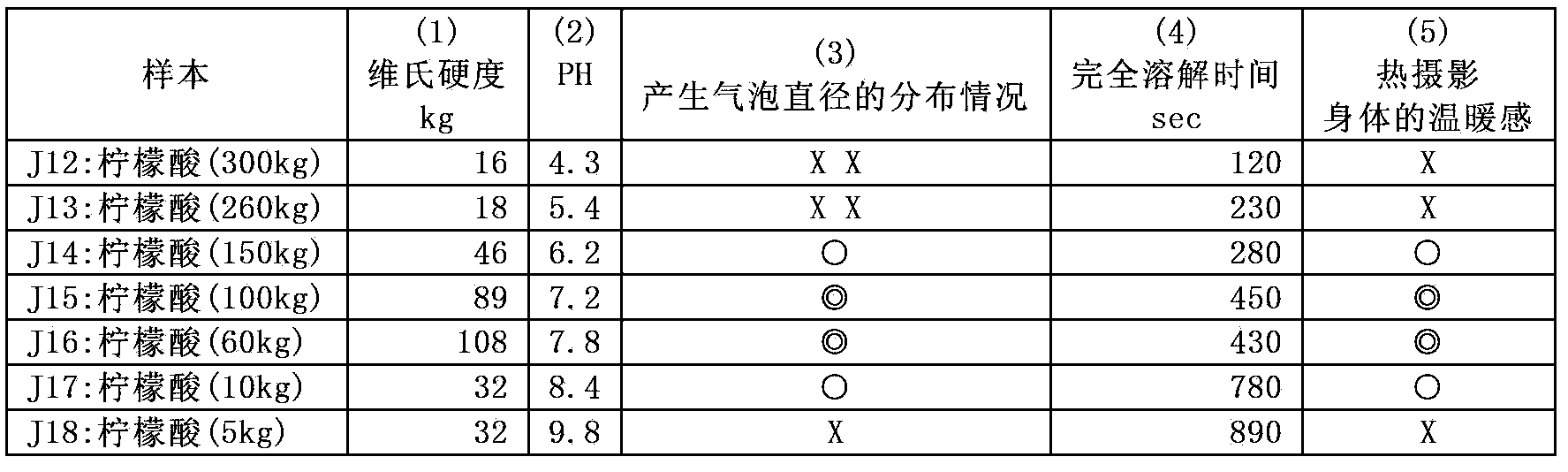

[0214] Promptly add the following amount of citric acid respectively in 500kg granule A4

[0215] J12: Citric acid (300kg)

[0216] J13: Citric acid (260kg)

[0217] J14: Citric acid (150kg)

[0218] J15: Citric acid (100kg)

[0219] J16: Citric acid (60kg)

[0220] J17: Citric acid (10kg)

[0221] J18: Citric acid (5kg)

[0222] Then, 9 kg of anhydrous sodium carbonate, 10 kg of polyethylene glycol #6000 and 1.5 kg of sodium n-octane sulfonate were added to these mixtures respectively, and after mixing, they were passed through Applied Power Industry [Japan Applied Electr...

Embodiment -3

[0227] Operation - 10

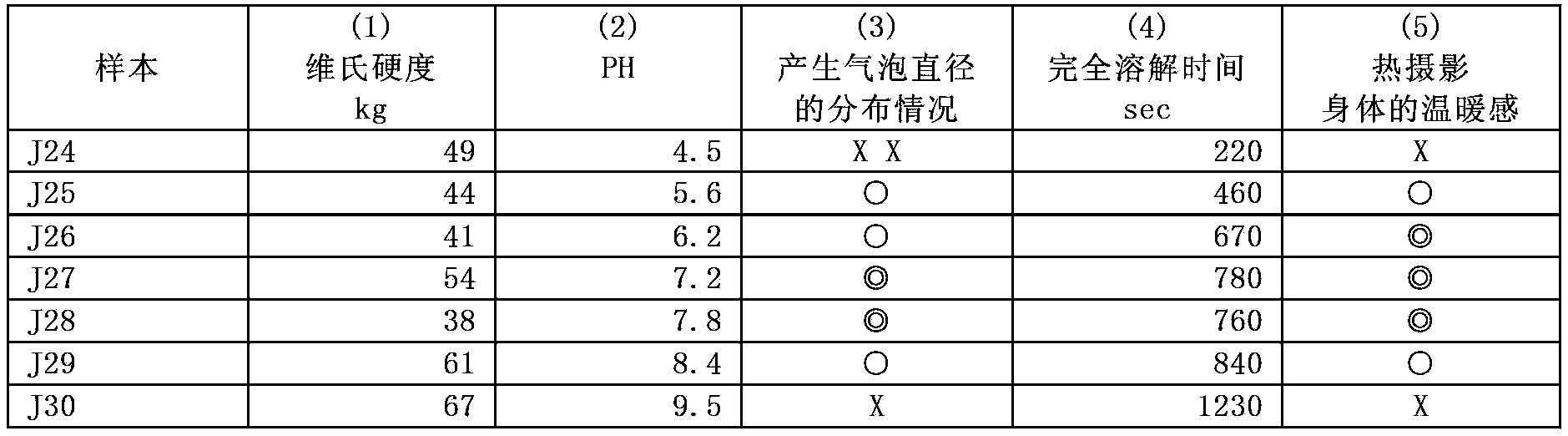

[0228] With respect to the granule A4 of 500kg, add 80kg citric acid and 15kg polyethylene glycol #6000, 1.5kg n-sodium octane sulfonate and mix, take a certain amount of this mixture respectively, add different amounts of sodium carbonate to it, pass Applied The hydraulic type (manual tablet making machine) produced by Power Industry [Nippon Applied Electric Power Company] (former company name: Toyo Hydraulic Equipment Co., Ltd.: type: SPLF-SPF-393) applies a weight of 8t to these mixtures, and produces a diameter of 30mm. Tablets with a thickness of 15mm, respectively select the tablets whose pH value can reach J24=4.5J25=5.6J26=6.2J27=7.2J28=7.8J29=8.4J30=9.5 after dissolving, carry out the same evaluation as Example 3, the results are as follows shown in the table.

[0229] table 3

[0230]

[0231] It can be seen from the above results that when the pH value of the tablet after dissolution is between 5.5 and 8.5, better effects can be obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com