TiNx reinforced high-entropy alloy combined Ti(C,N) based composite material and preparation method thereof

A high-entropy alloy and composite material technology is applied in the field of high-entropy alloy-bonded Ti-based composite materials and their preparation, which can solve the problems of complex preparation process and further improvement of alloy performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

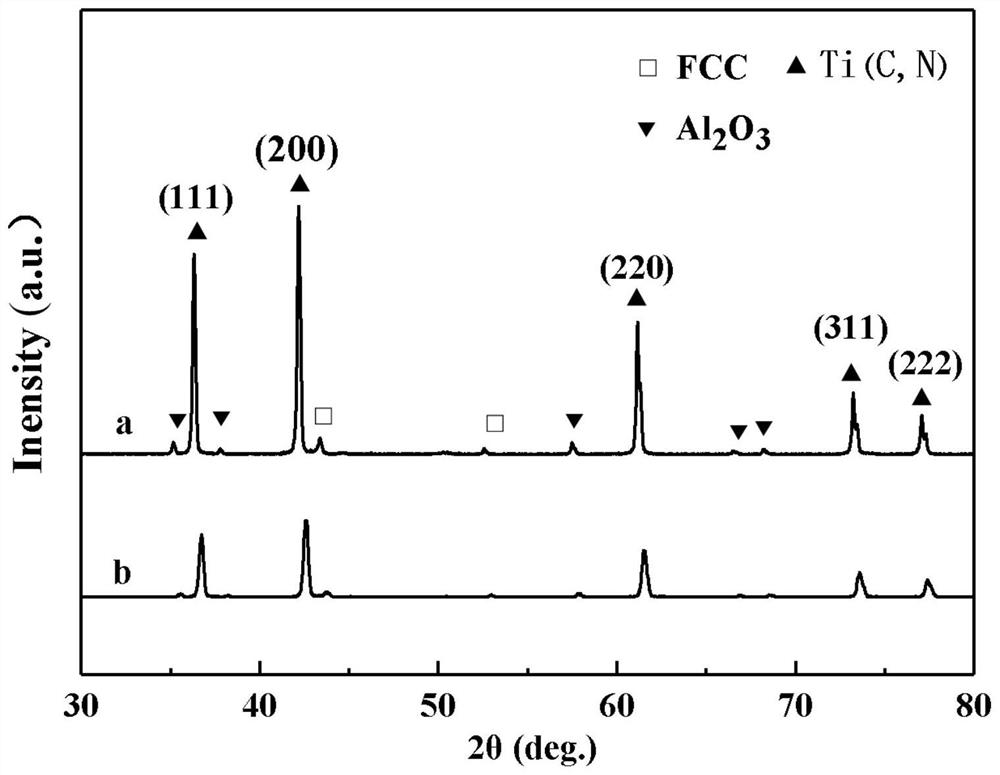

[0022] The invention provides a TiN x A method for preparing a Ti(C,N)-based composite material combined with an enhanced high-entropy alloy, comprising the following steps:

[0023] CoCrNiCuMn powder, TiN x Powder, AlN powder and TiC powder are mixed by ball milling to obtain a mixture; wherein TiN x x in the powder is 0.3-0.9; based on the total mass of the mixture as 100%, the mass percentage of the CoCrNiCuMn powder is 5-20wt.%, the TiN x The mass percentage of the powder is 20-50 wt.%, the mass percentage of the AlN powder is 2-10 wt.%, and the balance is TiC powder;

[0024] The mixture is vacuum hot-pressed and sintered to obtain TiN x Reinforced high-entropy alloy-bonded Ti(C,N)-based composites.

[0025] The present invention will CoCrNiCuMn powder, TiN x The powder, the AlN powder and the TiC powder are ball-milled and mixed to obtain a mixture. In the present invention, the ball mill mixing is preferably carried out in an argon atmosphere; the ball-to-material...

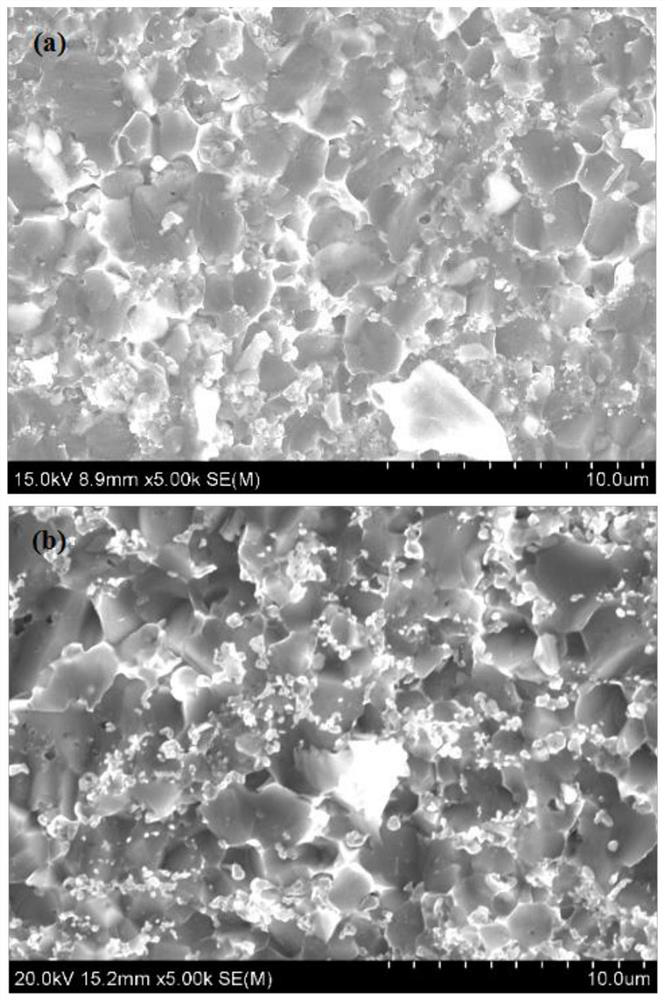

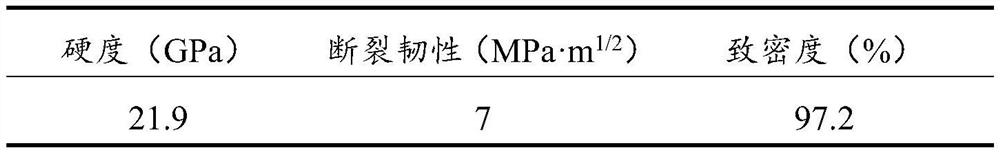

Embodiment 1

[0041] S1. The TiC raw material is subjected to ball milling, the mass ratio of the ball to the material is 10:1, the speed is 400r / min, the ball mill is 40h, every revolution is 5h and the machine is stopped for 10min to dissipate heat, and TiC powder with a particle size below 150nm is obtained;

[0042] S2. Mix 15.24g Ti powder and 4.76g CH in an argon-filled glove box 4 N 2 O is loaded into a WC cemented carbide ball mill tank, the mass ratio of the ball to material is 10:1, the rotating speed is 500r / min, the ball milling time is 30h, and the machine is shut down for 30min every 10h to dissipate heat, so as to obtain TiN with a particle size below 150nm 0.5 powder;

[0043] S3. In a glove box filled with argon, 4.05g Co powder, 3.65gCr powder, 4.04gNi powder, 4.41gCu powder and 3.85gMn powder are mixed into a WC cemented carbide ball mill jar, the mass ratio of ball to material is 10:1, The rotation speed is 600r / min, the ball milling time is 50h, stop for 30min every 5...

Embodiment 2

[0052] S1, the TiC raw material is subjected to ball milling, the mass ratio of the ball to material is 15:1, the speed is 300r / min, the ball mill is 30h, and the machine is stopped for 10min for every 5h to dissipate heat, so as to obtain a TiC powder with a particle size below 150nm;

[0053] S2. Mix 13.915g Ti powder and 6.085g CH in a glove box filled with argon 4 N 2 O is put into a WC cemented carbide ball mill tank, the ball mass ratio is 15:1, the speed is 400r / min, the ball milling time is 40h, every 10h stop for 30min to dissipate heat, and TiN with a particle size below 150nm is obtained 0.7 powder;

[0054] S3. In a glove box filled with argon, 4.05g Co powder, 3.65gCr powder, 4.04gNi powder, 4.41gCu powder and 3.85gMn powder are mixed into a WC cemented carbide ball mill jar, the mass ratio of ball to material is 15:1, The rotation speed is 300r / min, the ball milling time is 30h, stop for 30min to dissipate heat every 5h, stop every 10h to scrape off the raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com