Redox responsive metalloporphyrin complex, preparation method thereof and preparation method of polylactic acid

A technology of metalloporphyrins and complexes, applied in chemical instruments and methods, metallocenes, organic chemistry, etc., can solve problems such as inability to control catalytic efficiency, and achieve high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

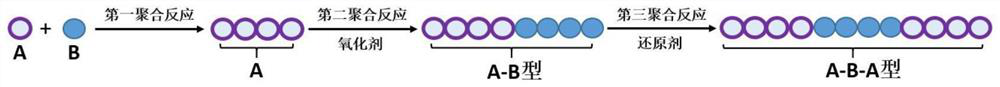

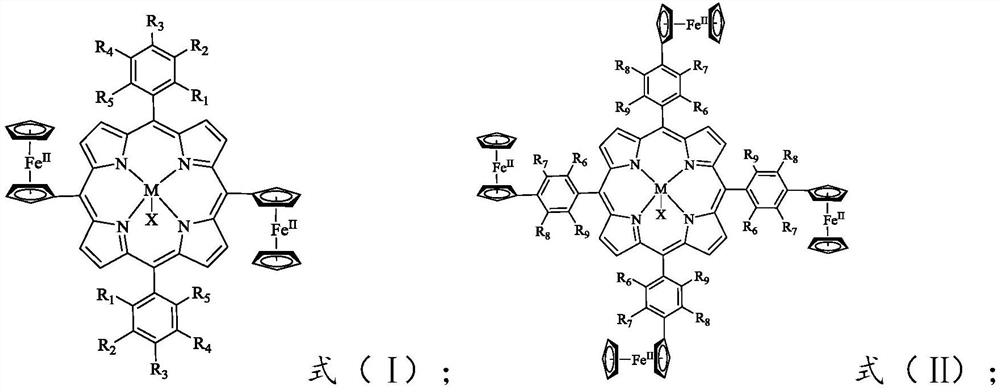

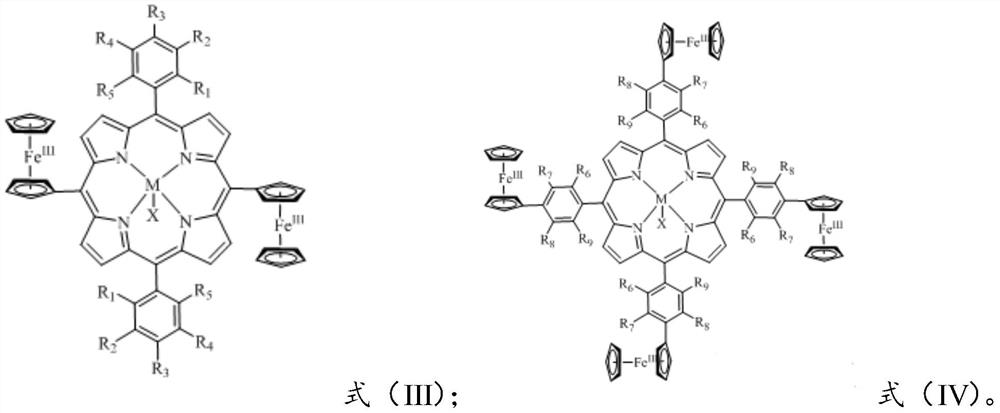

[0061] The present invention provides a preparation method of the redox-responsive metalloporphyrin complex of formula (I) or formula (II) according to any one of the above technical solutions, comprising:

[0062] Under the action of a catalyst, the compound having the structure represented by the formula (V) is subjected to a first reaction with ferrocene formaldehyde to obtain the compound having the structure represented by the formula (VI).

[0063]

[0064] The molar ratio of the compound of the structure shown in the formula (V) to the ferrocene benzaldehyde is 1:(1~1.1); the temperature of the reaction is 25°C~35°C; the time of the reaction is 1h~ 1.5h.

[0065] Reacting the compound having the structure represented by the formula (VI) with a metal salt compound in a solvent to obtain a redox-responsive metalloporphyrin complex of the formula (I);

[0066]

[0067]The molar ratio of the second compound to the metal salt compound is 1:(1~1.5); the metal in the me...

preparation example 1

[0094] Step (A-1), under anhydrous and oxygen-free reaction conditions, dissolve the first compound (20mmol) and ferrocene formaldehyde (20mmol) having the structure shown in formula (5) in 600ml of dry dichloromethane solvent , then added 1.2ml trifluoroacetic acid to the reaction solution, stirred at 25°C for 1h, then added 3.5g DDQ to the obtained reaction solution, and continued stirring at 25°C for 1h to complete the first reaction. Remove the solvent from the obtained reaction solution in vacuo to obtain a crude product, which is then purified by silica gel column chromatography (silica gel, dichloromethane / petroleum ether=1 / 1, V / V) to obtain the formula (5) The second compound of the shown structure has a yield of 18%; high-resolution electrospray mass spectrometry analysis, analysis results [C52H38Fe2N4]: 830.18, found: 830.1.

[0095]

[0096] Step (A-2), dissolving the second compound (1 mmol) of the structure shown in formula (5) obtained in step (A-1) in dry dic...

preparation example 2

[0099] Step (A-1), under anhydrous and oxygen-free reaction conditions, dissolve the first compound (20mmol) and ferrocene formaldehyde (20mmol) having the structure shown in formula (8) in 600ml of dry dichloromethane solvent , then added 1.2ml trifluoroacetic acid to the reaction solution, stirred at 25°C for 1h, then added 3.5g DDQ to the obtained reaction solution, and continued stirring at 25°C for 1h to complete the first reaction. Remove the solvent from the obtained reaction solution in vacuo to obtain a crude product, which is then purified by silica gel column chromatography (silica gel, dichloromethane / petroleum ether=1 / 1, V / V) to obtain the formula (9) The second compound with the structure shown has a yield of 21%; high-resolution electrospray mass spectrometry analysis, analysis results [C52H36Br2Fe2N4]: 986.00, found: 986.0.

[0100]

[0101] Step (A-2), dissolving the second compound (1 mmol) of the structure shown in formula (9) obtained in step (A-1) in dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com