Catalyst of synthetic dodecylphenol and preparation method thereof

A dodecylphenol and catalyst technology, which is applied in the field of dodecylphenol synthesis from dodecylphenol and phenol, can solve the problems of less repetitions, more reaction by-products, poor product color, etc., to increase Si content, change The effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

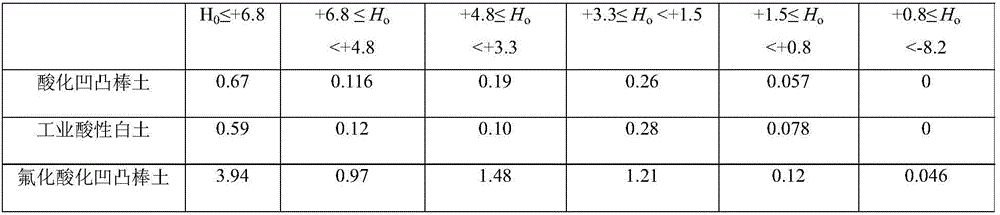

Method used

Image

Examples

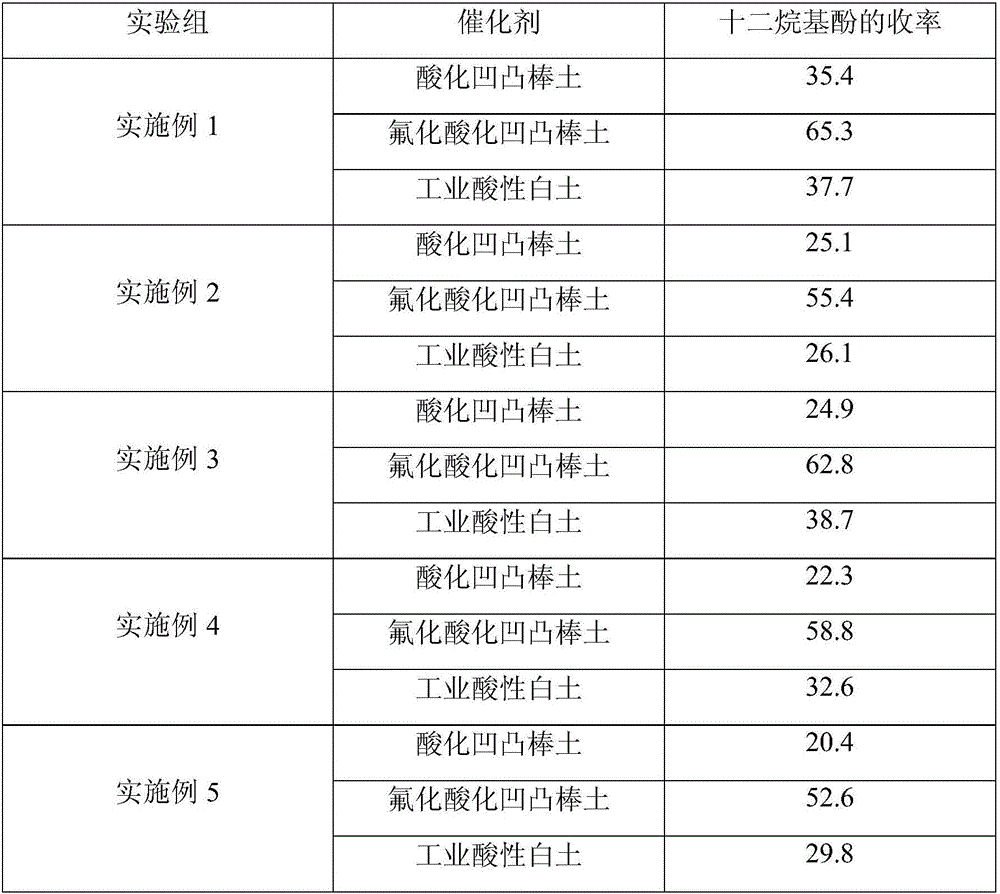

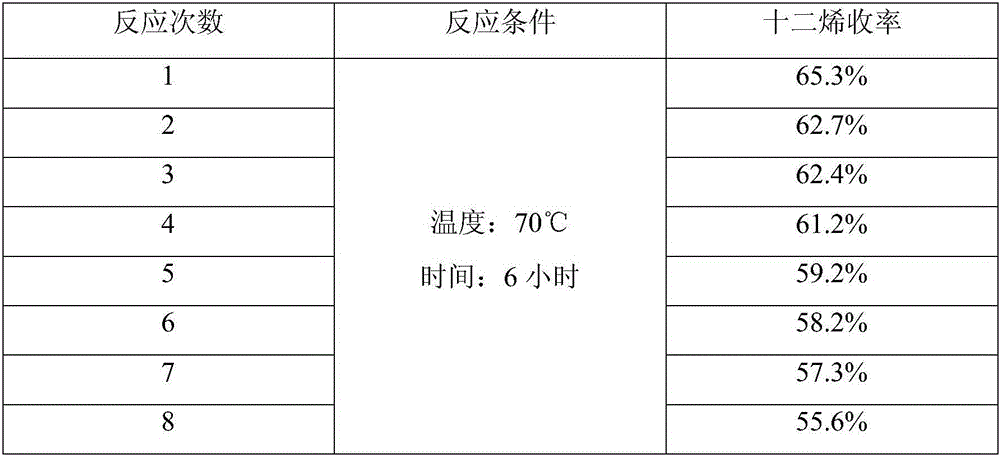

Embodiment 1

[0023] Weigh 10 grams of purified attapulgite into a beaker filled with 40ml of dilute sulfuric acid solution with a concentration of 2mol / L, heat to 70°C, stir for 2 hours, cool, filter, wash until neutral, and dry at 110°C for 12 hours to obtain acidified unevenness Roast clay: Add 10g of acidified attapulgite into a beaker filled with 40ml of 1.5% ammonium fluorosilicate solution, heat to 70°C, stir for 2h, and dry by suction filtration; dry at 110°C for 12h, and roast at 550°C for 8h , to obtain a fluoridated acidified attapulgite catalyst (abbreviated as a fluorinated catalyst, the same below).

[0024] ① in N 2 Under the protection of 0.1 mol of dodecene and 0.2 mol of phenol and 0.49 g of the acidified attapulgite prepared in this example (the amount of acidified attapulgite is 5% of the mass of phenol) was added to the reactor, heated to 70 ° C, Stir for 4 hours. After the reaction, the product was filtered with suction and subjected to vacuum distillation to obtain ...

Embodiment 2

[0028] Weigh 10 grams of purified attapulgite into a beaker filled with 40ml of dilute sulfuric acid solution with a concentration of 2mol / L, heat to 90°C, stir for 2 hours, cool, filter, wash until neutral, and dry at 110°C for 12 hours to obtain acidified unevenness Roast clay: Add 10g of acidified attapulgite into a beaker filled with 40ml of 2% ammonium fluorosilicate solution, heat to 70°C, stir for 2h, filter and dry with suction; dry at 110°C for 12h, and roast at 550°C for 8h , to obtain a fluorination catalyst.

[0029] ① in N 2 Under the protection of 0.1mol dodecene, 0.2mol phenol and 0.25g acidified attapulgite prepared in this example (the amount of acidified attapulgite is 5% of the mass of phenol) was added to the reactor, heated to 50°C, Stir for 6 hours. After the reaction, the product was filtered with suction and subjected to vacuum distillation to obtain the distillate product at a vacuum degree of 1.3 mb and a temperature of 150° C., and finally stored u...

Embodiment 3

[0033] Weigh 10 grams of purified attapulgite into a beaker filled with 40ml of dilute hydrochloric acid solution with a concentration of 2mol / L, heat to 90°C, stir for 2h, cool, filter, wash until neutral, and dry at 110°C for 12h to obtain acidified attapulgite Roast clay: Add 10g of acidified attapulgite into a beaker filled with 40ml of 2.5% ammonium fluorosilicate solution, heat to 80°C, stir for 2h, filter and dry with suction; dry at 110°C for 12h, and roast at 550°C for 8h , to obtain a fluorination catalyst.

[0034] ① in N 2 Under the protection of 0.05 mol dodecene and 0.2 mol of phenol and 0.1 g of acidified attapulgite prepared in this example (the amount of acidified attapulgite is 1% of the mass of phenol) was added to the reactor, heated to 90 ° C, Stir for 8 hours. After the reaction, the product was filtered with suction and subjected to vacuum distillation to obtain the distillate product at a vacuum degree of 1.3 mb and a temperature of 150° C., and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com