Nitrogen-doped porous carbon material supporting CoB nanoparticles, preparation method and application thereof

A nitrogen-doped porous carbon and porous carbon material technology, applied in the field of catalytic chemistry, can solve problems such as unsatisfactory application requirements and reduced catalytic effect, and achieve excellent catalytic performance, facilitate recycling, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

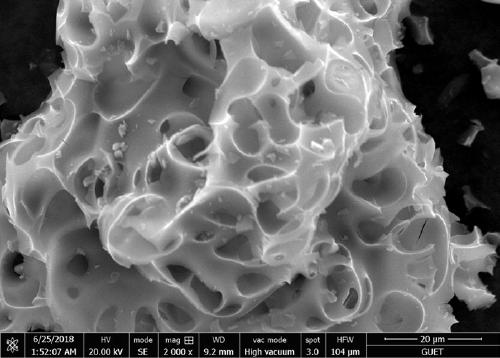

[0042] The preparation method of the nitrogen-doped porous carbon material loaded with CoB nanoparticles, the specific operation steps are as follows:

[0043] Step 1) Preparation of nitrogen-doped porous carbon material, mix the carbon precursor with KOH and urea at a mass ratio of 1.0:3.0:1.0, soak in 30ml deionized water, stir magnetically for 2 hours, dry and put it into the tube Calcined in a furnace under the protection of nitrogen, the calcination activation temperature was 700°C, and the calcination activation time was 2 h to obtain a nitrogen-doped porous activated carbon material; the above product was soaked in 1M HCl solution, washed with deionized water, and suction filtered to neutral, dried and then ground to obtain a nitrogen-doped porous carbon material;

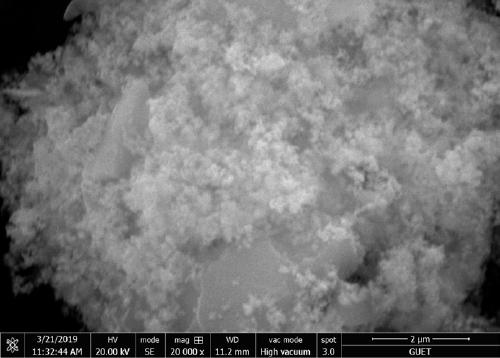

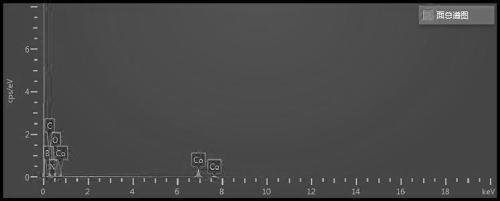

[0044] Step 2) Loading of CoB nanoparticles, weighing 40wt% CoCl 2 .6H 2 0, put into 10ml deionized water, take a certain quality of nitrogen-doped porous carbon, ultrasonic treatment for 1h, take by weigh...

Embodiment 2

[0055] The preparation method of the nitrogen-doped porous carbon material loaded with CoB nanoparticles, the specific operation steps not specified are the same as the above-mentioned Example 1, the difference is: the step 3) CoCl 2 .6H 2 The O loading was 20 wt%.

[0056] The characterization test methods are the same as those in Example 1 above.

[0057] The nitrogen-doped porous carbon material loaded with CoB nanoparticles in Example 2 was subjected to a low-temperature nitrogen isothermal adsorption performance test, and the specific surface area of the nitrogen-doped porous carbon material loaded with CoB nanoparticles was 2524 m 2 g -1 .

[0058] The nitrogen-doped porous carbon material loaded with CoB nanoparticles in Example 2 was subjected to a low-temperature nitrogen isothermal adsorption performance test, and the pore size distribution of the nitrogen-doped porous carbon material loaded with CoB nanoparticles was about 2 nm.

[0059] The nitrogen-doped po...

Embodiment 3

[0062] The preparation method of the nitrogen-doped porous carbon material loaded with CoB nanoparticles, the specific operation steps not specified are the same as the above-mentioned Example 1, the difference is: the step 3) CoCl 2 .6H 2 The O loading was 30 wt%.

[0063] The characterization test methods are the same as those in Example 1 above.

[0064] The nitrogen-doped porous carbon material loaded with CoB nanoparticles in Example 3 was subjected to a low-temperature nitrogen isothermal adsorption performance test, and the specific surface area of the nitrogen-doped porous carbon material loaded with CoB nanoparticles was 2524 m 2 g -1 .

[0065] The nitrogen-doped porous carbon material loaded with CoB nanoparticles in Example 3 was subjected to a low-temperature nitrogen isothermal adsorption performance test, and the pore size distribution of the nitrogen-doped porous carbon material loaded with CoB nanoparticles was about 2 nm.

[0066] The nitrogen-doped po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com