Process method and equipment for efficient crushing and grinding of crystalline graphite with large scales

A technology of crystalline graphite and process method, which is applied in grain processing, solid separation, etc., can solve the problems of stepped fracture of flake graphite sheets, large proportion of energy consumption, and low efficiency of crushing and grinding, so as to improve regrinding and fine grinding Improve the efficiency of mineral processing, improve the indicators of concentrate products, and shorten the effect of the mineral processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention provides a process method for efficient crushing and grinding of crystalline graphite that protects large scales. The process mineralogy research shows that: the fixed carbon content of raw ore is 13.39%, and the gangue minerals mainly include quartz, muscovite, potassium feldspar, etc.; raw ore graphite The intercalation particle size is relatively coarse, and the content of +100 mesh particle size reaches 68.78%. Most of the coarse-grained crystals have obvious kinks, and most of the graphite and mica are closely symbiotic, and they are mutually wrapped or interlayered. The loss of large flakes in conventional ball mill grinding process is serious.

[0036] Process method of the present invention comprises:

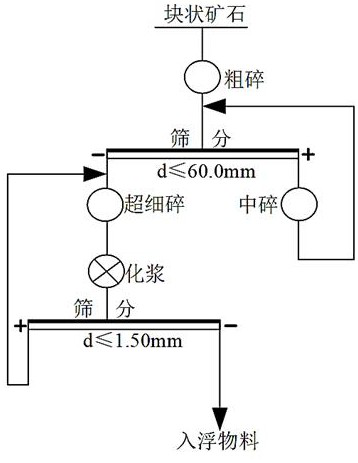

[0037] In step (1), the massive ore is sent to the jaw crusher 3 through the bar feeder 2 for coarse crushing, and the coarse crushed product d max =200.0mm, the coarsely crushed material is screened by a circular vibrating screen 8 with a sieve ho...

Embodiment 2

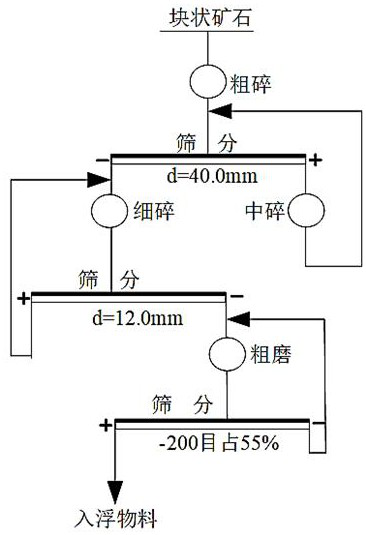

[0043] The invention provides a high-efficiency crushing and grinding process for crystalline graphite with large scales protected, taking a graphite sample from a certain area in Heilongjiang as an example. Respectively according to the present invention and conventional crushing process (according to attached image 3 The process shown above) is crushed and ground, and the fineness of the product is controlled at -0.147mm, which accounts for about 50%. attached Figure 4 The process shown is carried out, the test results are shown in Table 2, and the concentrate screening results are shown in Table 3.

[0044] Table 1 Particle size composition and fixed carbon distribution of products with different crushing and grinding processes

[0045]

[0046] It can be seen from Table 1 that under the same fineness (-0.147mm particle size accounts for about 48%), the crushing process and method of the present invention are very effective for protecting large scales (+0.147mm), esp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com