Methods for preparing and using pre-reduced fluxed pellets by taking steel slag as part of raw materials

A technology of flux and steel slag, which is applied in the field of pre-reduction flux pellet preparation, can solve the problems of failing to realize the reasonable application of secondary product dedusting ash and not mentioning steel slag, so as to enhance market competitiveness and realize green manufacturing , The effect of reducing the cost of blast furnace production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Dust removal ash mixture ratio and processing plan

[0040] See Table 1 for the dedusting ash mixture ratio plan.

[0041] Table 1: Proportioning scheme of dust removal ash mixture

[0042] raw material name Proportion of mass mixing,% Blast furnace gravity ash25 Dry dust removal20 Gas mud25 Steelmaking Dust30

[0043] See Table 2 for the processing plan of dust removal ash mixture.

[0044] Table 2: Proportioning scheme of dust removal ash mixture

[0045] project Value Drying temperature, ℃200 Drying time, h5 Grinding time, min40 Mixing time, min35 Mixing particle size (less than 0.074mm accounting for the proportion of mass),%85

[0046] Pre-reduction flux pelletizing plan

[0047] See Table 3 for the pre-reduction flux pelletizing plan.

[0048] Table 3: Pre-reduction flux pelletizing plan

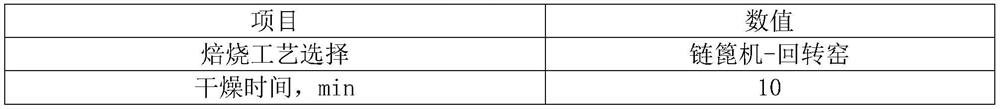

[0049] project Value Steel slag grain size range, mm 2~4 Grinding time, min40 Granularity of steel slag powder (in 0.074mm in mass proportion),%85 Dust removal ash ...

Embodiment 2

[0065] Dust removal ash mixture ratio and processing plan

[0066] See Table 7 for the ratio of dust removal ash mixture.

[0067] Table 7: Proportioning scheme of dust removal ash mixture

[0068] raw material name Proportion of mass mixing,% Blast furnace gravity ash30 Dry dust removal30 Gas mud10 Steelmaking Dust30

[0069] See Table 8 for the processing plan of dust removal ash mixture.

[0070] Table 8: Proportion plan of dust removal ash mixture

[0071] project Value Drying temperature, ℃250 Drying time, h6 Grinding time, min40 Mixing time, min40 Mixing particle size (less than 0.074mm accounting for the proportion of mass),%88

[0072] Pre-reduction flux pelletizing plan

[0073] See Table 9 for the pelletizing plan of pre-reduced flux pellets.

[0074] Table 9: Pre-reduction flux pelletizing plan

[0075] project Value Steel slag grain size range, mm 2~4 Grinding time, min40 Granularity of steel slag powder (in 0.074mm in mass proportion),%86 Dust removal...

Embodiment 3

[0090] Dust removal ash mixture ratio and processing plan

[0091] See Table 13 for the dedusting ash mixture ratio plan.

[0092] Table 13: Proportion plan of dust removal ash mixture

[0093] raw material name Proportion of mass mixing,% Blast furnace gravity ash30 Dry dust removal35 Gas mud15 Steelmaking Dust20

[0094] See Table 14 for the processing plan of dust removal ash mixture.

[0095] Table 14: Proportion plan of dust removal ash mixture

[0096] project Value Drying temperature, ℃300 Drying time, h7 Grinding time, min35 Mixing time, min35 Mixing particle size (less than 0.074mm accounting for the proportion of mass),%88

[0097] Pre-reduction flux pelletizing plan

[0098] See Table 15 for the pelletizing plan of pre-reduced flux pellets.

[0099] Table 15: Pre-reduction flux pelletizing plan

[0100] project Value Steel slag grain size range, mm 2~4 Grinding time, min45 Granularity of steel slag powder (in 0.074mm in mass proportion),%88 Dust removal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com