Composite negative pole piece, preparation method thereof and lithium ion battery

A technology of negative pole piece and composite substrate, applied in the direction of negative electrode, battery electrode, secondary battery, etc., can solve the problems of poor integrity and compatibility, deterioration of full battery cycle, weakening the advantages of lithium metal, etc., and achieve cycle life. Increase, is conducive to stable and uniform deposition, improve the effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

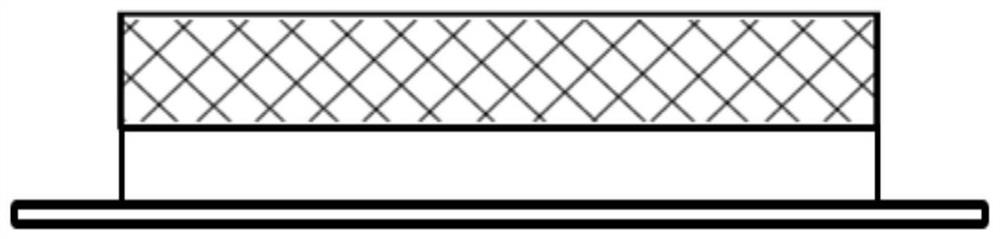

[0053] Embodiment 1 proposes a kind of composite negative pole sheet and lithium ion battery, and its preparation method comprises the following steps:

[0054] 1. Preparation of composite negative electrode sheet

[0055] (1) Mix carbon fibers, PLA, surfactants, and toughening compatibilizers in a mass ratio of 5.3:1.8:0.2:0.1 and place them in a beaker, add a certain amount of chloroform, Stir evenly at a speed of 500rpm for 3 hours to form a homogeneous solution. After the stirring is completed, the slurry is fully volatilized to obtain a block-shaped solid, vacuum-dried at 50°C for 12 hours, and sheared and ground to obtain a granular 3D printing material precursor. body.

[0056] (2) Shear and grind the precursor of the granular 3D printing material and send it into the screw extruder for blending and silk making. The diameter of the wire is 0.40 mm, and the wire is coiled.

[0057] (3) Cold-press metal lithium foil and Cu current collector into a Li-Cu layered structu...

Embodiment 2

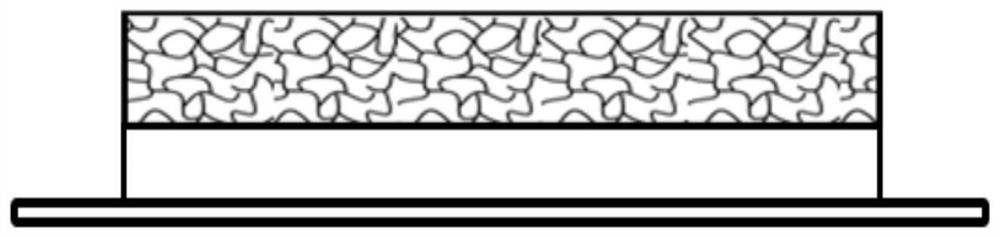

[0065] Embodiment 2 proposes a kind of composite negative pole sheet and soft pack polymer lithium ion battery, and its preparation method comprises the following steps:

[0066] 1. Preparation of composite negative electrode sheet

[0067] (1) Mix carbon fiber, polycaprolactone (PCL) and surfactant according to the mass ratio of 6:1.8:0.1 and put them in a beaker. Stir at a uniform speed for 3 hours to form a homogeneous solution. After the stirring is completed, the slurry is fully volatilized to obtain a block-shaped solid, vacuum-dried at 59°C for 18 hours, and sheared and ground to obtain a granular 3D printing material precursor.

[0068] (2) The precursor of the granular 3D printing material is sheared and ground and sent to the screw extruder for blending and silk making. The silk making temperature is 73°C, and it is pulled by a tractor at a speed of 22cm / min, and extruded The diameter of the wire is 0.80 mm, and the wire is coiled.

[0069] (3) Metal lithium foil a...

Embodiment 3

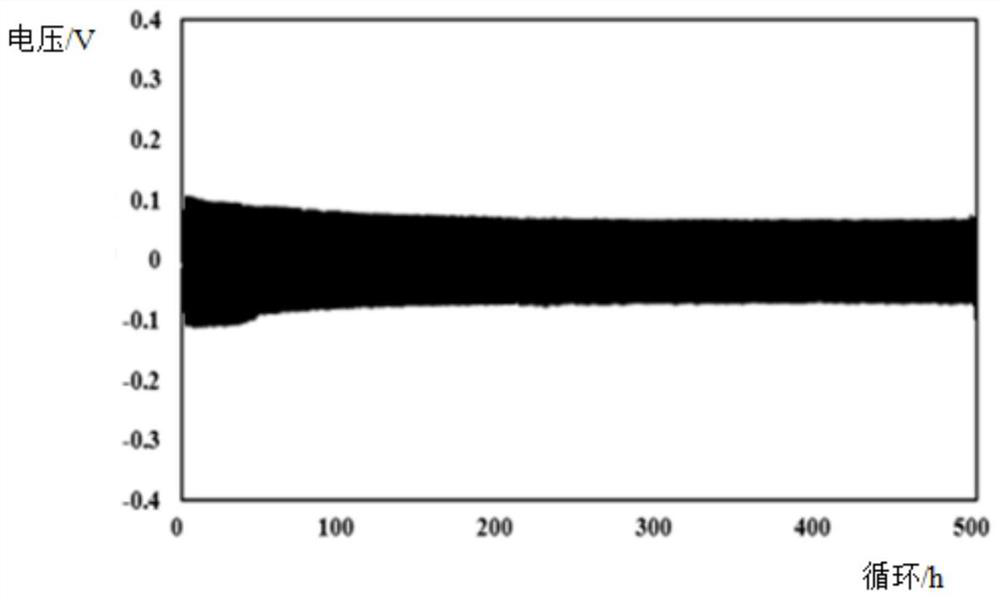

[0077] Embodiment 3 proposes a composite negative pole piece and an all-solid-state abrasive lithium-ion battery, and its preparation method comprises the following steps:

[0078] 1. Preparation of composite negative electrode sheet

[0079] (1) Mix carbon fiber, acrylonitrile-butadiene-styrene plastic (ABS), surfactant, and toughening compatibilizer according to the ratio of 5.1:1.3:0.15:0.05 by mass and put them in a beaker. Add a certain amount of dichloromethane, and stir evenly at room temperature at a speed of 800rpm for 6h to form a homogeneous solution. After the stirring is completed, the slurry is fully volatilized to obtain a block-shaped solid, vacuum-dried at 50°C for 11h, and Granular 3D printing material precursors were obtained after shearing and grinding.

[0080] (2) The precursor of the granular 3D printing material is sheared and ground and sent to the screw extruder for blending and silk making. The silk making temperature is 226°C, and it is pulled by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com