Preparation method of cage-shaped ferronickel bimetallic phosphide loaded nitrogen-doped porous carbon material

A nitrogen-doped porous carbon and bimetallic technology, which is applied in the preparation/purification of carbon, phosphides, phosphorus compounds, etc., can solve the problems of poor stability of metal phosphides, improve electrocatalytic performance, and increase charge transfer channel, the effect of increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of roughened melamine sponge (MS): first cut the melamine sponge into 2 × 2 × 2cm with scissors 3 The cube was washed with deionized water in a magnetic stirrer for 15 minutes, and then the cleaned sponge was placed in a 3.0mol / L sodium hydroxide solution, heated in a water bath at 50°C for 30 minutes, and then washed with deionized water Wash 3 times and dry at 60°C to obtain a roughened melamine sponge (MS).

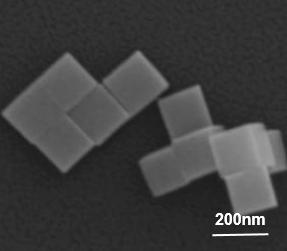

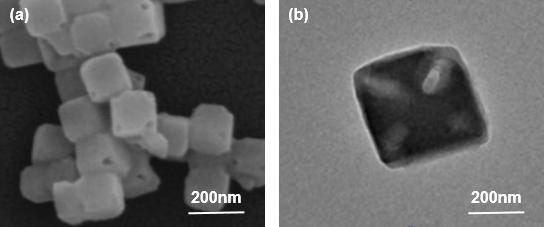

[0033] 2. Preparation of nickel-iron bimetallic Prussian blue precursor coated with melamine sponge: nickel acetate and trisodium citrate were dissolved in 200 mL of deionized water at a molar ratio of 1:1, stirred for 30 minutes, and recorded as solution A ; Put the roughened melamine sponge prepared in step 1 into solution A, and sonicate for 30 minutes. Dissolve potassium ferricyanide, whose molar mass is 1 / 2 that of nickel acetate, in 300 mL of deionized water, and stir the solution until it becomes clear, and record it as solution B. Then s...

Embodiment 2

[0037] 1. Preparation of roughened melamine sponge (MS): first cut the melamine sponge into a cube of 2 × 2 × 2cm3 with scissors, then wash it in a magnetic stirrer with deionized water for 30 minutes, and then place the cleaned sponge in In a 4.0 mol / L sodium hydroxide solution, heat in a water bath at 60°C for 40 minutes, wash with deionized water three times, and dry at 70°C to obtain a roughened melamine sponge (MS).

[0038] 2. Preparation of nickel-iron bimetallic Prussian blue precursor coated with melamine sponge: nickel acetate and trisodium citrate were dissolved in 250 mL of deionized water at a molar ratio of 1:1.2, stirred for 45 minutes, and recorded as solution A; Put the roughened melamine sponge prepared in step 1 into solution A and sonicate for 40 min. Dissolve potassium ferricyanide, whose molar mass is 1 / 2 that of nickel acetate, in 400 mL of deionized water, and stir the solution until it becomes clear, and record it as solution B. Then slowly add the so...

Embodiment 3

[0042] 1. Preparation of roughened melamine sponge (MS): first cut the melamine sponge into a cube of 2 × 2 × 2cm3 with scissors, then wash it in a magnetic stirrer with deionized water for 45 minutes, and then place the cleaned sponge in In a 5.0 mol / L sodium hydroxide solution, heat in a water bath at 70 °C for 45 minutes, wash with deionized water three times, and dry at 80 °C to obtain a roughened melamine sponge (MS).

[0043] 2. Preparation of nickel-iron bimetallic Prussian blue precursor coated with melamine sponge: nickel acetate and trisodium citrate were dissolved in 300 mL of deionized water at a molar ratio of 1:1.5, stirred for 60 minutes, and recorded as solution A ; Put the roughened melamine sponge prepared in step 1 into solution A and sonicate for 45 minutes. Dissolve potassium ferricyanide, whose molar mass is 1 / 2 that of nickel acetate, in 500 mL of deionized water, and stir the solution until it becomes clear, which is referred to as solution B. Then slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com