Melt-blown non-woven fabric electret adding device and adding method

A technology of melt-blown non-woven fabrics and adding devices, which is applied in the directions of melt-spinning, non-woven fabrics, textiles and papermaking, etc., can solve the problems of limited filtration efficiency improvement, downtime for maintenance, broken filaments, etc., and achieves good filtration performance stability. , The effect of maintaining lasting static electricity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

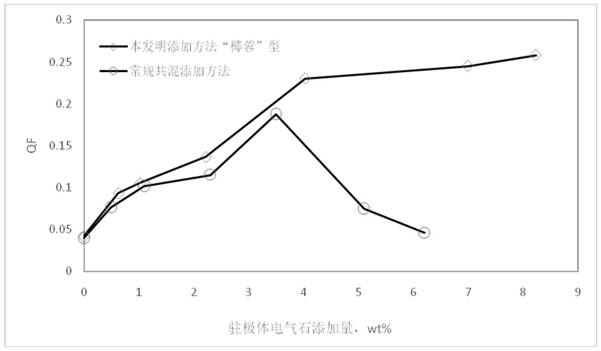

[0041] Embodiment 1: The electret material tourmaline is mixed and co-extruded with polypropylene having a melt index MFI=1500 to form an electret masterbatch. Polypropylene particles with a melt index MFI=1800 are used, and the melt-blown fiber resin and the electret masterbatch (the mass percentage of tourmaline added is 0.5wt%-6.2wt%) are added to the extruder for melt blending at the same time, and the extrusion temperature is 250°C , the melt temperature is 255°C, and it is sprayed into filaments in the form of a blend through the spinneret hole to form a fine spinning stream. The temperature of the spinning box is 255°C, and there are high-speed hot airflows on both sides of it to clamp the high-temperature melt stream. The temperature of the traction wind is 265°C, and ultrafine fiber form is formed after traction and stretching. Gather into a network structure at a certain speed on the receiving device, with a weight of about 30g / m 2 . The fiber web is subjected to h...

Embodiment 2

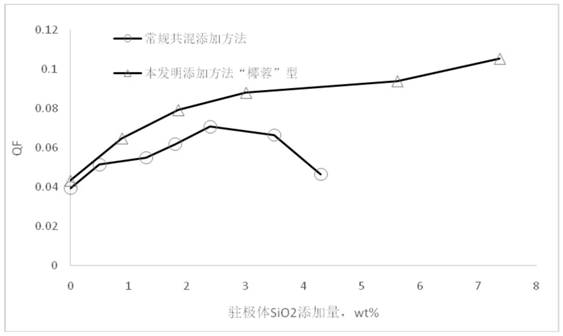

[0045] Embodiment 2: Electret material gas phase method SiO 2 Mixed and co-extruded with polypropylene with melt index MFI=1500 to form electret masterbatch. Polypropylene particles with melt index MFI=1800, melt-blown fiber resin and electret masterbatch (SiO 2 Adding mass percentage is 0.5wt%-4.3wt%) at the same time into the extruder for melt blending, the extrusion temperature is 250 ° C, the melt temperature is 255 ° C, and the blend is sprayed into filaments through the spinneret hole to form a spinning Fine silk flow, the temperature of the spinning box is 255°C, the high-speed hot air flow on both sides clamps the high-temperature melt fine flow, the temperature of the traction wind is 265°C, and the ultra-fine fiber form is formed after traction and stretching. Gather into a network structure at a certain speed on the receiving device, with a weight of about 30g / m 2 . The fiber web is subjected to high-voltage electrostatic action (10kV) to obtain a melt-blown elec...

Embodiment 3

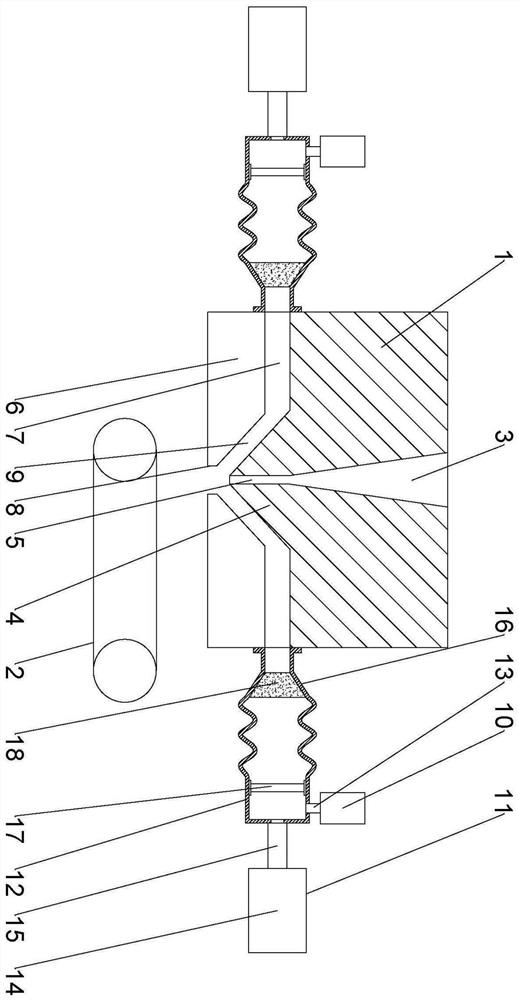

[0049] Example 3: Polypropylene particles with a melt index MFI=1800 are added to an extruder for melt extrusion. The extrusion temperature is 250°C, and the melt temperature is 255°C. The wire box temperature is 255°C. Tourmaline powder is dispersed into a concentration of 1-10g / m by an aerosol generator 3 1. The aerosol with an average particle diameter of 0.1 μm is added to the drafting airflow duct, the temperature of the drafting air is 265 °C, and the tourmaline that enters the air gap of the melt blown component is blown out with the high-speed hot airflow on both sides of the spinning stream. The electret can be attached to the high temperature melt. The fine spinning stream is drawn and stretched by high-speed airflow to form an ultra-fine fiber shape. Gather into a network structure at a certain speed on the receiving device, with a weight of about 30g / m 2 . The fiber web is subjected to high-voltage electrostatic action (10kV) to obtain a melt-blown electret fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com