Ultralow-temperature nodular cast iron and preparation method thereof

A ductile iron, ultra-low temperature technology, applied in the field of metal casting, can solve the problems of continuous improvement of the mechanical properties of ductile iron materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

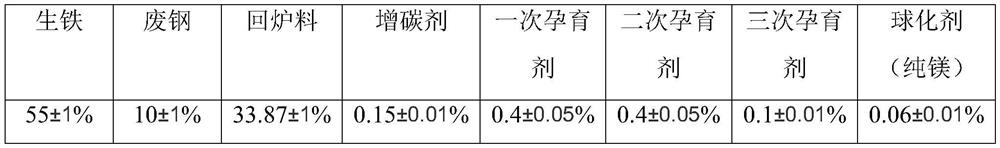

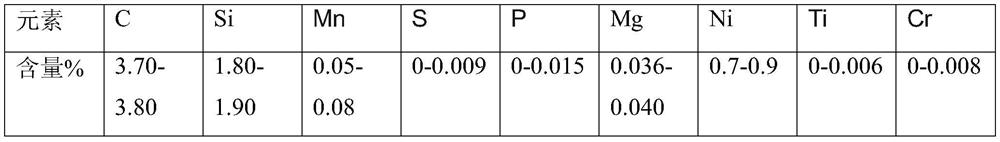

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Screening experiment of key parameters of the preparation method of low temperature ductile iron.

[0032] 1. Screening experiment of C element content: start from 3.5%, increase by 0.1% each time, see Table 2.

[0033] Table 2. The effect of different content of C elements on low temperature impact energy J.

[0034] C% 3.5 3.6 3.7 3.8 3.9 Low temperature impact energy J 10.2 10.8 11.5 12.5 11.1

[0035] 2. Screening experiment of Si element content: start from 1.6%, increase by 0.1% each time, see Table 3.

[0036] Table 3. Effect of different contents of Si element on low temperature impact energy J.

[0037] Si% 1.6 1.7 1.8 1.9 2.0 Low temperature impact energy J 9.6 10.8 12.8 12.7 12.6

[0038] 3. Screening experiment of Mg element content: start the experiment from 0.030%, increase by 0.002% each time, see Table 4.

[0039] Table 4. The effect of different contents of Mg element on low temperatur...

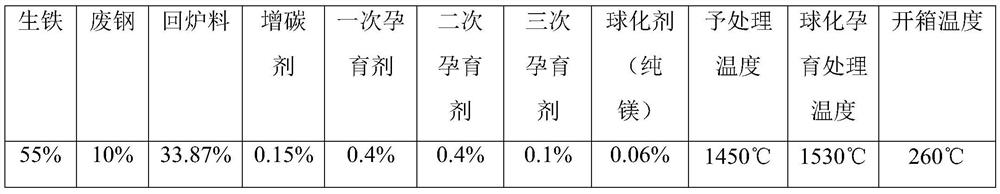

Embodiment 2

[0060] Example 2 Production process of ultra-low temperature ductile iron.

[0061] The preparation method of ultra-low temperature ductile iron specifically includes the following steps.

[0062] Step 1, raw material preparation.

[0063] (1) Weigh Benxi Steel’s super-grade Q10 pig iron, Mn≦0.1%, S≦0.03%, P≦0.015%, Ti≦0.010%, Cr≦0.015% according to the burden ratio in Table 7, and return it to the furnace charge.

[0064] (2) Add pig iron to the 1-ton intermediate frequency furnace according to the charge ratio in Table 8, return the charge, and start smelting scrap steel. When molten iron appears in the intermediate frequency furnace, add carburant to continue smelting. When the temperature of the molten iron reaches 1450°C, the molten iron is pretreated.

[0065] Table 8. Charge ratio (mass percentage).

[0066]

[0067] Step 2, molten iron pretreatment.

[0068] 1) When the temperature of the molten iron reaches 1450°C, measure the S content of the molten iron to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spheroidization rate | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com