Photocatalyst coating and preparation method thereof

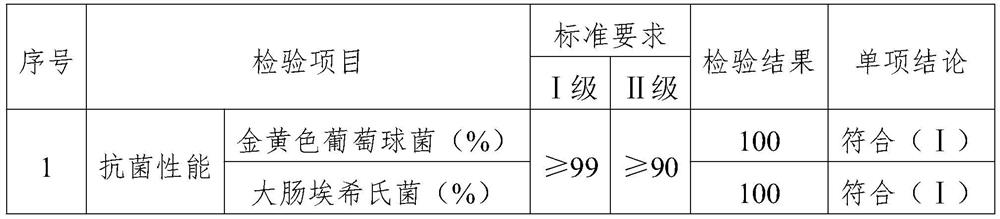

A photocatalyst and coating technology, applied in the field of coatings, can solve problems such as poor antibacterial properties, inability to improve indoor environment, and slow release of small molecule harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

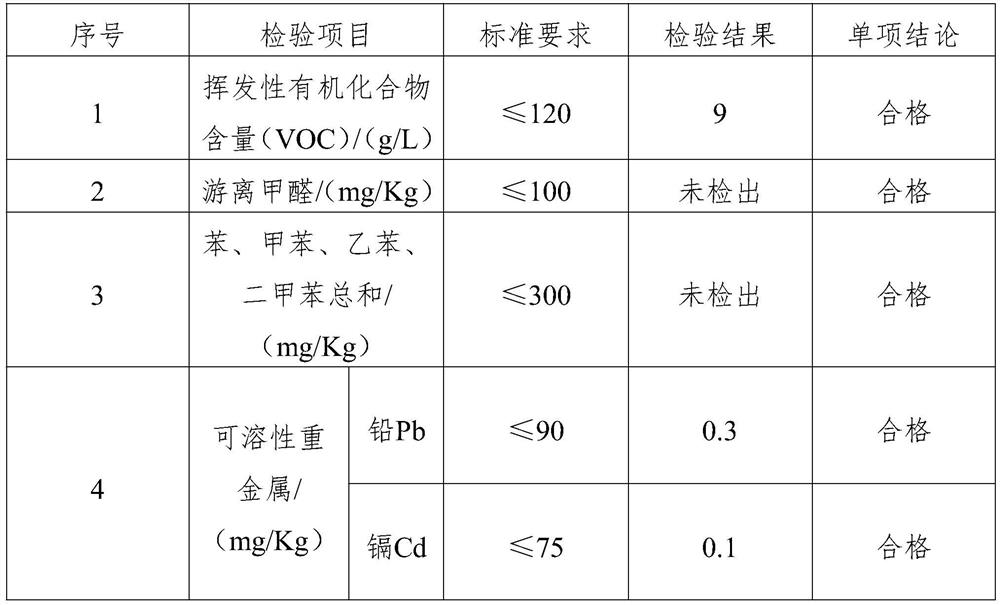

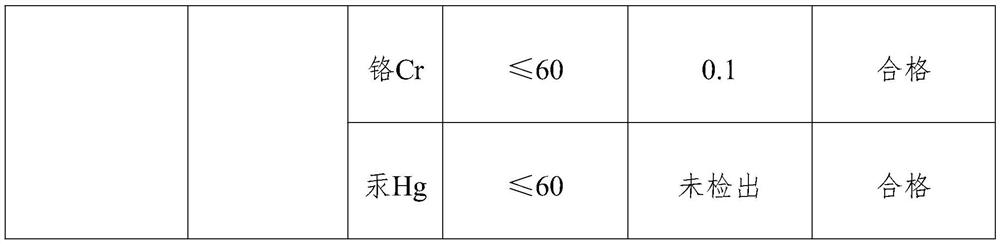

Examples

Embodiment 1

[0030] Add 230kg of deionized water into the dispersing tank, start stirring, and the stirring rate is 100 rpm; add 10kg of dispersant 5040, 5kg of PEG100, 5kg of AMP-95, and 3kg of defoamer NXZ into the dispersing tank, and confirm that they are completely dissolved Finally, add 40kg anatase nano titanium dioxide, 40kg rutile nano titanium dioxide, continue to stir for 30 minutes, add 150kg rutile titanium dioxide, 55kg kaolin, 55kg silica lime powder, 160kg heavy calcium, 55kg talcum powder, increase stirring Speed, stir at medium speed at 250 rpm for 30 minutes, then increase the stirring rate to 450 rpm, and stir at this high speed for 40 minutes.

[0031] After the stirring is finished, grind the stirred slurry with large steel balls with a diameter of 3 mm for 45 minutes to make the nanomolecules reach a diameter of about 20 nanometers, and then use medium-sized steel balls with a diameter of 2 mm to grind for 35 minutes to make the diameters of the nanomolecules reach ab...

Embodiment 2

[0034] Add 200kg of deionized water into the dispersing tank, start stirring at a rate of 80 rpm; add 7kg of dispersant 5040, 2.5kg of OP-40, 2kg of AMP-95, and 1kg of defoamer NXZ into the dispersing tank, After confirming that it is completely dissolved, add 40kg of anatase nano-titanium dioxide and 40kg of rutile nano-titanium dioxide. After stirring for 30 minutes, add 140kg of rutile-type titanium dioxide, 50kg of kaolin, 50kg of silica lime powder, 150kg of heavy calcium, and 50kg of talcum powder. , the particle size of heavy calcium and talcum powder is 1250 mesh, increase the stirring rate, first stir at 150 rpm for 30 minutes at a medium speed, then increase the stirring rate to 350 rpm, and stir at this high speed for 40 minutes.

[0035] After the stirring is finished, grind the stirred slurry with large steel balls with a diameter of 3 mm for 45 minutes to make the nanomolecules reach a diameter of about 20 nanometers, and then use medium-sized steel balls with a dia...

Embodiment 3

[0039] Add 215kg of deionized water into the dispersing tank, start stirring, and the stirring rate is 90 rpm; add 8kg of dispersant 5040, 4kg of PEG100, 3kg of AMP-95, and 2kg of defoamer NXZ into the dispersing tank, and confirm that they are all dissolved Finally, add 40kg anatase type nano-titanium dioxide, 40kg rutile type nano-titanium white, continue to stir for 30 minutes, add 145kg rutile type titanium dioxide, 53kg kaolin, 53kg silica lime powder, 155kg heavy calcium, 53kg talcum powder, increase stirring Speed, stir at medium speed at 200 rpm for 30 minutes, then increase the stirring rate to 400 rpm, and stir at this high speed for 40 minutes.

[0040] After the stirring is finished, grind the stirred slurry with large steel balls with a diameter of 3 mm for 45 minutes to make the nanomolecules reach a diameter of about 20 nanometers, and then use medium-sized steel balls with a diameter of 2 mm to grind for 35 minutes to make the diameters of the nanomolecules reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com