Green ecological inorganic mineral glue artificial stone for sculpture and preparation method thereof

An artificial stone and inorganic mineral technology, applied in the field of green ecological inorganic mineral glue material artificial stone, can solve the problems of marble can not be seamlessly spliced, dirt is easy to penetrate into it, coloring is easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

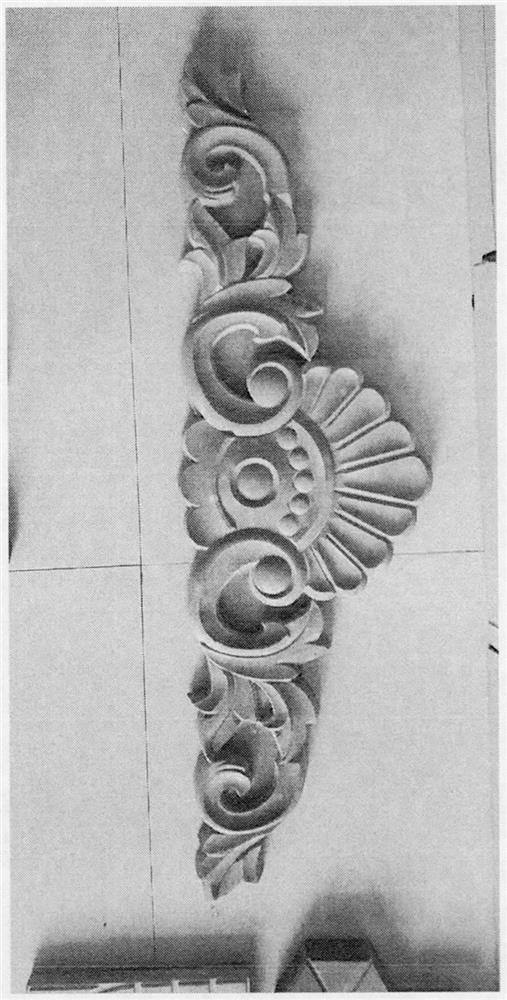

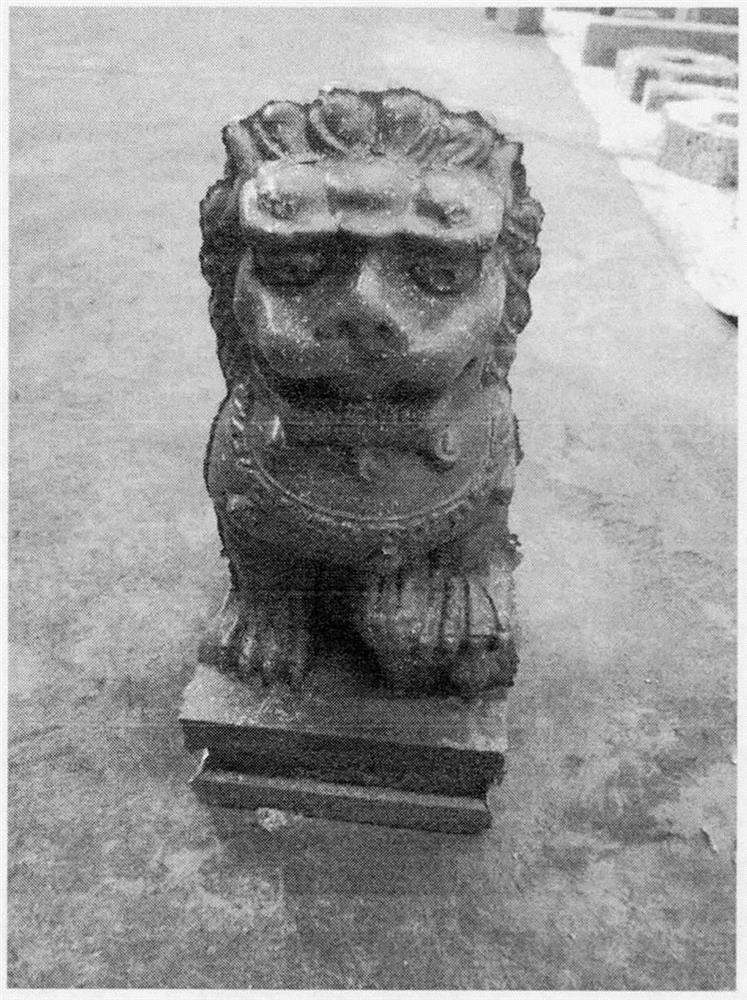

Image

Examples

Embodiment 1

[0051] First, weigh S95 mineral powder, 120 mesh iron tailings, and anti-cracking agent according to the ratio (weight ratio) of 1:2.2:0.04, then inject it into the forced mixer and mix for 3-5 minutes, and then inject it into the dry powder packaging bag through the dry powder packaging weighing scale .

[0052] Then put the water glass and water with a modulus of 1.5 into the high-speed disperser after weighing and measuring according to the weight ratio of 5.3:3.6, stir for 3-5 minutes, and then pour into the plastic packaging bag through the packaging weighing scale.

[0053] When sculpting, mix the dry powder and liquid material according to 1:0.275 (weight ratio). Manual stirring or manual electric mixer can be used for mixing. Can be sculpted as a plain material.

[0054] After mixing, the compressive strength of the material can reach more than 30MPa in 3 days. After 28 days, it can reach more than 70MPa. The number of freeze-thaw resistance is more than 500 times, a...

Embodiment 2

[0056] First, weigh S95 slag powder, 200-400 mesh gold tailings, anti-cracking agent, and iron oxide red pigment according to the ratio (weight ratio) of 1:2.3:0.035:0.05, then pour into the forced mixer and mix for 3-5 minutes, then Inject the dry powder packaging bag through the weighing scale of the dry powder packaging.

[0057]Then put the water glass and water with a modulus of 1.5 into the high-speed disperser after weighing and measuring according to the weight ratio of 5.3:4.0, stir for 3-5 minutes, and then pour into the plastic packaging bag through the packaging weighing scale.

[0058] When sculpting, mix the dry powder and liquid material according to 1:0.273 (weight ratio). Manual mixing or manual electric mixer can be used for mixing. Can be used as a red material for sculpture.

[0059] After mixing, the compressive strength of the material can reach more than 32MPa in 3 days. After 28 days, it can reach more than 65MPa. The number of freeze-thaw resistance ...

Embodiment 3

[0061] First, weigh S95 slag, 200 mesh gold tailings, and anti-cracking agent according to the ratio (weight ratio) of 1:2.3:0.045, then inject it into the forced mixer and mix it for 3-5 minutes, and then inject it into the dry powder package through the weighing scale of the dry powder package bag.

[0062] Then put the water glass and water with a modulus of 1.5 into the high-speed disperser after weighing and measuring according to the weight ratio of 5.3:3.8, stir for 3-5 minutes, and then pour into the plastic packaging bag through the packaging weighing scale.

[0063] During construction, mix the dry powder and liquid material according to 1:0.274 (weight ratio). Manual stirring or manual electric mixer can be used for mixing. It can be used as a repairing material to repair steles, statues and grottoes, and the repaired stone products can be seamlessly connected.

[0064] After mixing, the compressive strength of the material can reach more than 30MPa in 3 days. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com