Flux-covered welding wire and preparation method thereof

A coating and welding wire technology, which is applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of high degree of automation and the inability to simultaneously melt the "tube" shape of the end of the welding wire, etc., to achieve a high degree of automation and enhance the overall Effect of position weldability and no fill rate restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

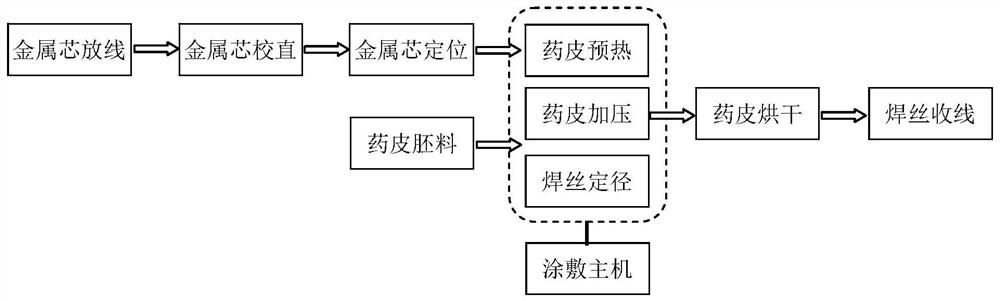

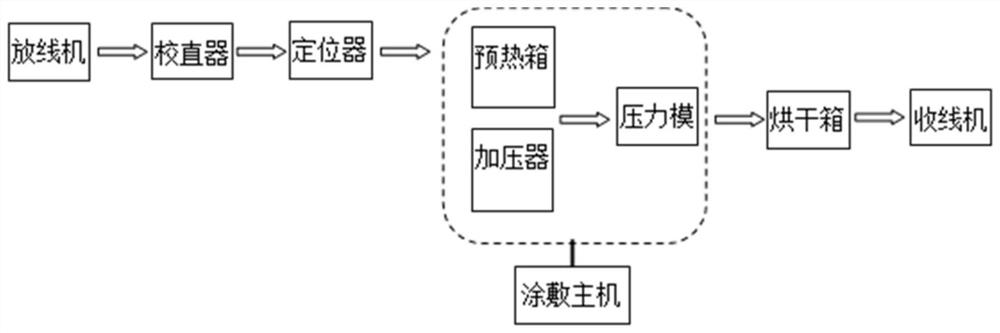

Method used

Image

Examples

Embodiment

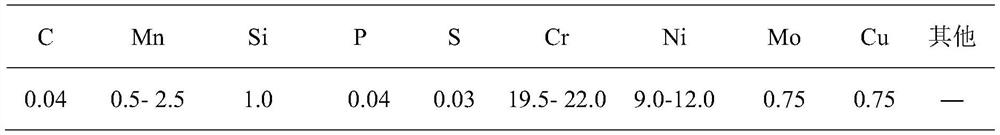

[0032] A coated welding wire, the welding wire is composed of a coating and a welding core, and the coating is wrapped around the outside of the welding core. The welding core is the metal core of the welding wire, which mainly plays the role of conducting current and filling metal during welding. The metal core is a solid wire. Compared with the alloy composition of the coated wire, the metal core can be a solid wire with similar or the same alloy composition, or a solid wire with a different alloy composition. The drug skin is a layer of drug skin containing slag-forming and gas-forming substances. The coating decomposes and melts during the welding process to form gas and slag, which can protect and improve the process performance. The composition of welding wire deposited metal alloy of the present invention is as follows:

[0033] Table 1 Welding wire deposited metal alloy composition (mass percentage)

[0034]

[0035] Others are Fe and other unavoidable impurity e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com