Welding process parameter optimization method suitable for different pipe diameters

A technology of welding process and optimization method, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complicated welding method specifications and various important parameters, and achieve the effect of ensuring stability and improving the forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Obtain various basic information of the pipeline to be welded, the basic information includes: pipeline material, wall thickness, welding process and groove shape, the welding pipeline with the same basic information adopts the following steps for all-position welding:

[0040] Step 1. Obtain the diameter D of the pipeline to be welded by moving the welding robot at a fixed distance;

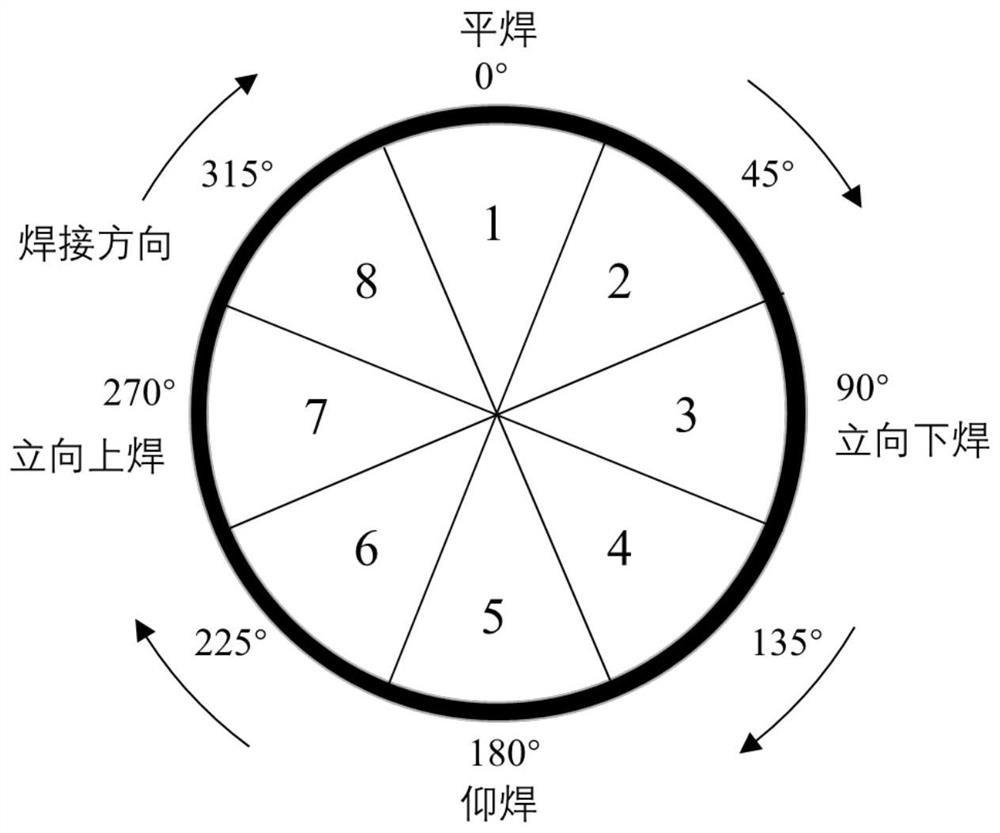

[0041] Step two, such as figure 1 As shown, the way to obtain the value of the pipe welding area is: divide the pipe into 8 equal parts, and the value of the equal part area corresponding to the flat welding of the pipe is 1, and the values are 2, 3, 4, 5, 6 in the clockwise direction , 7, 8. Collect the current crawling angle of the welding robot, and determine the value of the welding area of the pipeline according to the current crawling angle.

[0042]Step 3: Input the area value corresponding to the pipe diameter D and the current crawling angle of the welding robot into the p...

Embodiment 2

[0052] In the process of all-position welding, a welding process parameter optimization method suitable for different pipe diameters is adopted to control the action of the entire welding robot through a wireless remote control. After the welding robot starts running, it walks a certain distance, calculates and obtains the pipe diameter data, and sends it to the control module. The crawling angle detection module is built into the all-position welding robot to obtain the crawling angle α information of the welding robot in real time. The control module combines the above two data The welding process parameters are calculated by the welding process parameter optimization method adapting to different pipe diameters of the present invention, and sent to the execution module of the welding robot, and the welding robot receives and executes the instructions sent by the control module, so as to realize the automatic matching of process parameters in the whole welding process The pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com