Device and method for preparing circular pipes through high-deformation high strength alloy plates

A high-strength alloy, hard-to-deform technology, applied in the field of metal material processing, can solve the problems of unsolidified material processing technology, insufficient deformation, coarse microstructure, etc., to improve the forming effect, reduce the amount of springback, The effect of improving formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solution, implementation steps and advantages of the present invention more concretely understood, a detailed description will be given below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific implementations described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

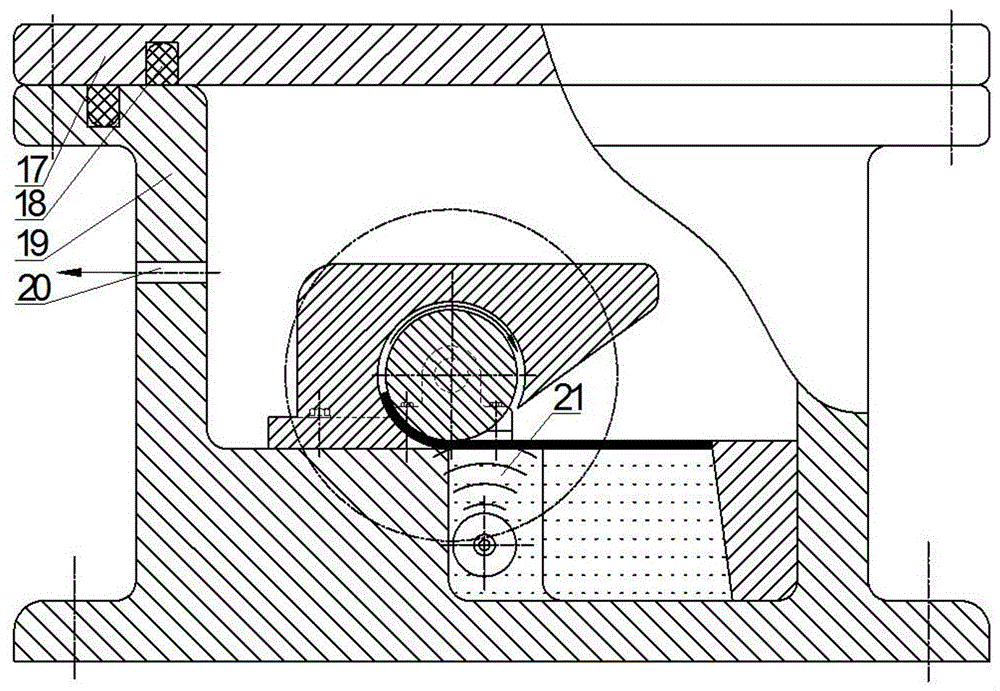

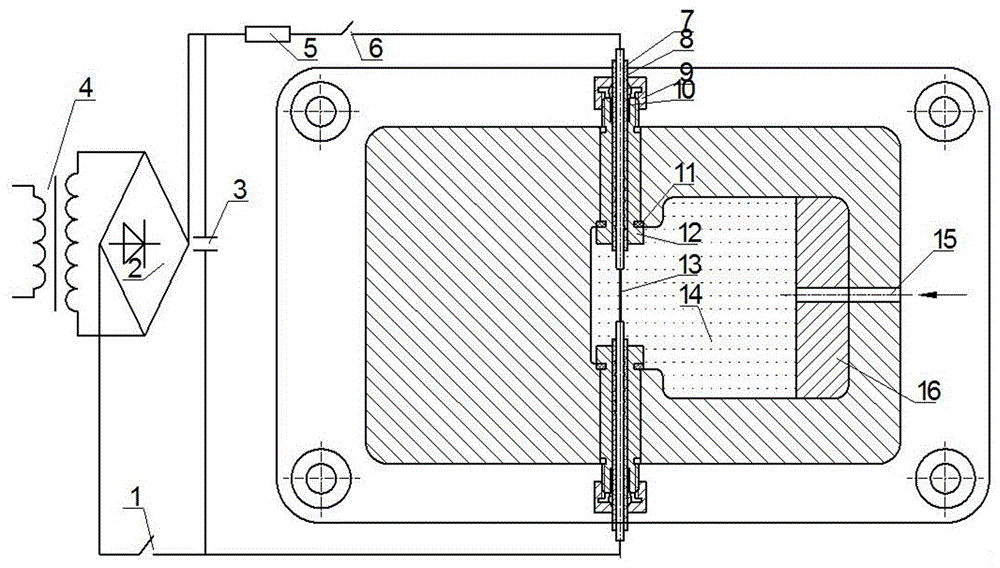

[0043] Such as Figure 1~Figure 6 As shown, a kind of device of the present invention prepares round pipe with the hard-to-deform high-strength alloy sheet material comprises water tank 19, and the water tank fixing plate 17 that is connected with water tank 19 upper ends, seals by second sealing rubber 18 between the two; Water tank 19 bottoms A wedge-shaped block 16 is installed; a boss is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com