A kind of conductive paint and its preparation method and application

A conductive coating and conductive carbon black technology, applied in conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor acid resistance, poor uniformity of the film layer, and weak bonding force of the substrate to achieve easy solution Ineffectiveness, less solid content, and the effect of reducing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

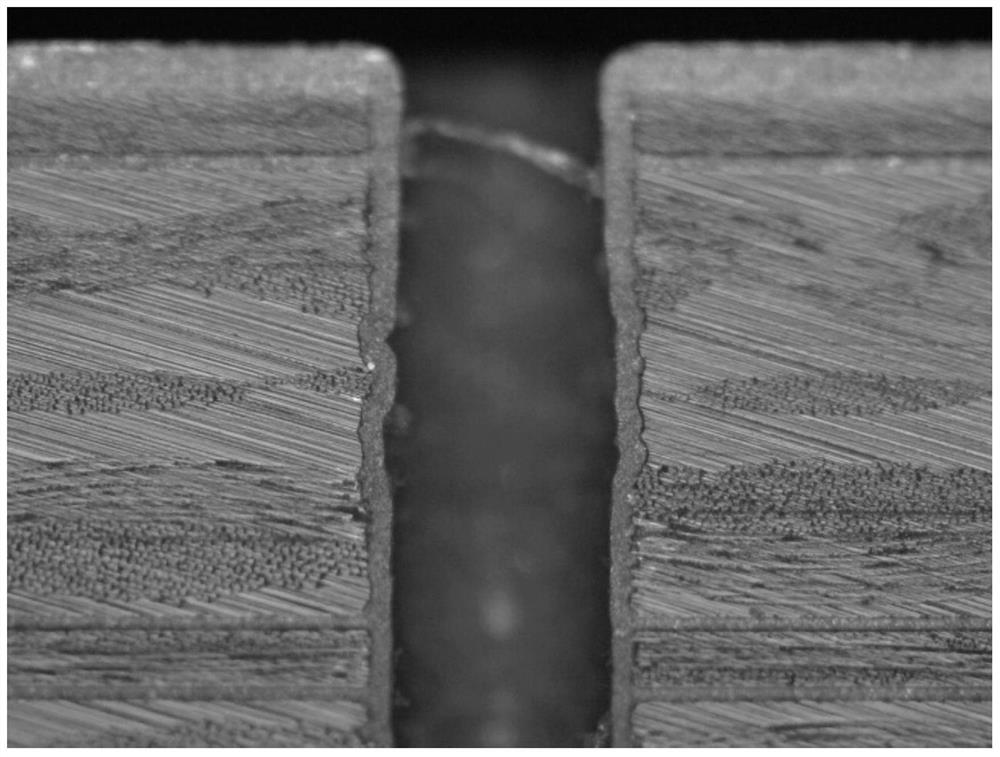

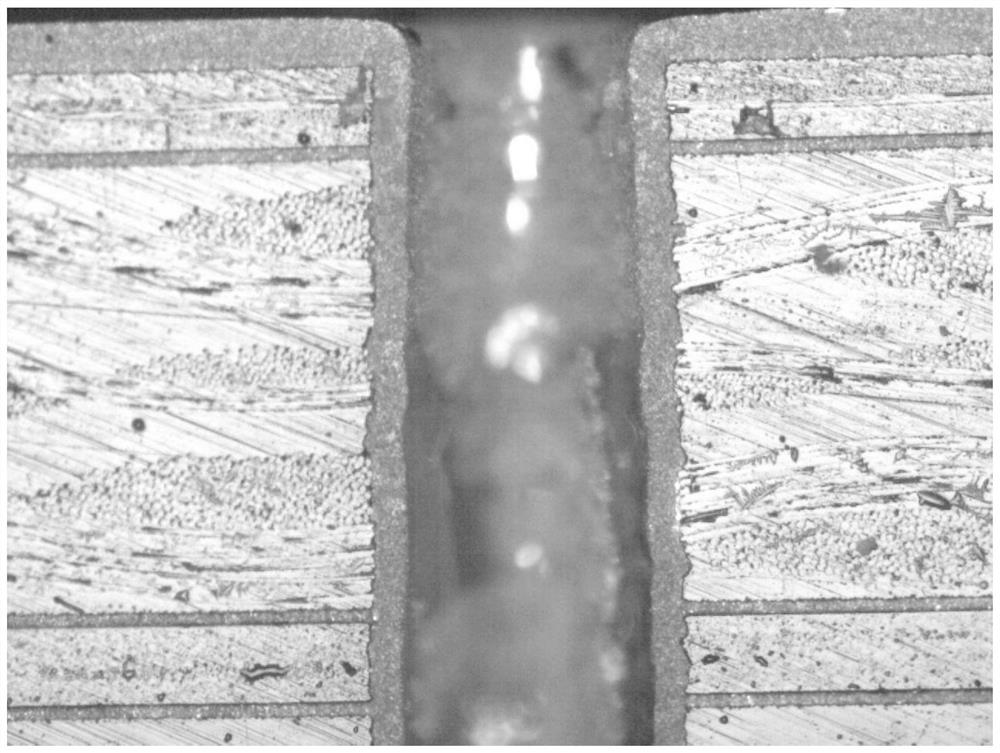

Image

Examples

Embodiment 1

[0054] A kind of conductive coating, in total weight 100 parts, comprises the raw material of following weight part: 0.5 part of conductive carbon black, 0.5 part of pigment carbon black, 0.15 part of pH buffering agent, 0.2 part of multifunctional additive, 1 part of sodium polycarboxylate dispersant, 0.6 part of alkylphenol polyoxyethyl ether dispersant, 0.1 part of potassium carbonate, 1.5 part of polystyrene sulfonic acid active agent, 0.1 part of defoamer, 0.01 part of antioxidant, 0.15 part of polyacrylic acid, and the rest The volume is deionized water.

[0055] The preparation method of the conductive paint is as follows: mixing the raw materials except the conductive auxiliary agent in proportion; then adding the conductive auxiliary agent to stir and disperse, and finally using a nanometer grinder to grind and disperse.

Embodiment 2

[0057] A kind of conductive paint, in total weight 100 parts, comprises the raw material of following weight part: 0.5 part of conductive carbon black, 0.5 part of pigment carbon black, 0.2 part of PH buffering agent, 0.2 part of multifunctional auxiliary agent, 0.5 part of sodium polycarboxylate dispersant, 1 part of alkylphenol polyoxyethyl ether dispersant, 1 part of polymethacrylic acid sodium salt dispersant, 0.1 part of potassium carbonate, 2 parts of polystyrene sulfonic acid active agent, 0.1 part of defoamer , 0.05 part of antioxidant, 0.03 part of polyacrylic acid, and the balance is deionized water.

[0058] The preparation method of the conductive coating in this embodiment is the same as the preparation method of Embodiment 1, and will not be described in detail here.

Embodiment 3

[0060] A kind of conductive coating, in total weight 100 parts, comprises the raw material of following weight part: 0.5 part of conductive carbon black, 0.5 part of pigment carbon black, 0.1 part of PH buffering agent, 0.1 part of multifunctional additive, 1 part of sodium polycarboxylate dispersant, 0.4 part of alkylphenol polyoxyethyl ether dispersant, 1 part of polymethacrylic acid sodium salt dispersant, 0.1 part of potassium carbonate, 1 part of polystyrene sulfonic acid active agent, 0.1 part of defoamer , 0.03 part of antioxidant, 0.03 part of polyurethane, and the balance is deionized water.

[0061] The preparation method of the conductive coating in this embodiment is the same as the preparation method of Embodiment 1, and will not be described in detail here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com