High-temperature retarder for well cementation and preparation method thereof

A retarder, high temperature technology, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems affecting the water loss performance of cement slurry, thermal dilution and sedimentation of the slurry, etc., and achieves weak dehydration effect at high temperature. , The effect of inhibiting cement hydration and excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

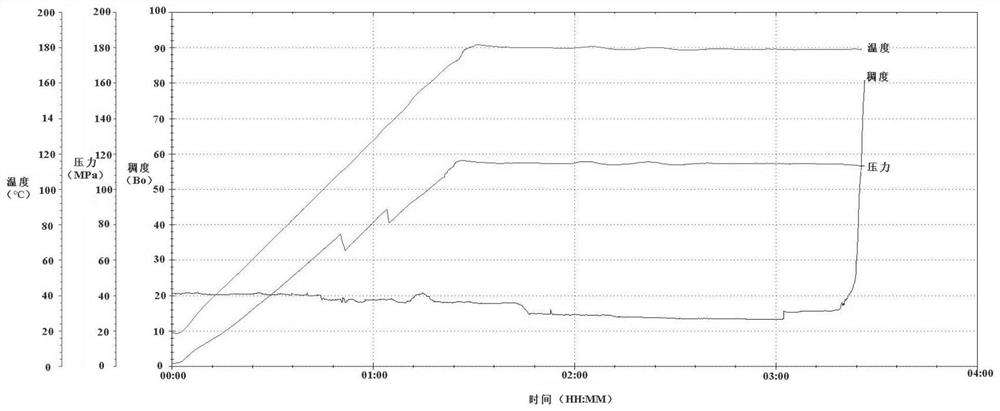

Image

Examples

preparation example Construction

[0036] A preparation method of high-temperature retarder for well cementing, comprising the following steps:

[0037] Step 1: Dissolving polymerized monomers in water to form solution A, adjusting the pH to 5.0-7.0;

[0038] Step 2: adding a molecular weight regulator to solution A in step 1 to form solution B;

[0039] Step 3: adding solution B in step 2 to initiator polymerization;

[0040] Step 4: Adjust the pH to 9.5-10.5, hydrolyze and cool down to obtain the required retarder.

[0041] The added mass of the molecular weight regulator accounts for 0.2-3.0%, preferably 0.8-2.0%, of the polymerized monomer mass; the added mass of the initiator accounts for 0.5-2.5%, preferably 0.8-1.2% of the polymerized monomer mass.

[0042] The polymerization temperature in step 3 is 50-70°C, and the polymerization time is 4-8h; the preferred polymerization temperature is 60-65°C, and the polymerization time is 5-6h; during the polymerization, keep the pH at 5.0-7.0. The hydrolysis te...

Embodiment 1

[0054] A preparation method of high-temperature retarder for well cementing, comprising the following steps:

[0055] Step 1: Dissolve 9.00 g of N,N-dimethylacrylamide, 9.00 g of sodium allylsulfonate, and 12.00 g of 3-allyloxy-1,2-propanediol in 260.00 g of deionized water. Adjust the pH of the system to 6.5.

[0056] Step 2: Add 0.6000g PEG200 and stir evenly, then transfer the solution to a 500mL three-necked flask;

[0057] Step 3: Warm up to 60°C under 100r / min stirring condition, dissolve 0.6000g ammonium persulfate with 10.00g deionized water; drop it into a three-necked flask within 2min, and continue to react at 60°C for 4h after the dropwise addition is completed.

[0058] Step 4: Adjust the pH to 10.0, raise the temperature to 90° C., continue stirring for 1 hour, and cool down to room temperature to prepare a retarder.

Embodiment 2

[0060] A preparation method of high-temperature retarder for well cementing, comprising the following steps:

[0061] Step 1: 6.00 g of N,N-dimethylacrylamide, 12.00 g of sodium methacrylate, and 12.00 g of 2-(allyloxy)ethanol were dissolved in 335.00 g of deionized water. Adjust the pH of the system to 5.0.

[0062] Step 2: Add 0.5001g PEG400 and stir evenly, then transfer the solution to a 500mL three-neck flask;

[0063] Step 3: Warm up to 50°C under stirring at 100r / min, and dissolve 0.4500g of ammonium persulfate in 10.00g of deionized water; drop it into a three-necked flask within 2min, and continue the reaction at 50°C for 6h after the addition is completed.

[0064] Step 4: adjust the pH to 9.5, raise the temperature to 85°C, continue to stir for 1 hour, and cool down to room temperature to prepare the retarder.

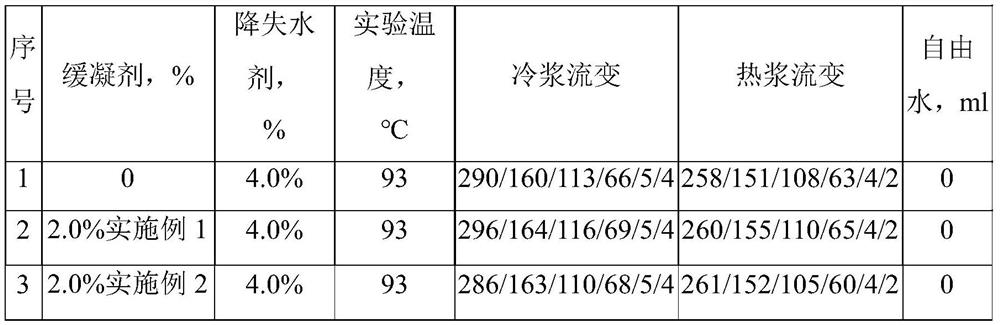

[0065] The effects of the retarder prepared in this example on rheology, water loss and strength were studied

[0066] The cement slurry was prepared acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com