Recycled concrete and preparation method thereof

A technology of recycled concrete and recycled gravel, applied in the field of building materials, can solve the problems of high freight costs, secondary environmental pollution, greenhouse effect, etc., and achieve the effects of fast setting time, high early strength and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

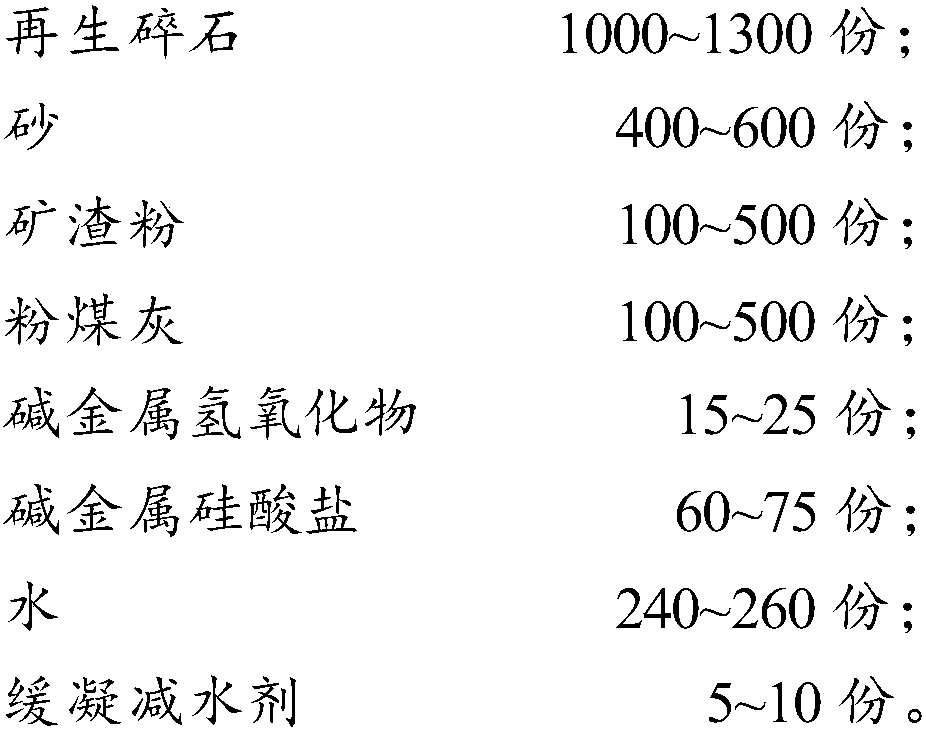

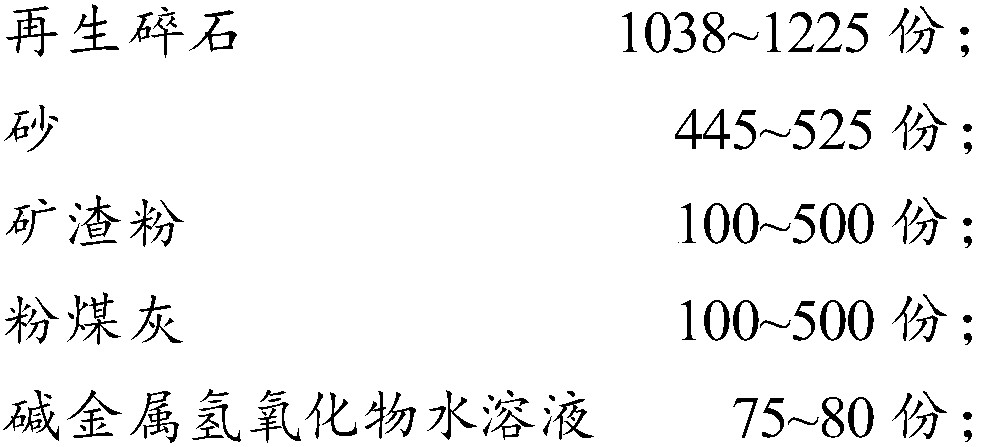

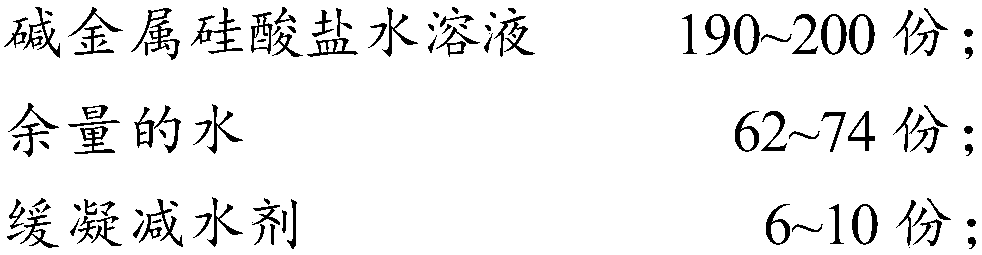

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing recycled concrete described in the above technical solution, comprising the following steps:

[0040] a), mixing recycled crushed stone, sand, slag powder, fly ash, alkali metal hydroxide, alkali metal silicate, water and retarding water reducer to obtain concrete slurry;

[0041] b), the concrete slurry is cured and cured to obtain recycled concrete.

[0042] In the preparation method provided by the present invention, at first each raw material component is mixed to prepare concrete slurry, and specific process comprises:

[0043] a1), mixing part of the water with alkali metal hydroxide and alkali metal silicate respectively to obtain an aqueous alkali metal hydroxide solution and an aqueous alkali metal silicate solution;

[0044] a2), mixing the regenerated crushed stone with the remaining amount of water to obtain the first mixture;

[0045] a3), mixing the first mixture with slag powder, fly ash and san...

Embodiment 1

[0068] Add 1155kg of continuously graded regenerated crushed stones with a particle size of 5-10mm and 10-20mm (mixed at a mass ratio of 1:1), 69.3kg of additional water, and stir for 5 minutes in a forced mixer; add 375kg of slag powder, powder 125kg of coal ash, 495kg of river sand, stirring for 5 minutes; adding 77.51kg of sodium hydroxide solution, 193.77kg of sodium silicate solution, 7.5kg of retarding superplasticizer, and stirring for 2 minutes to obtain concrete slurry 1.

[0069] Pour the slurry into a standard plastic mold and vibrate it compactly. On the first day, the ground is watered, and the mold filled with concrete slurry is placed on the ground, covered with a plastic film, and then watered on the plastic film, watered twice a day; Remove the formwork in two days, and immediately put the concrete specimen into the high-temperature steam rapid curing box after removing the formwork, the curing temperature is 80°C, and the curing time is 24h; Take it out and p...

Embodiment 2

[0071] Add 1225kg of regenerated crushed stones (mixed according to the mass ratio of 1:1) and 73.5kg of additional water into the forced mixer, and the mixing time is 5 minutes; add 300kg of slag powder, powder 100kg of coal ash, 525kg of river sand, stirring for 5 minutes; adding 77.51kg of sodium hydroxide solution, 193.77kg of sodium silicate solution, 6kg of retarding superplasticizer, and stirring for 2 minutes to obtain concrete slurry 2. The curing method refers to Example 1, and a slag-fly ash based geopolymer recycled concrete specimen of 150mm*150mm*150mm is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com