Filling material suitable for waste underground civil air defence hole treatment and preparation method thereof

A technology of filling material and underground man, which is applied in the field of underground engineering, can solve the problems of not paying attention to the filling rate and durability of filling materials, and not fully targeting, so as to achieve the effect of improving filling effect, improving activity and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

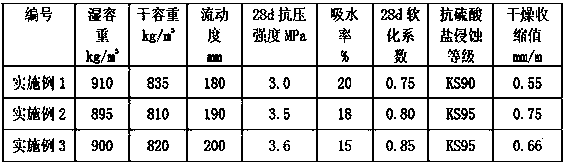

Embodiment 1

[0023] The filling material and its weight fractions for the treatment of abandoned underground man-made air defense tunnels provided in this embodiment are: 40 parts of cement, 35 parts of solid waste, 0.6 part of water-repellent agent, 0.1 part of plasticizer, 21.5 parts of water, foaming agent 0.05 parts.

[0024] Above-mentioned cement is P.O 42.5 ordinary portland cement;

[0025] The above-mentioned solid waste is the result of sintering desulfurization ash discharged from the iron and steel industry after being ground by a ball mill, and the passing rate of 200 mesh is greater than 95%;

[0026] Above-mentioned living hydrophobic agent is commercially available calcium stearate, is white powder;

[0027] The above plasticizer is a polycarboxylate water reducer with a solid content of 40% and a water reducing rate greater than 25%;

[0028] Above-mentioned foaming agent is commercially available composite foaming agent.

[0029] The preparation method of the waste und...

Embodiment 2

[0034] Same as above-mentioned Example 1, the difference is that the filling material and its weight fraction are: 60 parts of cement, 15 parts of solid waste, 1.5 parts of water-repellent agent, 0.2 part of plasticizer, 26.5 parts of water, and 0.2 part of foaming agent. Among them, the solid waste is obtained after the undisturbed stone powder discharged from the machine-made sand and gravel industry is ground by a ball mill, and the pass rate of 200 mesh is greater than 95%.

[0035] The composition of the foaming solution in step (2) of the preparation method is as follows: 1.5 parts by weight of water and 0.2 parts of foaming agent are uniformly mixed to form a foaming solution.

Embodiment 3

[0037] Same as the above-mentioned Example 1, the difference is that the filling materials and their weight fractions are: 50 parts of cement, 30 parts of solid waste, 2 parts of water-repellent agent, 0.3 part of plasticizer, 36.5 parts of water, and 0.5 part of foaming agent. Among them, solid waste is the result of sintering desulfurization ash discharged from the iron and steel industry and tuff undisturbed stone powder discharged from the machine-made sand and gravel industry in a ratio of 1:1 by weight and then ground by a ball mill. The passing rate of 200 mesh is greater than 95%;

[0038] The composition of the foaming solution in step (2) of the preparation method is as follows: 1.5 parts by weight of water and 0.3 parts of foaming agent are uniformly mixed to form a foaming solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com