Antibacterial organic glass plate and preparation method thereof

A technology for plexiglass and plates, which is applied in the field of antibacterial plexiglass plates and its preparation, and can solve the problems of low sterilization efficiency of plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

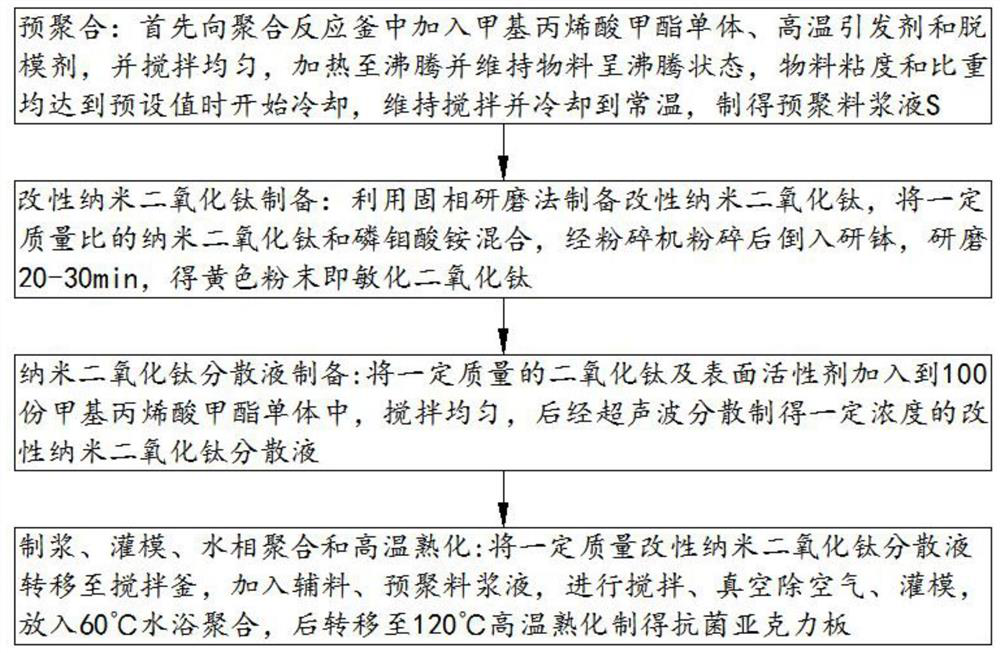

Method used

Image

Examples

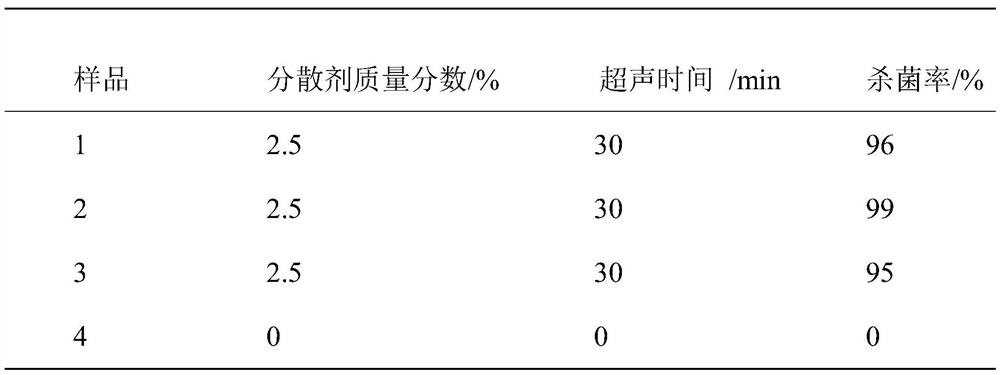

Embodiment 1

[0037] Add 7.5kg of methyl methacrylate monomer into the polymerization reactor, add 1.5g of azobisisobutyronitrile as an initiator, add an appropriate amount of release agent, stir evenly, heat to boiling, the material viscosity reaches about 60s, stop Heat and cool with cooling water, stir and cool to 30°C to prepare a slurry. Take 2.5kg of methyl methacrylate monomer, add 250g of modified nano titanium dioxide and 300g of 731A into the methyl methacrylate monomer, and after ultrasonic dispersion, pour it into the prepolymer, transfer it to a stirring tank, and add 1kg of o-phthalic acid Dibutyl diformate, an appropriate amount of low-temperature initiator and mold release agent, stir evenly, vacuumize and remove air, pour into a silicon glass mold, and discharge air bubbles. Pour the measured material into the silicon glass mold, discharge the air bubbles, and clamp the mold with spring clips. Place the mold filled with material in a water bath, maintain the temperature of...

Embodiment 2

[0039] Add 7.5kg of methyl methacrylate monomer into the polymerization reactor, add 1.5g of azobisisobutyronitrile as an initiator, add an appropriate amount of release agent, stir evenly, heat to boiling, the material viscosity reaches about 60s, stop Heat and cool with cooling water, stir and cool to 30°C to prepare a slurry. Take 2.5kg of methyl methacrylate monomer and add 250g of modified titanium dioxide and 300g of Tween-80 (sorbitan oleate, polysorbate-80) into methyl methacrylate monomer, after ultrasonic dispersion Pour it into the prepolymer, transfer it to a stirring tank, add 1kg of dibutyl phthalate, an appropriate amount of low-temperature initiator and a release agent, stir evenly, vacuumize and remove the air, and pour it into a silicon glass mold to remove air bubbles. Pour the measured material into the silicon glass mold, discharge the air bubbles, and clamp the mold with spring clips. Place the mold filled with material in a water bath, maintain the temp...

Embodiment 3

[0041]Add 7.5kg of methyl methacrylate monomer into the polymerization reactor, add 1.5g of azobisisobutyronitrile as an initiator, add an appropriate amount of release agent, stir evenly, heat to boiling, the material viscosity reaches about 60s, stop Heat and cool with cooling water, stir and cool to 30°C to prepare a slurry. Take 2.5kg of methyl methacrylate monomer, add 250g of modified titanium dioxide and 300g of Tritonx-100 (tertoctylphenol polyoxyethylene ether) into the methyl methacrylate monomer, and pour it into the prepolymer after ultrasonic dispersion , transferred to a stirred tank, added 1kg of dibutyl phthalate, appropriate amount of low-temperature initiator and release agent, stirred evenly, vacuumed to remove air, poured into a silicon glass mold, and discharged air bubbles. Pour the measured material into the silicon glass mold, discharge the air bubbles, and clamp the mold with spring clips. Place the mold filled with material in a water bath, maintain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com