Diamond grinding wheel with orderly arranged crystal-oriented abrasives

A diamond grinding wheel and crystal orientation technology, applied in the field of diamond grinding wheels, can solve the problems of reduced grinding efficiency, low edge height of diamond grinding layer, diamond abrasive grain strength, crystal shape damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

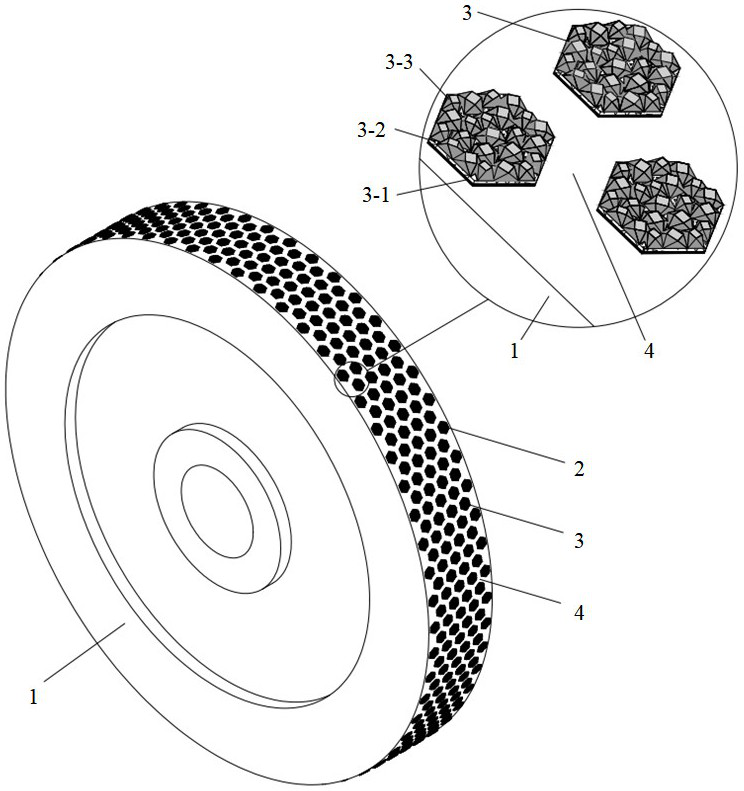

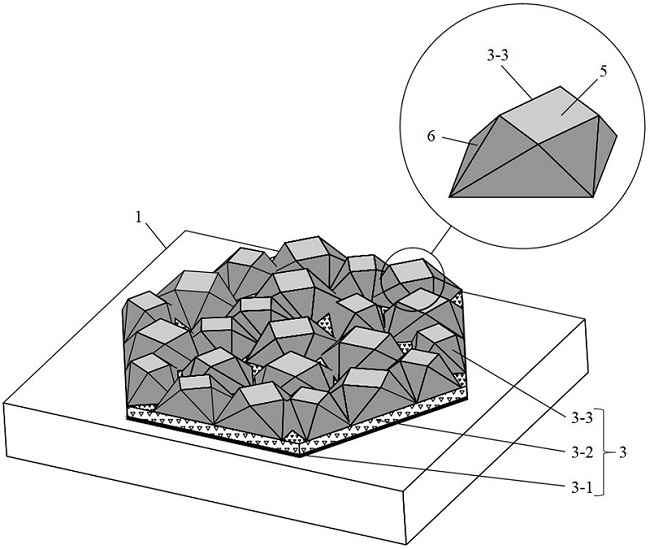

[0020] A diamond grinding wheel with crystal oriented abrasives arranged in order is characterized in that the grinding wheel comprises a matrix 1 and an abrasive layer 2 . The base body 1 is made of titanium alloy with a diameter of Φ100 mm and a thickness of 10 mm. The abrasive layer 2 is composed of a large number of honeycomb micro-grinding units 3 and a large number of intersecting micro-channels 4 . The micro-grinding unit 3 is composed of amorphous carbon 3-1, a diamond bonding layer 3-2 and a plurality of crystal-oriented diamond abrasive grains 3-3.

[0021] The thickness of amorphous carbon 3-1 is only tens of nanometers, and it is used to enable {100} crystal plane 5 and {111} crystal plane 6 to be oriented as the top surface and side surface of diamond abrasive grain 3-3 after sufficient diffusion .

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com