Branched antibacterial polyamino acid and its preparation method and application

A polyamino acid, polylysine technology, applied in the field of medicine, can solve the problems of limitation, increase in charge density, hinder the development of antibacterial peptides or polymers, etc., and achieve the effect of improving antibacterial activity, good antibacterial activity, and avoiding toxic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method of branching an antibacterial polyamino acid, comprising a liquid phase synthesis method (an amino acid N-carboxy-cycloic anhydride (NCA) open loop polymerization method), solid phase synthesis method. The branched antibacterial polyamino acid synthesized by liquid phase synthesis (N-carboxy-cycloal acid anhydride open loop polymerization), has simple operation, high yield, low production cost, no spinning phenomenon, easy to obtain polymer polyamino acid Multiple advantages, but the synthesized polymer molecular weight distribution is relatively wide. The sequence and molecular weight of the polypeptide can be accurately controlled by solid phase synthesis method, but the synthesis time is long, high cost, and the sequence of direct synthesis is short. Therefore, although the antibacterial polyamino acid synthesized by two methods, it has the characteristics of avoiding toxic effects, less susceptible to hemolysis, high safety, ...

Embodiment 1

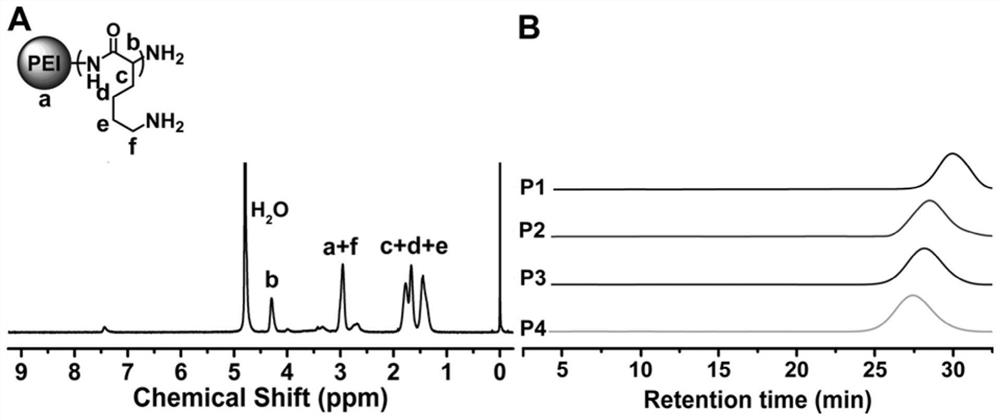

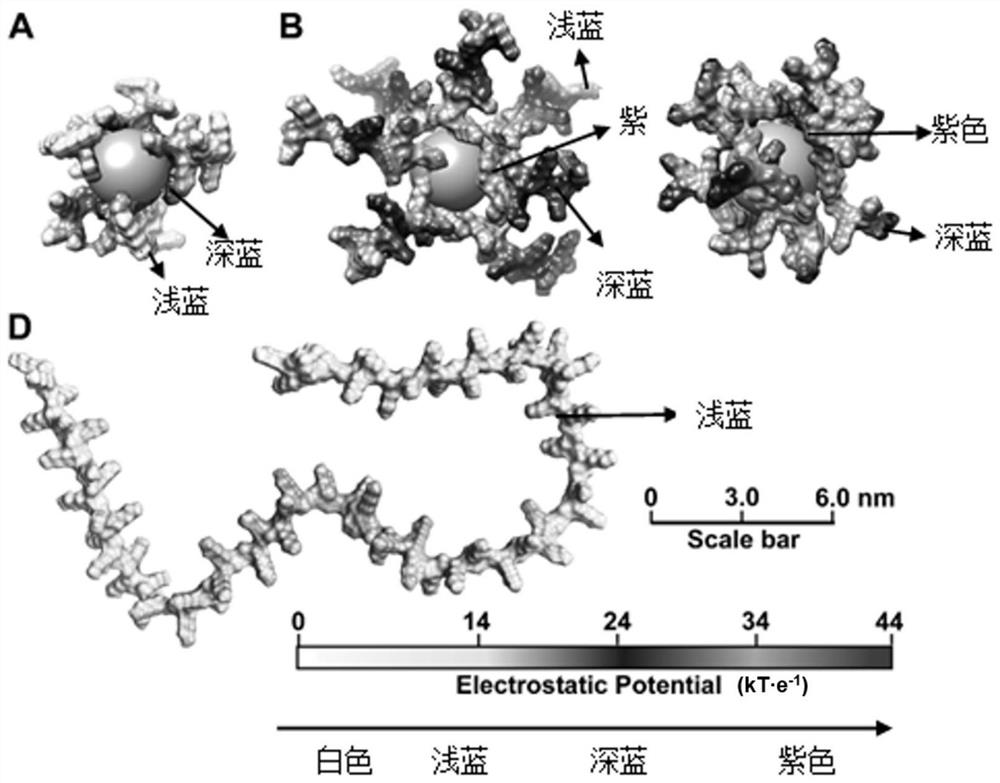

[0056] Example 1 Liquid phase synthesis method of star PLL antibacterial polyamino acid (PEI-G-PLL) (an amino acid N-carboxy-cycloal acid anhydride open loop poly)

[0057] 1. Synthesis of Star Poly L-lysine (PLL)

[0058] (1) Synthesis of amino acid N-carboxy-cycloalic anhydride (NCA)

[0059] Weigh ε-benzyloxycarbonyl-L-ε-benzoxycarbonyl-L-lysine, activated carbon, and triam (BTC) add anhydrous acetate (EA) to heat reflux, filtration, and obtain filtrate containing NCA crude product, the reaction route is as follows:

[0060]

[0061] The filtrate was frozen to -18 ° C or lower, and the saturated sodium hydrogencarbonate solution of 4 ° C was carried out with a saturated sodium hydrogen sodium hydrogen carbonate solution, respectively, and the residual hydrochloric acid and three light gas were removed. Finally, the product passes through crystallization and recrystallization processes in a compound of ethyl acetate-petroleum ether to obtain high purity NCA.

[0062] (2) Synth...

Embodiment 2

[0071] Example 2 Solid phase synthesis method of star PLL antibacterial polyamino acid

[0072] 1, synthesis of star PLL

[0073] (1) Synthesis of dendritic PLL kernel

[0074] DMF solution containing 20% piperidine is removed from the FMOC protective group of Rink Amide-Mbha Resin resin, added to N, N'-bisflyfluorene methoxycarbonyl-lysine (Fmoc-Lys (FMOC) -OH) The coupling reaction is carried out by DMF as a solvent, 1-hydroxybenzene triazole (HOBT), and N, N'-diisopropyl carbon diimide (DIC) for condensants, and then with DMF containing 20% piperidine The solution was removed from the FMOC protecting group to give a generation of dendritic L-lysine. Then by repeated coupling and deprotection process, a second-generation dendrim-shaped PLL having four amino groups and a three-generation dendrimal PLL having 8 amino groups is obtained as the core of the star PLL, and the joint route is as follows:

[0075]

[0076] Synthesis and Characterization of (2) of the star-PLL

[0077...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com