Preparation method of polylactic acid cooling modified tow filter stick

A technology of polylactic acid and polylactic acid masterbatch, which is applied in the fields of e-liquid filter elements, applications, tobacco, etc., and can solve problems such as low glass transition temperature and melting point, melting, and no filter section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation method of polylactic acid cooling modified tow filter rod

[0023] The polylactic acid cooling modified tow filter rod is composed of 60 parts by weight of polylactic acid masterbatch, 15 parts by weight of SEBS and 8 parts by weight of PP in a blender and mixed uniformly for 6 minutes. The on-line melt polymerization reaction is extruded by screw screw at a temperature of 185℃. Extrusion, the screw speed is 55r / min, cooling for 2h at 10℃, after entering the melt spinning process, the draft ratio is 2 times, the spinning speed is 1000m / min, the crimping temperature is 85℃, drying at 65℃ After setting for 17 minutes, the tow is finally cooled and solidified at 20±2℃ to obtain the polylactic acid tow, and the filter rod is formed on a conventional filter rod machine.

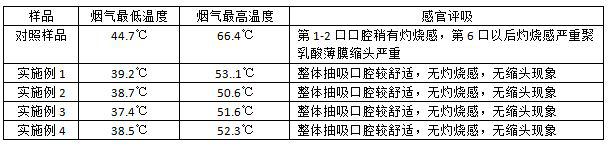

[0024] The polylactic acid cooling modified material prepared in this example was substituted for the Philip Morris International heat-not-burn cigarette cooling section, and smoking was s...

Embodiment 2

[0025] Example 2: Preparation method of polylactic acid cooling modified tow filter rod

[0026] The polylactic acid cooling modified tow filter rod is composed of 65 parts by weight of polylactic acid masterbatch, 18 parts by weight of SEBS and 4 parts by weight of PP in a blender and mixed uniformly for 5 minutes, at 178°C, the on-line melt polymerization reaction is extruded by screw screw. Extrusion, screw speed 60r / min, cooling for 2h in 10℃ environment, after entering the melt spinning process, draft ratio is 3 times, spinning speed 1200m / min, crimp molding temperature 65℃, drying at 72℃ After shaping for 18 minutes, the tow is cooled and solidified and shaped at 20±2℃ to obtain the polylactic acid tow, and the filter rod is formed on a conventional filter rod machine.

[0027] The polylactic acid cooling modified material prepared in this example was substituted for the Philip Morris International heat-not-burn cigarette cooling section, and smoking was simulated according t...

Embodiment 3

[0028] Example 3: Preparation method of polylactic acid cooling modified tow filter rod

[0029] The polylactic acid cooling modified tow filter rod is composed of 68 parts by weight of polylactic acid masterbatch, 16 parts by weight of SEBS and 7 parts by weight of PP in a blender and mixed uniformly for 8 minutes, and the on-line melt polymerization reaction is extruded by screw screw at 192℃. Extrusion, screw speed 45r / min, cooling for 1h in 8℃ environment, after entering the melt spinning process, the draft ratio is 1 times, spinning speed 800m / min, crimp forming temperature 72℃, drying at 68℃ After shaping for 20 minutes, the tow is cooled and solidified and shaped at 20±2°C to obtain the polylactic acid tow, and the filter rod is formed on a conventional filter rod machine.

[0030] The polylactic acid cooling modified material prepared in this example was substituted for the Philip Morris International heat-not-burn cigarette cooling section, and smoking was simulated accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com