Vegetable oil acid modified epoxy acrylate light-cured resin and preparation method thereof

A technology of epoxy acrylate and light-curing resin, applied in epoxy resin coatings, coatings, etc., can solve the problems of limited application scope, decreased strength of epoxy resin cured film, low cross-linking density, etc., to achieve performance Excellent, reduced viscosity, improved brittleness problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

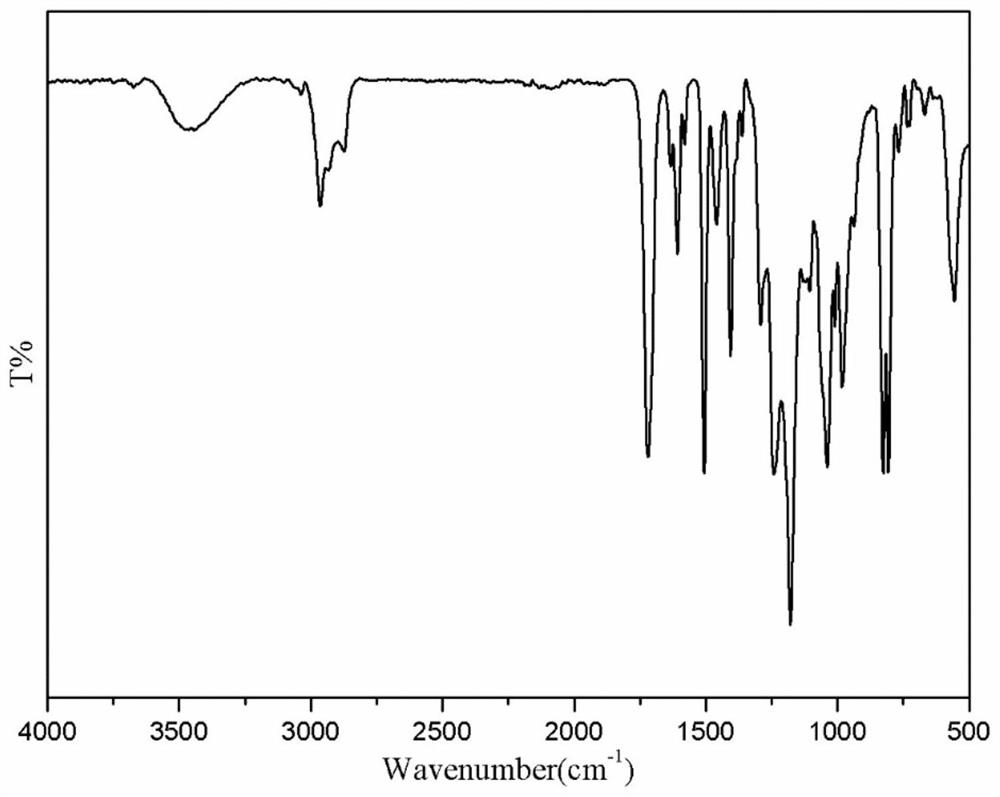

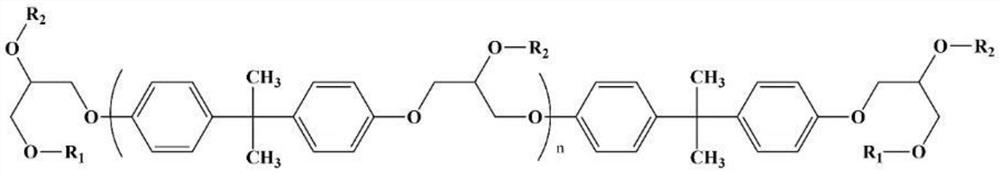

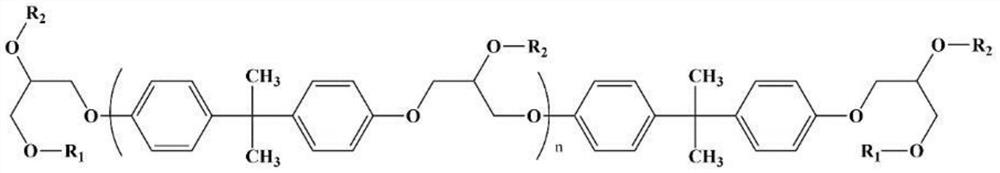

Image

Examples

Embodiment 1

[0028] Weigh 100g of epoxy resin E51 in a three-necked flask, add 72g of oleic acid, add 1.0g of tetrabutylammonium bromide, and pass N 2 , stirred and heated to 100°C. After reacting for 2 hours, test the acid value, and when the acid value is less than 10mgKOH / g, lower the temperature to 90°C. After the temperature stabilized, 18.4 g of acrylic acid in which 500 ppm of p-hydroxyanisole was dissolved was added dropwise. React until the acid value of the system is less than 10mgKOH / g. Maintain the temperature at 90°C, add 15.0 g of refined maleic anhydride to the reaction system, and react for 1 hour to test the acid value. When the acid value difference was measured twice and was less than 5mgKOH / g, 0.02g of p-hydroxyanisole, 1.0g of tetrabutylammonium bromide were added to the system, and then 21.7g of glycidyl methacrylate (GMA) was added dropwise, React at a constant temperature of 100°C until the acid value is less than 10mgKOH / g, then stop heating. When the temperatu...

Embodiment 2

[0030] Weigh 100 g of epoxy resin E51 into a three-necked flask, add 72 g of linoleic acid, and add 1.0 g of tetrabutylammonium bromide. Pass N 2 , stirred and heated to 100°C. After reacting for 2 hours, test the acid value, and when the acid value is less than 10mgKOH / g, lower the temperature to 90°C. After the temperature stabilized, 18.4 g of acrylic acid in which 500 ppm of p-hydroxyanisole was dissolved was added dropwise. React until the acid value of the system is less than 10mgKOH / g. Maintain the temperature at 90°C, add 15.0 g of refined maleic anhydride to the reaction system, and react for 1 hour to test the acid value. When the difference in acid value is less than 5mgKOH / g, add 0.02g p-hydroxyanisole and 1.0g tetramethylammonium chloride to the system, then add 21.7g glycidyl methacrylate (GMA) dropwise, React at a constant temperature of 110°C until the acid value is less than 10mgKOH / g, then stop heating. When the temperature cooled to 80°C, the resin was ...

Embodiment 3

[0032] Weigh 100 g of epoxy resin E51 into a three-necked flask, add 72 g of linolenic acid, and add 1.0 g of tetrabutylammonium bromide. Pass N 2 , stirred and heated to 100°C. After reacting for 2 hours, test the acid value, and when the acid value is less than 10mgKOH / g, lower the temperature to 90°C. After the temperature stabilized, 18.4 g of acrylic acid in which 500 ppm of p-hydroxyanisole was dissolved was added dropwise. React until the acid value of the system is less than 10mgKOH / g. Maintain the temperature at 90°C, add 15.0 g of refined maleic anhydride to the reaction system, and react for 1 hour to test the acid value. When the acid value difference was measured twice and was less than 5mgKOH / g, 0.02g of p-hydroxyanisole, 1.0g of tetrabutylammonium bromide were added to the system, and then 21.7g of glycidyl methacrylate (GMA) was added dropwise, React at a constant temperature of 115°C until the acid value is less than 10mgKOH / g, then stop heating. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com