Guide plate functional surface imitating Laval nozzle structure and manufacturing method thereof

A manufacturing method and deflector technology, which are applied to special surfaces, devices for coating liquid on surfaces, space vehicle propulsion system devices, etc., can solve the lack of surface function development, restrict plate surface tension, spacecraft power failure, loss Service ability and other issues, to achieve the effect of optimizing propellant management capability, improving propellant utilization rate, and improving diversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

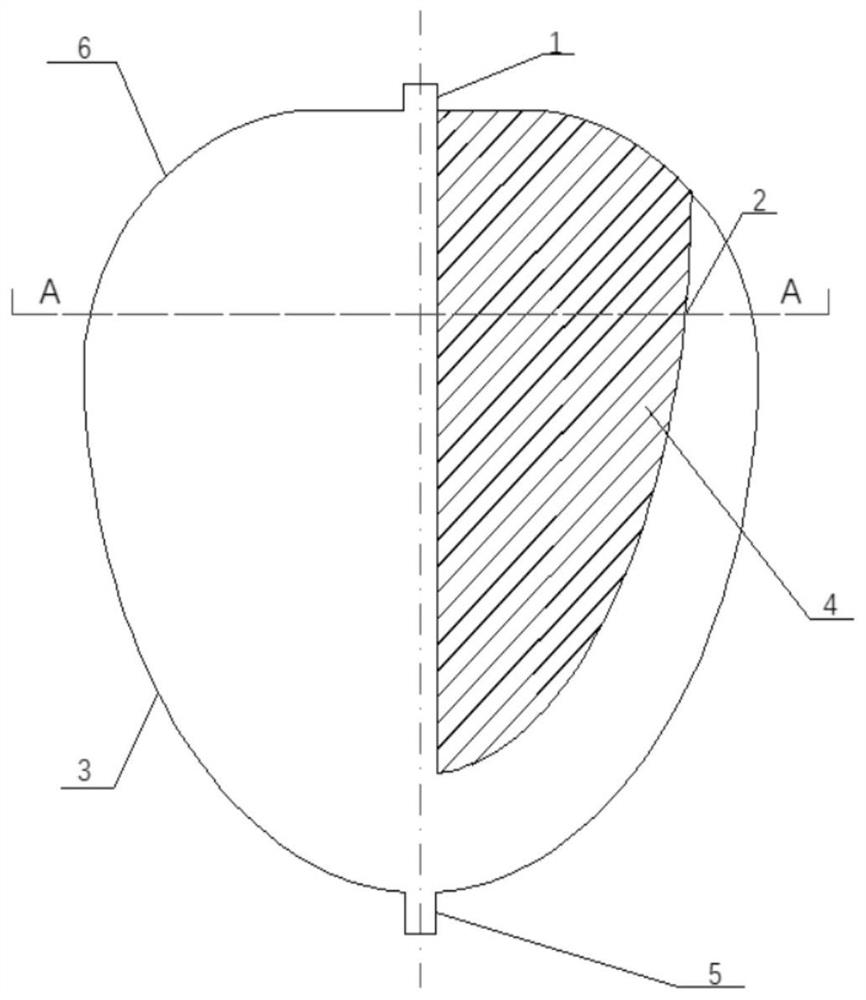

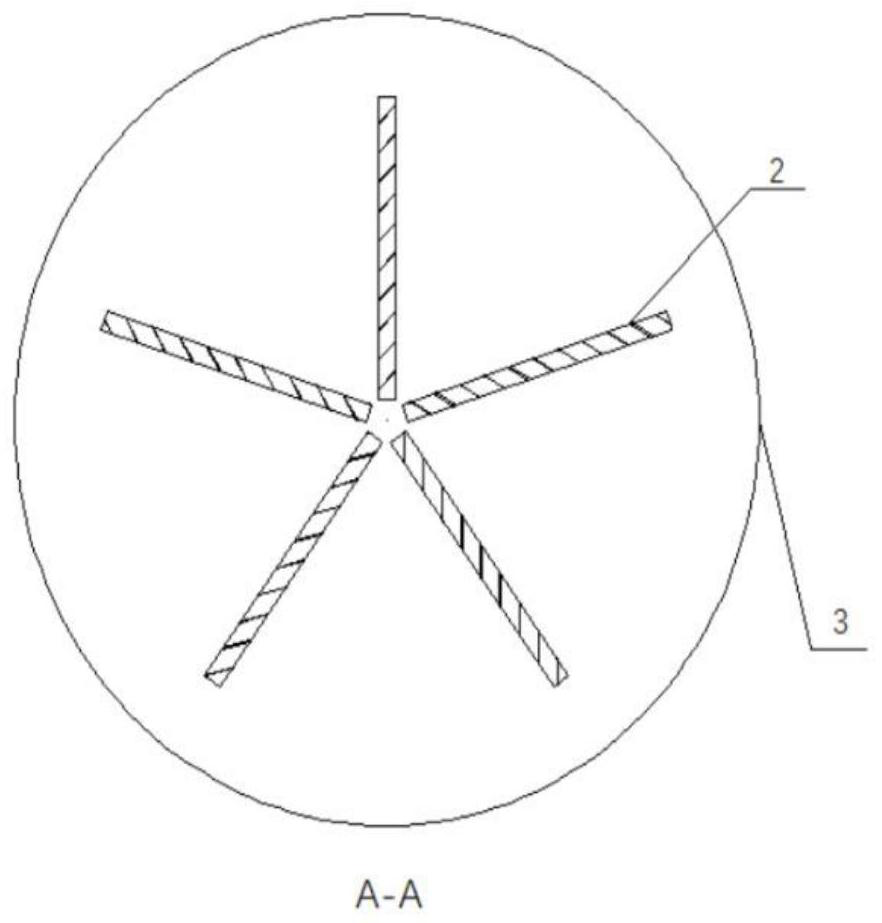

[0033] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0034] This invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In the drawings, components are exaggerated for clarity.

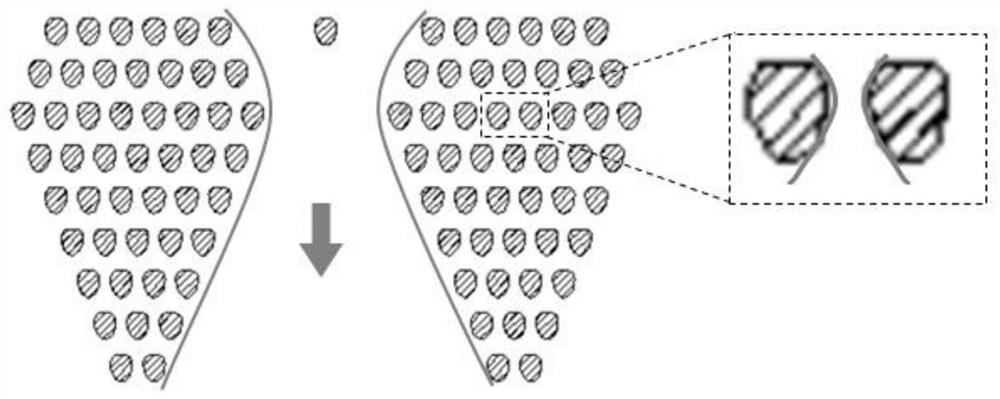

[0035] The invention discloses a functional surface of a flow deflector imitating a Laval nozzle structure, which comprises the surface of the flow deflector and several uniformly arranged guide arrays on the surface of the flow deflector;

[0036] The surface of the deflector is a super-hydrophilic surface;

[0037] The guide array comprises a number of uniformly arranged structural units whose surface is a superhydrophobic surface;

[0038] The surface of the deflector between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| Area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com