Antibacterial antiviral stainless steel and preparing method thereof

A stainless steel, anti-virus technology, applied in botanical equipment and methods, disinfectants, fungicides, etc., can solve problems such as only preventing the infection of specific viruses, restricting the use environment of stainless steel workbenches, and being unsuitable for large-scale promotion. Achieving good antibacterial and antiviral properties, durable antibacterial and antiviral properties, and beneficial to large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

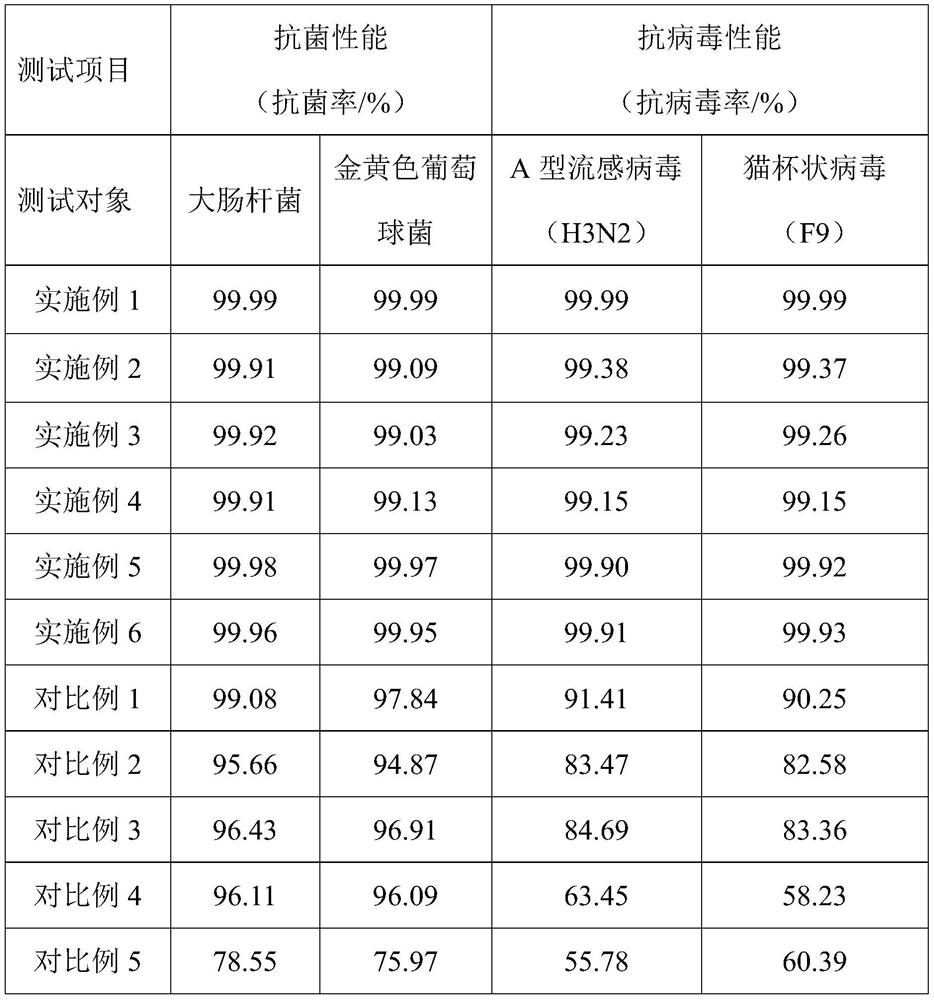

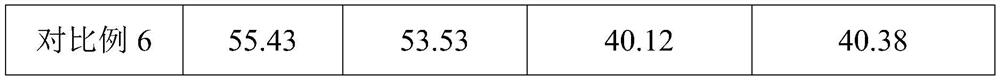

Examples

preparation example Construction

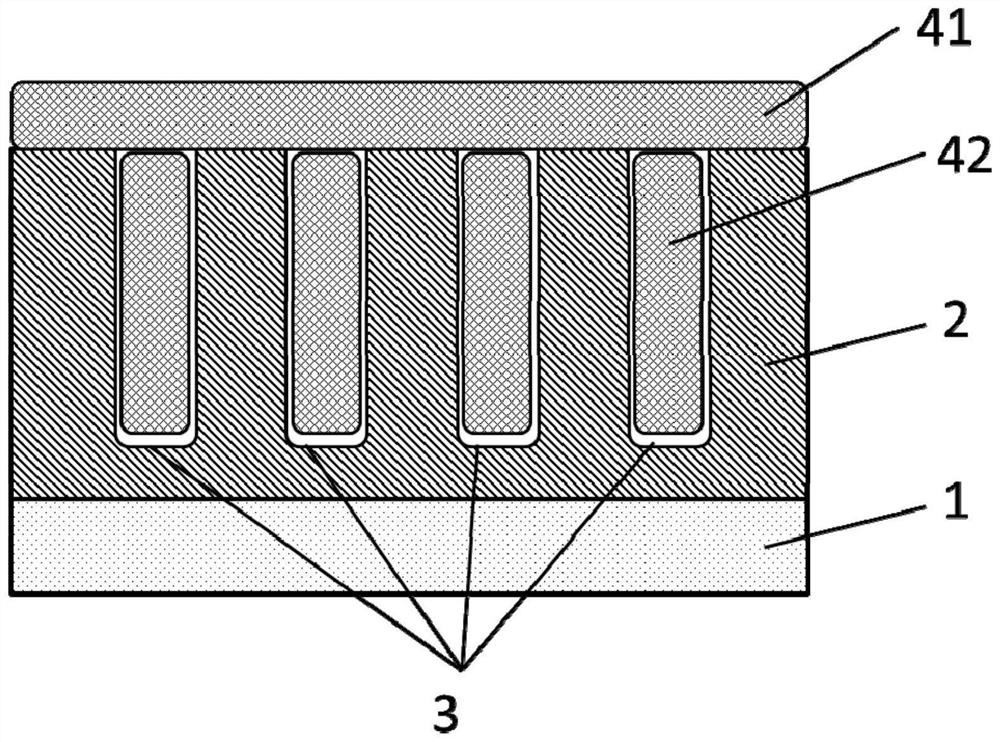

[0070] The preparation method of antibacterial and antiviral stainless steel of the present invention comprises the steps:

[0071] (1) stainless steel is anodized, and an anodized film with micropores is formed on the surface of the stainless steel;

[0072] (2) Soak the stainless steel obtained by anodizing described in step (1) in sol A, then take out the soaked stainless steel and heat it once to obtain the antibacterial and antiviral stainless steel crude product;

[0073] (3) Soak the antibacterial and antiviral stainless steel crude product described in step (2) in sol B, then take out the soaked stainless steel and carry out secondary heating to obtain antibacterial and antiviral stainless steel;

[0074] Wherein, the sol A includes butyl titanate, and the sol B includes valacyclovir hydrochloride and acyclovir.

[0075] Typical but non-limiting examples of the invention are as follows:

Embodiment 1

[0077] The present embodiment provides a kind of preparation method of antibacterial and antiviral stainless steel, and described preparation method comprises the following steps:

[0078] (1) Carry out mechanical polishing, chemical degreasing and electrochemical polishing to stainless steel successively as pretreatment, then carry out anodic oxidation in acidic oxidation solution, form the anodic oxidation film with micropore on the surface of described stainless steel;

[0079] Wherein, the mechanical polishing is to use sandpaper for surface grinding, from 400 mesh to 3000 mesh, and the chemical degreasing is carried out using a degreasing liquid, the composition of the degreasing liquid includes sodium hydroxide 45g / L, sodium carbonate 28g / L, sodium gluconate 10g / L, the temperature of the chemical degreasing is 75 ℃, and the time is 10min; the electrochemical polishing is carried out in the polishing liquid, and the composition of the polishing liquid includes phosphoric ...

Embodiment 2

[0086] This embodiment provides a kind of preparation method of antibacterial and antiviral stainless steel, except that the silver nitrate in the sol A described in step (2) is omitted, that is, the composition of the sol A is butyl titanate 1.2mol / L, iodic acid Sodium 27g / L, dehydrated ethanol 18mol / L, deionized water 20mol / L, diethanolamine 1.15mol / L, other conditions and embodiment 1 are exactly the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com