Antibacterial and antiviral aluminum alloy and preparation method thereof

An aluminum alloy and anti-virus technology, applied in botany equipment and methods, disinfectants, bactericides, etc., can solve the problems of cumbersome operation, unfavorable rapid production, etc., and achieve simple operation, short process, and durable antibacterial and antiviral performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

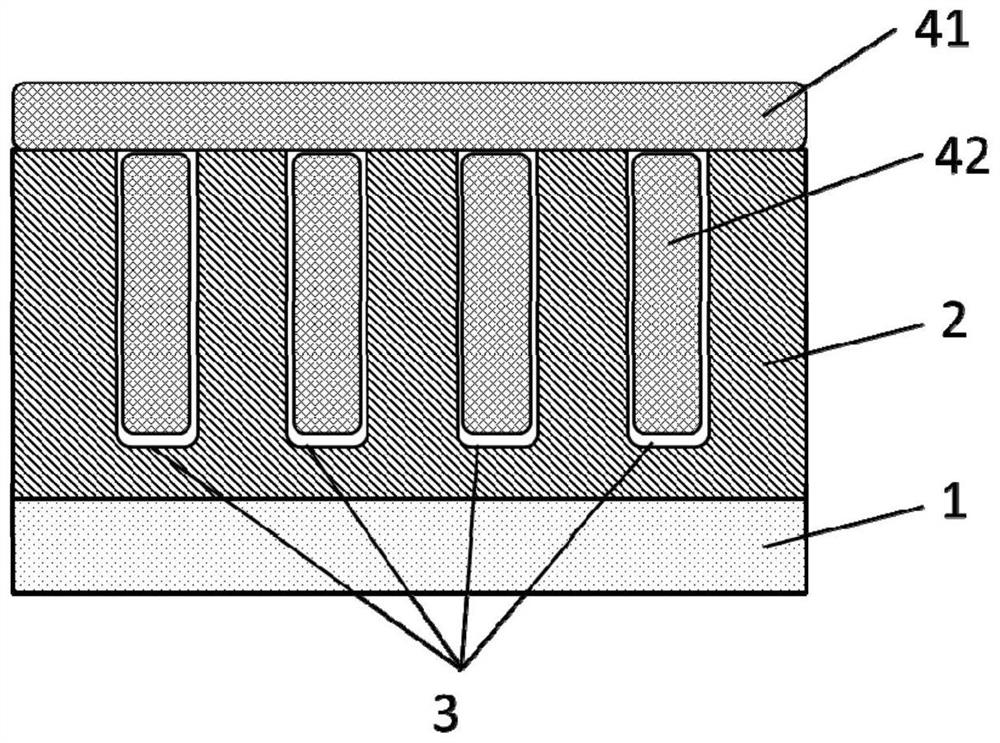

Image

Examples

preparation example Construction

[0070] The preparation method of the antibacterial and antiviral aluminum alloy of the present invention comprises the following steps:

[0071] (1) Anodizing the aluminum alloy, forming an anodized film with micropores on the surface of the aluminum alloy;

[0072] (2) Soak the aluminum alloy obtained by the anodic oxidation in step (1) in sol A, then take out the soaked aluminum alloy and heat it once to obtain the antibacterial and antiviral aluminum alloy crude product;

[0073] (3) soaking the antibacterial and antiviral aluminum alloy crude product described in step (2) in sol B, and then taking out the soaked aluminum alloy for secondary heating to obtain the antibacterial and antiviral aluminum alloy;

[0074] Wherein, the sol A includes butyl titanate, and the sol B includes ribavirin and acyclovir.

[0075] Typical but non-limiting examples of the invention are as follows:

Embodiment 1

[0077] This embodiment provides a method for preparing an antibacterial and antiviral aluminum alloy, the preparation method comprising the following steps:

[0078] (1) First carry out sandblasting, alkali cleaning and pickling to aluminum alloy successively as pretreatment, the particle diameter of the sand used for described sandblasting is 120 orders, and described alkali cleaning adopts the sodium hydroxide solution of 45g / L, at 55 Alkali washing at ℃ for 7 minutes, washing with water and then pickling, the pickling uses 130g / L nitric acid solution, pickling at 25℃ for 1.5min, washing with water and drying; then in 200g / L sulfuric acid solution Carry out anodic oxidation, adopt direct current, use described aluminum alloy as anode, use graphite as cathode, the current density of described direct current is 9A / dm 2 , the power supply voltage is 30V, after anodic oxidation treatment at 15°C for 30 minutes, an anodic oxidation film with micropores is formed on the surface of...

Embodiment 2

[0086] This embodiment provides a method for preparing an antibacterial and antiviral aluminum alloy, except that the silver nitrate in sol A described in step (2) is omitted, that is, the composition of sol A is butyl titanate 1.2mol / L, iodine Na2SO4 27g / L, absolute ethanol 18mol / L, deionized water 20mol / L, diethanolamine 1.15mol / L, other conditions are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com