Antibacterial fresh-keeping material containing nano-silver and preparation method of antibacterial fresh-keeping material

A fresh-keeping material, nano-silver technology, applied in other home appliances, sustainable manufacturing/processing, bio-packaging, etc., can solve problems such as inability to apply fresh-keeping plastic bag film products, combustion residues that do not meet the standard requirements, and poor antibacterial effect , to achieve the effect of prolonging the fresh-keeping period of food, no toxic side effects, and long antibacterial time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

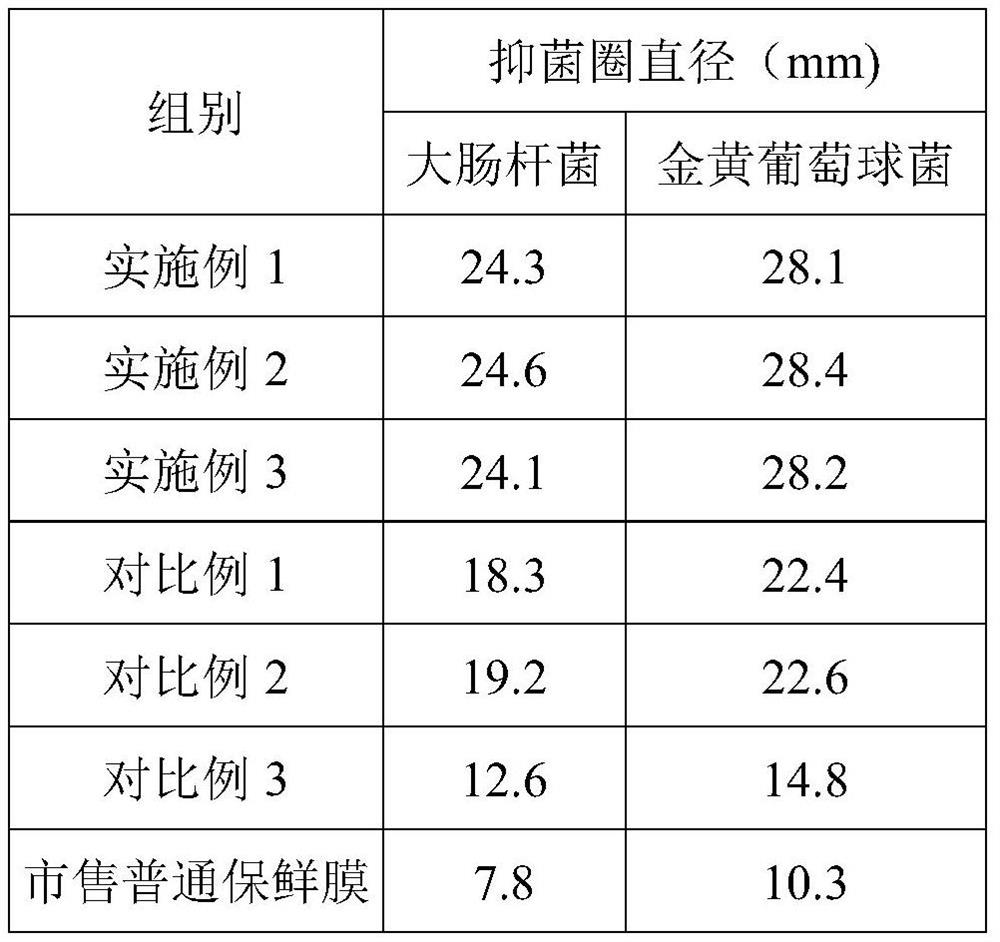

Examples

Embodiment 1

[0033] Embodiment 1 A kind of antibacterial fresh-keeping material containing nano-silver

[0034] The antibacterial and fresh-keeping material containing nano-silver is composed of the following components and parts by weight: 80 parts of polyethylene, 20 parts of dispersant, 5 parts of binder, and 3 parts of composite nano-silver powder.

[0035] The preparation steps of described composite nano-silver powder are as follows:

[0036] S1. Take the rice straw, clean it, chop it into short stems with a length of 2 cm, dry it at 60° C., crush it, and pass it through a 60-mesh sieve;

[0037] S2. Soak the dried rice straw obtained in step S1 in a sodium hydroxide solution with a mass fraction of 15% at room temperature at a weight ratio of 1:5, wash and dry after 24 hours; then at 100°C, Treat with 2% sodium hydroxide and 15% sodium chlorite solution in a weight ratio of 1:3 for 3 hours, wash and dry after cooling to obtain rice straw fiber powder;

[0038]S3. Add the rice stra...

Embodiment 2

[0048] Embodiment 2 A kind of antibacterial and fresh-keeping material containing nano-silver

[0049] The antibacterial and fresh-keeping material containing nano-silver is composed of the following components and parts by weight: 90 parts of polyethylene, 25 parts of dispersant, 8 parts of binder, and 6 parts of composite nano-silver powder.

[0050] The preparation steps of described composite nano-silver powder are as follows:

[0051] S1. Take the rice straw, clean it, chop it into short stems with a length of 3 cm, dry it at 70° C., crush it, and pass it through a 60-mesh sieve;

[0052] S2. Soak the dried rice straw obtained in step S1 in a sodium hydroxide solution with a mass fraction of 15% at room temperature at a weight ratio of 1:8, wash and dry after 24 hours; then at 100°C, Treat with 2% sodium hydroxide and 15% sodium chlorite solution for 3 hours in a weight ratio of 1:5, wash and dry after cooling to obtain rice straw fiber powder;

[0053] S3. Add the rice...

Embodiment 3

[0063] Embodiment 3 A kind of antibacterial fresh-keeping material containing nano-silver

[0064] The antibacterial and fresh-keeping material containing nano-silver is composed of the following components and parts by weight: 100 parts of polyethylene, 30 parts of dispersant, 12 parts of hydroxymethyl cellulose, and 10 parts of composite nano-silver powder.

[0065] The preparation steps of described composite nano-silver powder are as follows:

[0066] S1. Take the rice straw, clean it, chop it into short stems with a length of 4 cm, dry it at 80° C., crush it, and pass it through a 60-mesh sieve;

[0067] S2. Soak the dried rice straw obtained in step S1 in a sodium hydroxide solution with a mass fraction of 15% at room temperature at a weight ratio of 1:12, wash and dry after 24 hours; then at 100°C, Treating with 2% sodium hydroxide and 15% sodium chlorite solution in a weight ratio of 1:6 for 3 hours, cooling, washing and drying to obtain rice straw fiber powder;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com